Plastic dispensing container having reduced moisture penetration and method for same

a technology of dispensing tube and dispensing container, which is applied in the direction of flexible containers, thin material handling, packaging, etc., can solve the problems of product spoilage or pre-mature curing, pre-mature moisture penetration or infiltration, and prior art dispensing tube containers often do not prevent moisture penetration to a sufficient degree, so as to reduce the permeation of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

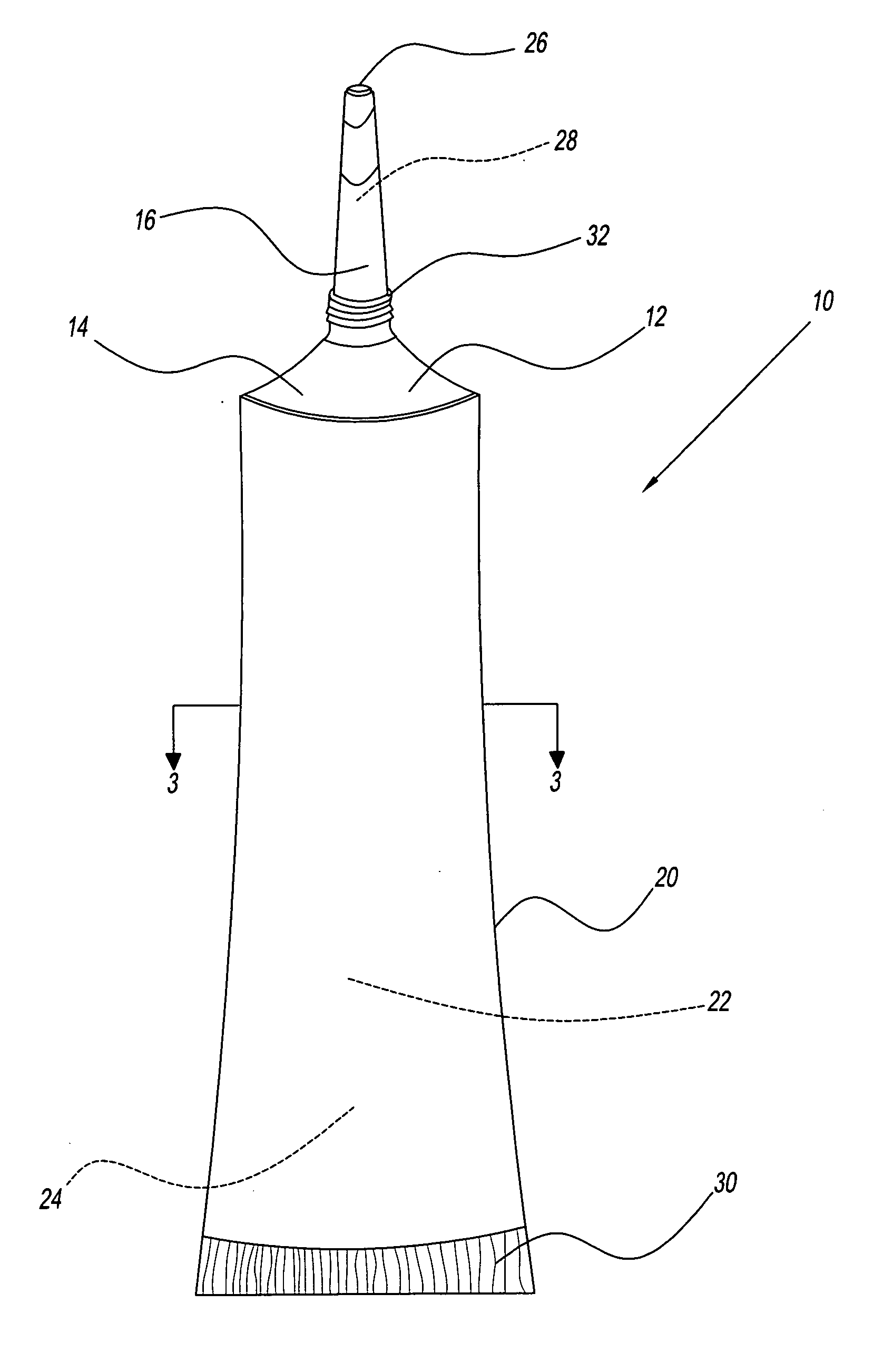

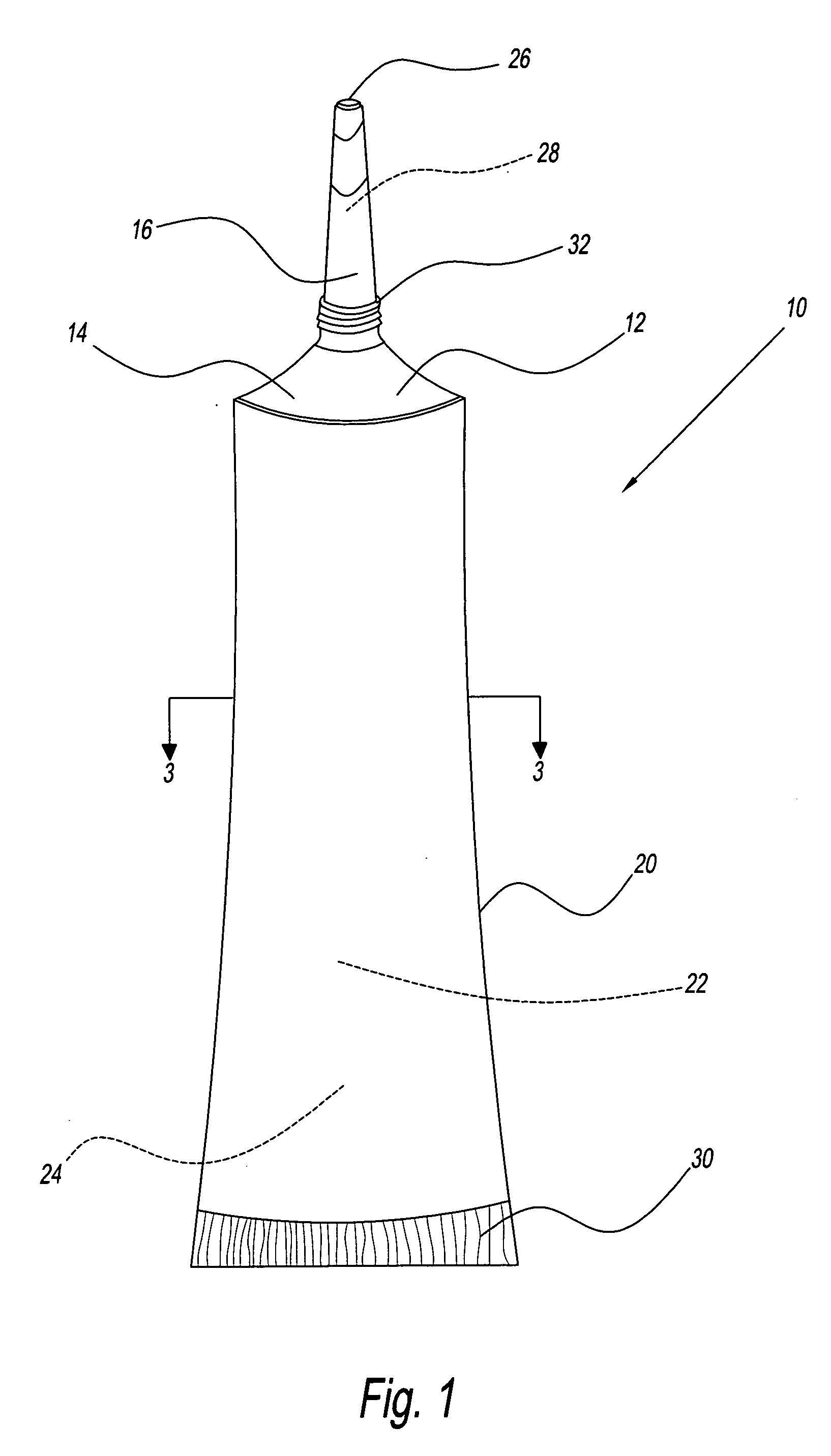

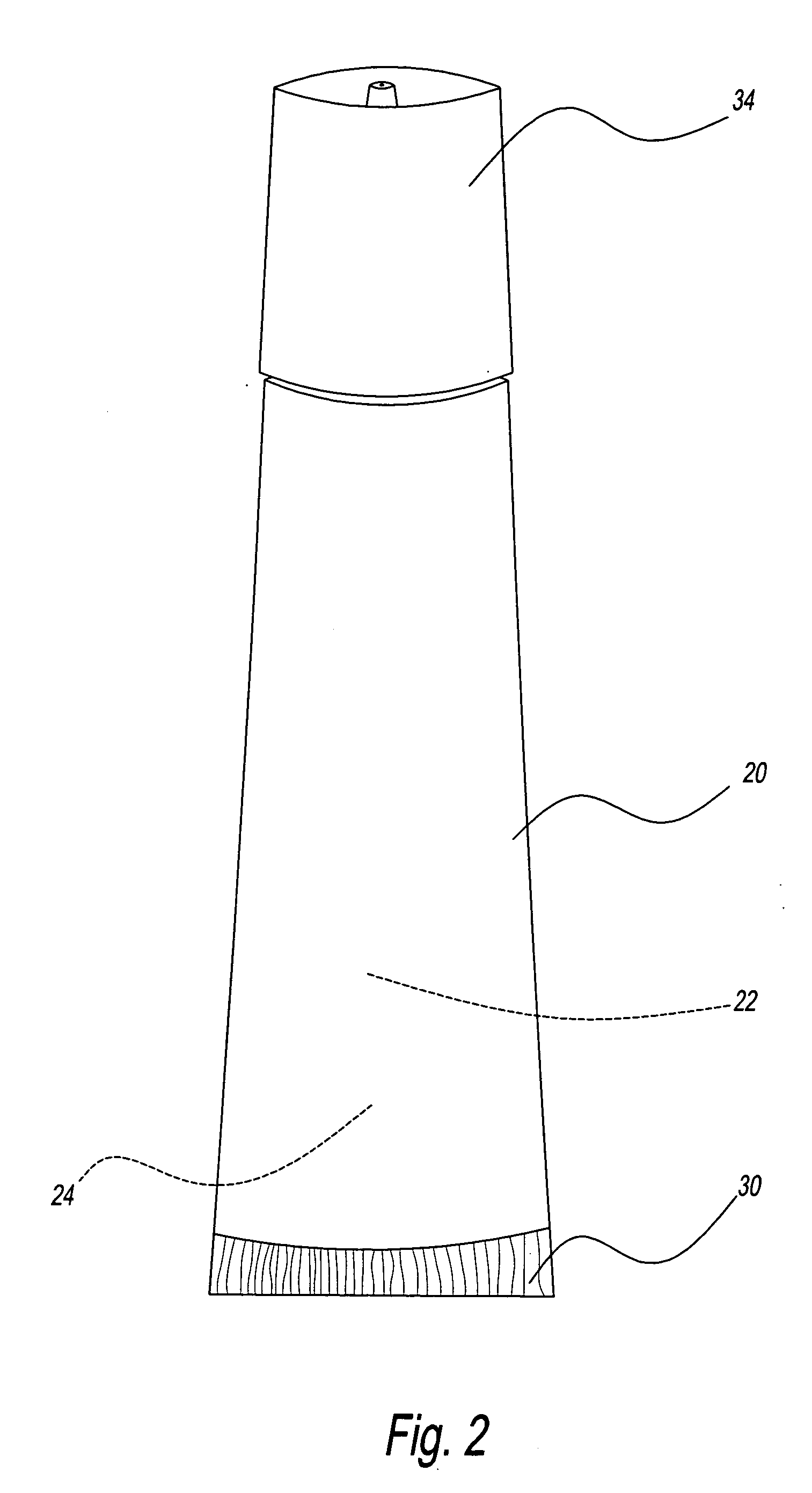

[0014] The head of the dispensing tube container of the present invention has a dessicant therein in an amount sufficient to reduce the rate of permeation of moisture through the head relative to the rate without the dessicant. The dessicant is preferably present in the head in an amount about 0.1 to about 25 wt %, more preferably about 0.5 to about 10 wt %, and most preferably 0.5 to about 5 wt % based upon the total weight of the head. The dessicant may be present in a portion of or the entirety of the head. The dessicant may be present in either or both of the shoulder and the neck. Preferably, the dessicant is admixed substantially homogeneously throughout the entirety of the head. Alternately, the dessicant may be present in one or more film layers at the interior or exterior surfaces of the head.

[0015] The dessicant may be any substance which reduces the rate of permeation of moisture (water vapor) when dispersed in the head. The dessicant may reduce the rate of permeation by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com