Electrical connector having protecting protrusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

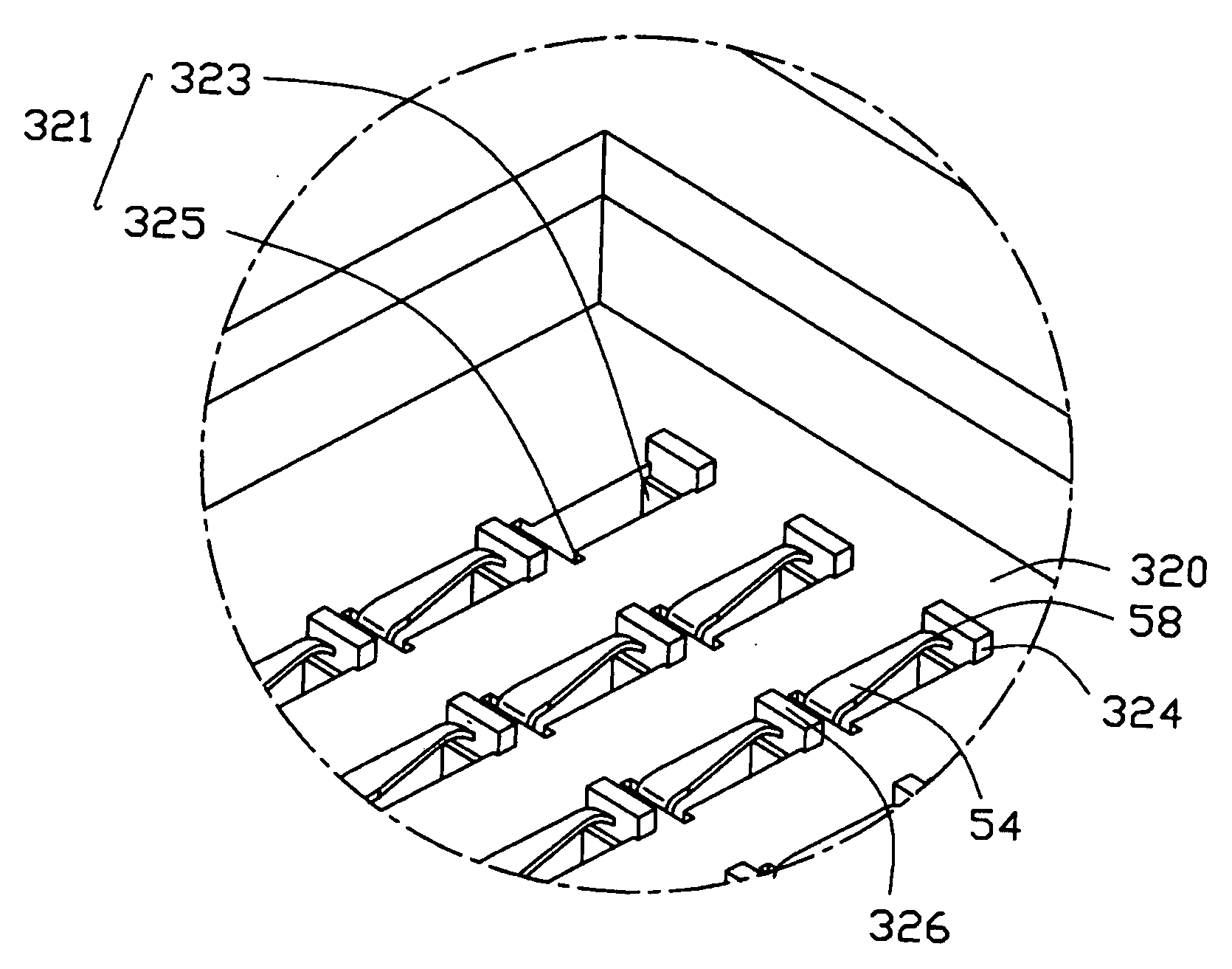

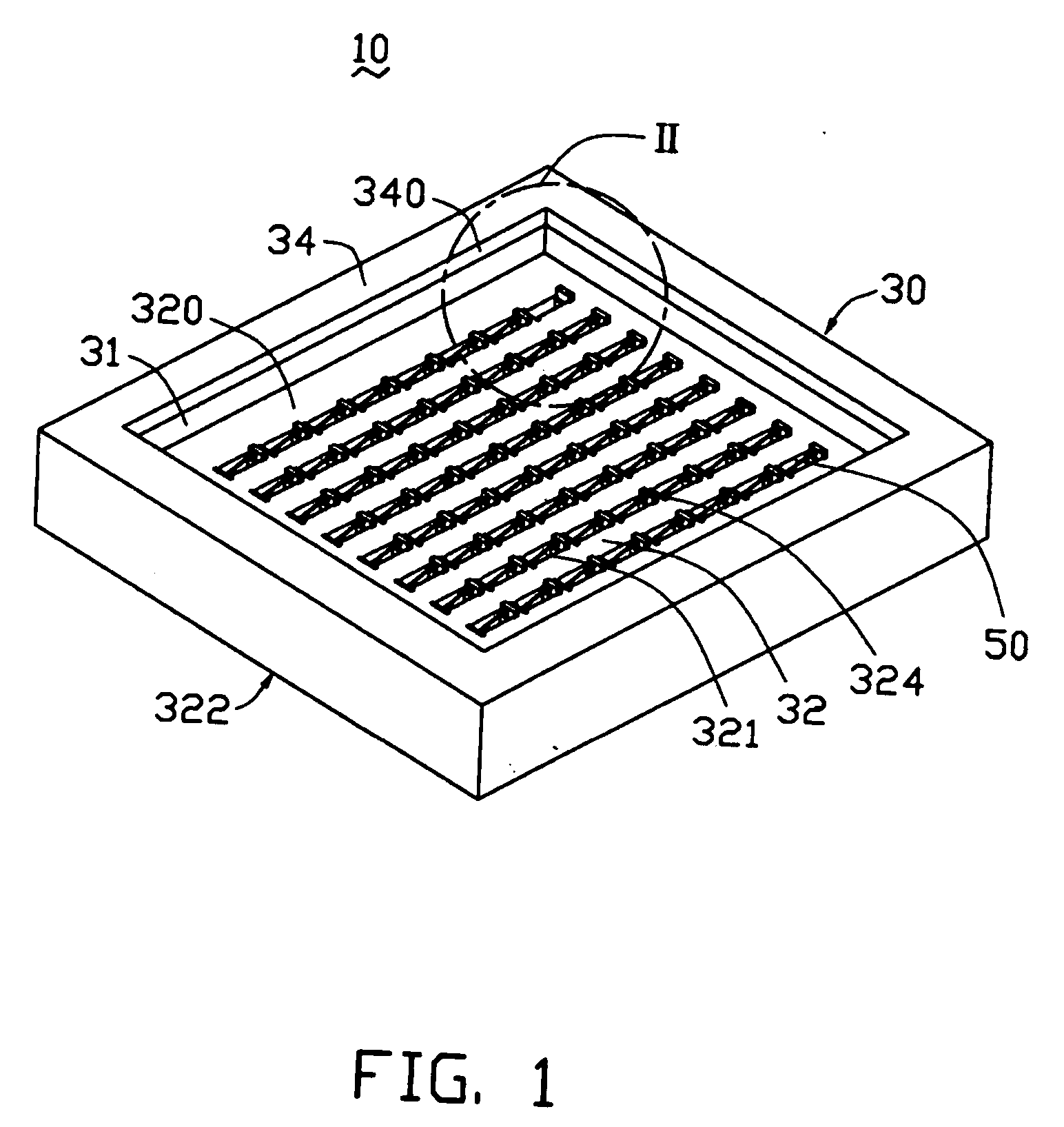

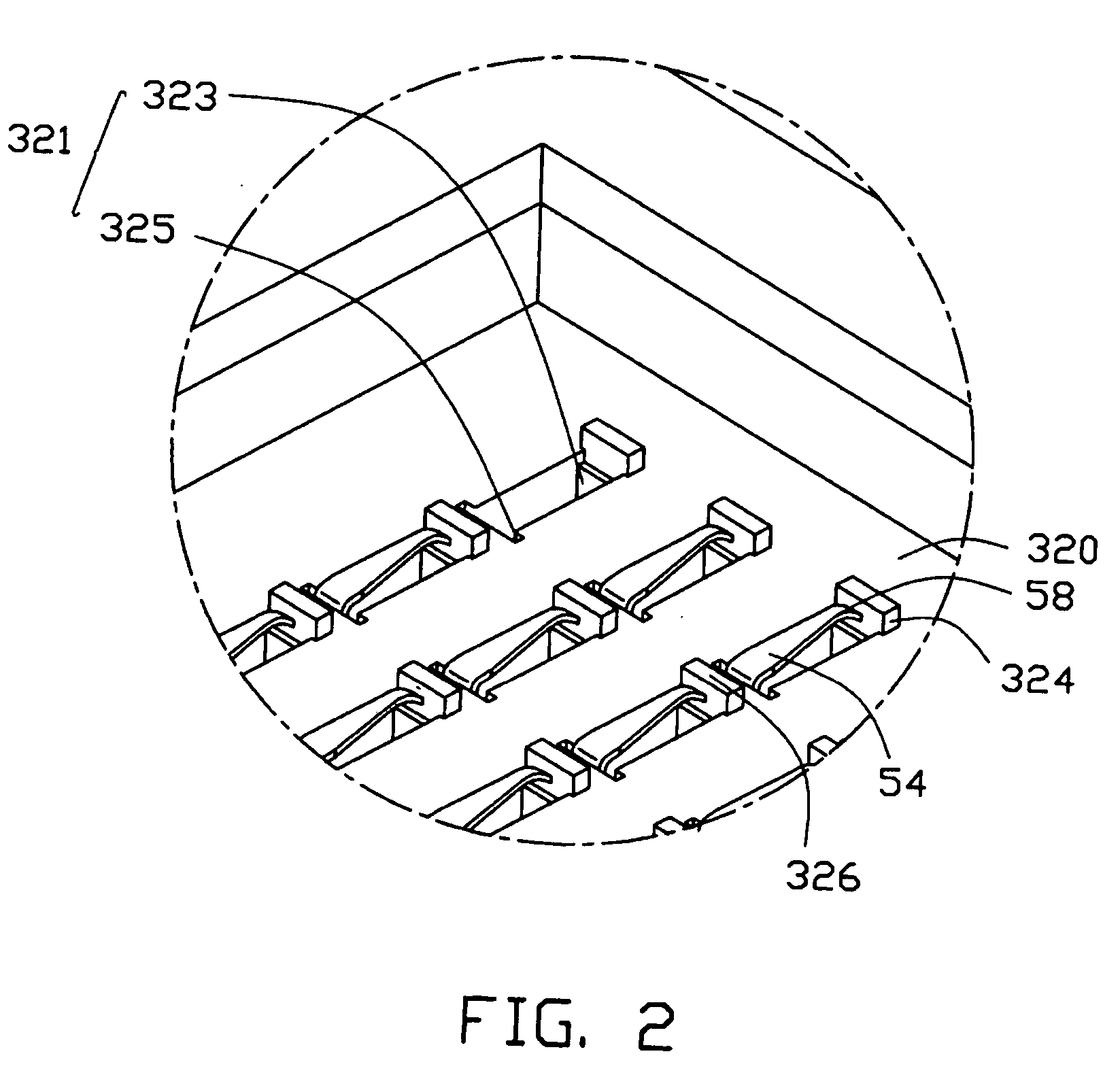

[0016] Reference will now be made to the drawings to describe the present invention in detail.

[0017] Referring to FIG. 1, an LGA connector 10 in accordance with a preferred embodiment of the present invention is provided for electrically connecting a CPU chip 80 to a PCB 90 (best seen in FIGS. 4 and 6). The LGA connector 10 may, of course, be applied in other environments such as for electrically interconnecting two PCBs and so on. The connector 10 comprises a rectangular insulative housing 30 and a plurality of terminals 50 received in the housing 30.

[0018] The housing 30 is configured with a bottom wall 32 and four side walls 34 extending upwardly from peripheries of the bottom wall 32. A receiving cavity 31 is defined between the bottom wall 32 and the side walls 34, for accommodating the CPU chip 3 therein. Guiding slant surfaces 340 are formed on the side walls 34 around a top mouth of the cavity 31, for facilitating insertion of the CPU package 90 into the cavity 31.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com