Angle detector with self-calibration capability

a detector and self-calibration technology, applied in the field ofangle detectors, can solve the problems of limiting the amount of size reduction possible, the coaxiality is generally not perfect, and the angle data obtained from the position of the scale line is error-prone, so as to achieve accurate measurement stably over a long period, and the effect of easy calibration work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

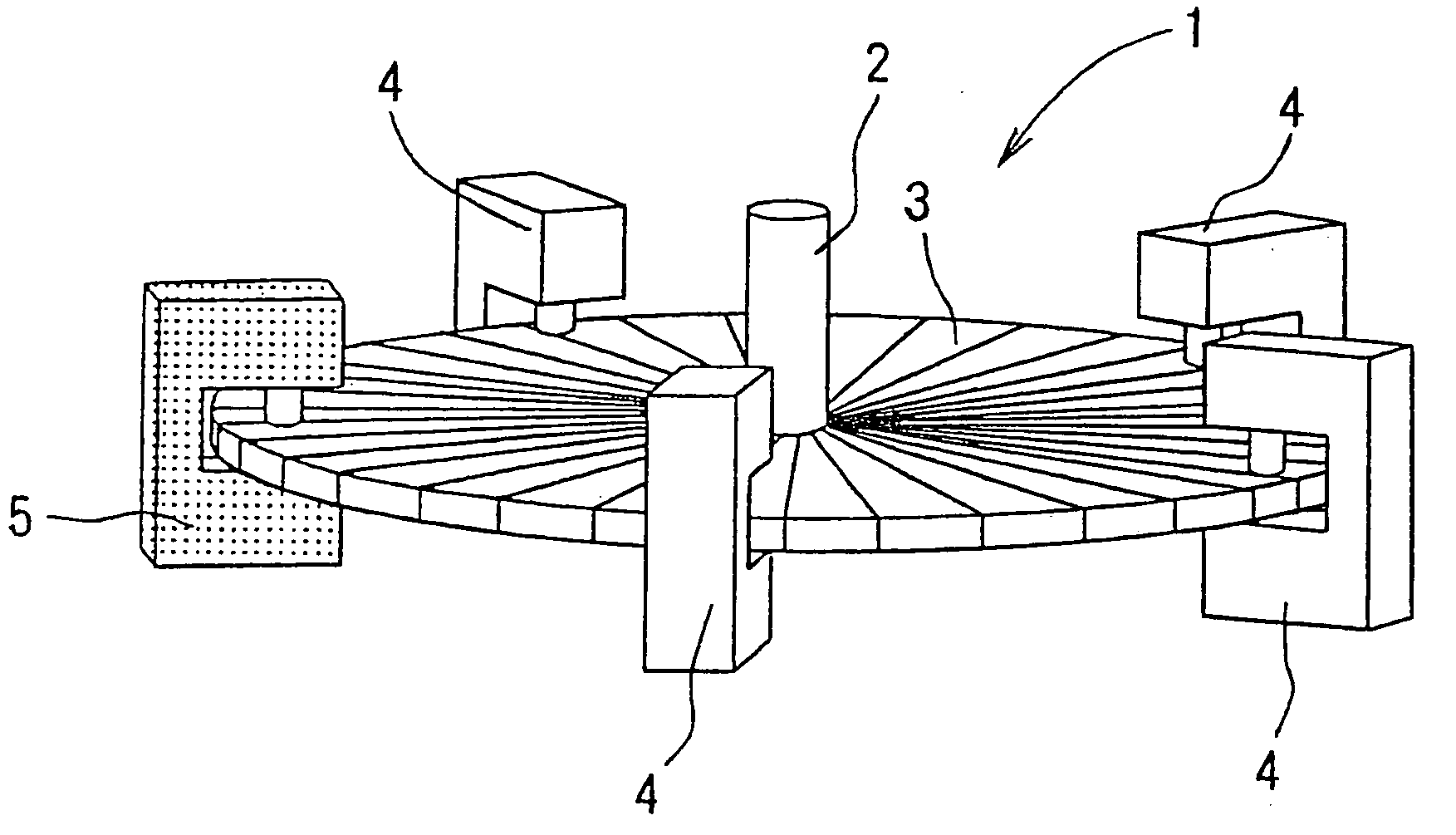

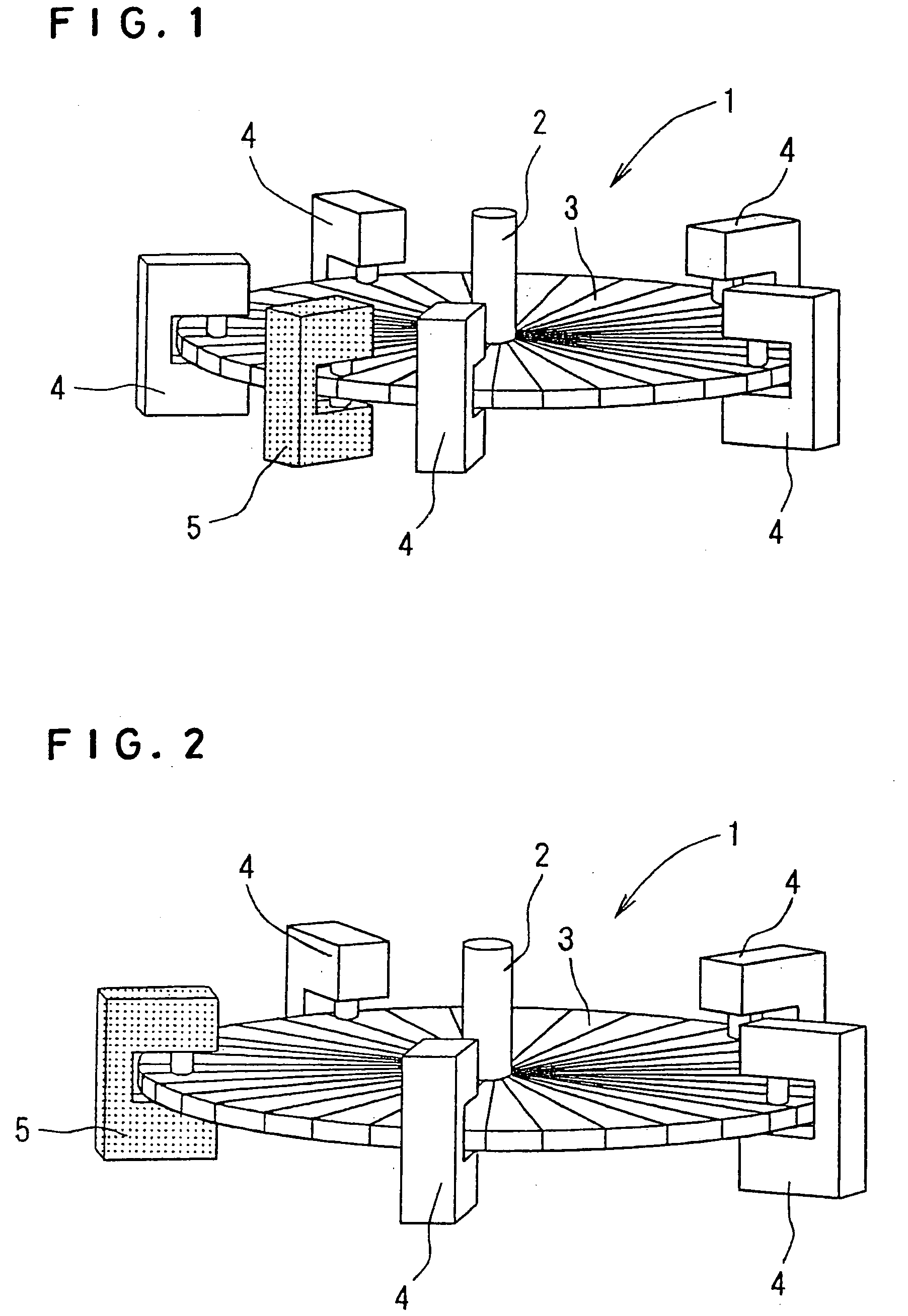

[0038] The degree to which the size of the angle detector shown in FIG. 1 can be reduced is limited because when the second scale read head 5 is installed among the first scale read heads 4, 4 . . . , inter-head interference is apt to arise if the size of the angle detector scale disk is made too small. Therefore, as shown in FIG. 2, in the second embodiment, one of the first scale read heads is made to assume the role of the second scale read head. In other words, the second scale read head 5 is installed at the location of one of the first scale read heads 4, 4 . . . spaced equidistantly around the periphery of the scale disk 3 to replace the same.

first embodiment

[0039] In this arrangement of the scale read heads, as in the first embodiment, where the first scale read heads are designated A1, A2, A3, . . . , ANH, and the second scale read head serving as a reference head is designated B1, the scale angle signals Bi and Ai,j detected by these heads can be expressed by the following equations.

Bi=bi

Ai,j=ai+(j−1)NG / NH [0040] NG: Total number of scales on a rotary encoder [0041] NH: Total number of heads [0042] j: Head number, j=1, 2, . . . , NH [0043] i: Scale number, i=1, 2, , NG

[0044] Since Bi=Ai,j when the first head is considered the reference head, the differences SAi,j1 between the angle signal output by the reference head B1 and the angle signals Ai, j and the average SAVj thereof can be expressed by the following equations.

Sai,j=Ai,1−Ai,j=ai−ai+(j−1)NG / ND

SAVi=1ND∑j=1NDSAi,j=ai-1ND(ai+ai+NG / ND+ai+2NG / ND+…+ai+(j-1)NG / ND)

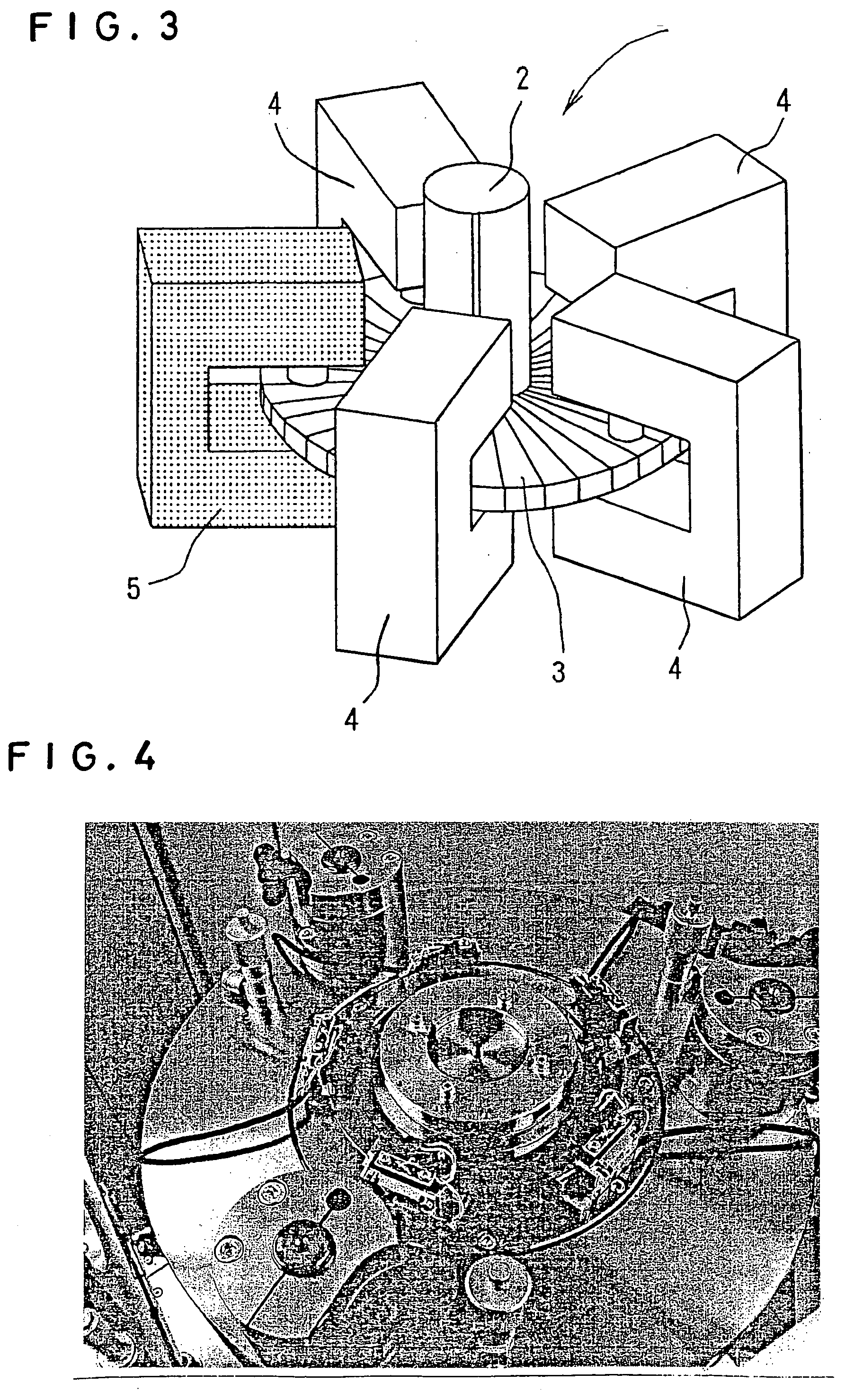

[0045] As exemplified in FIG. 3, this configuration minimizes the spacing required among the heads, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com