Apparatus for vacuum packages and method of controlling it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

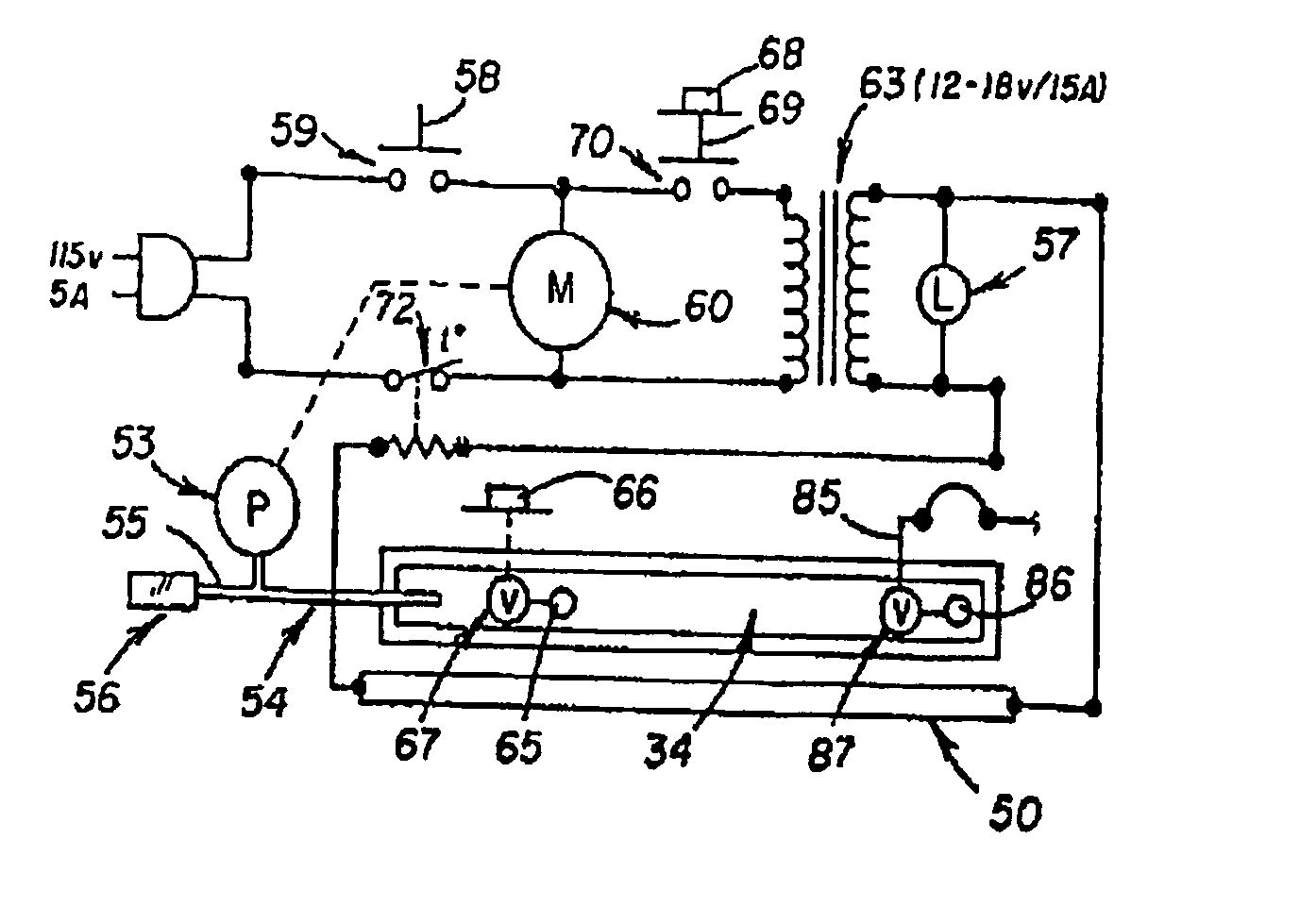

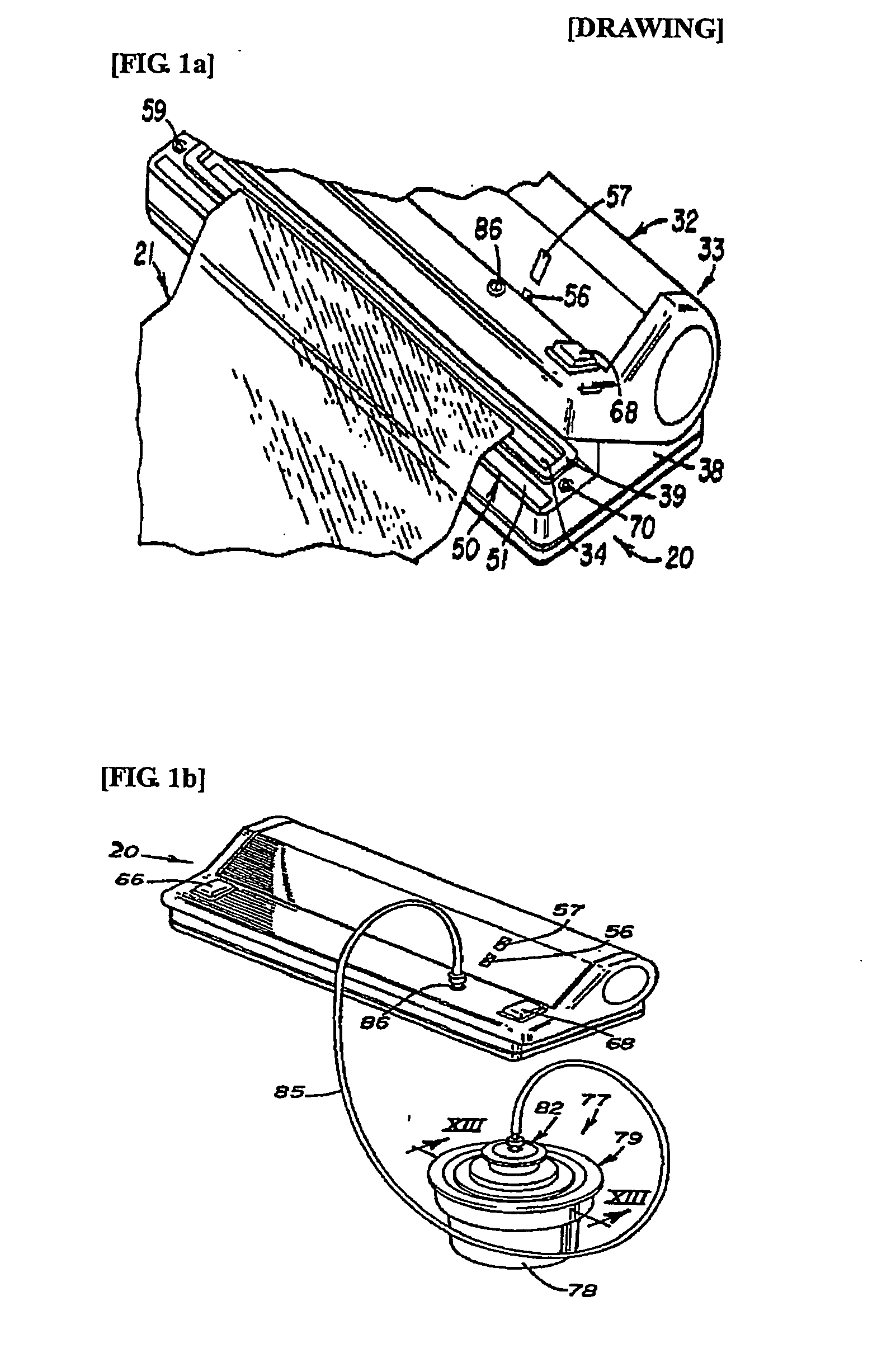

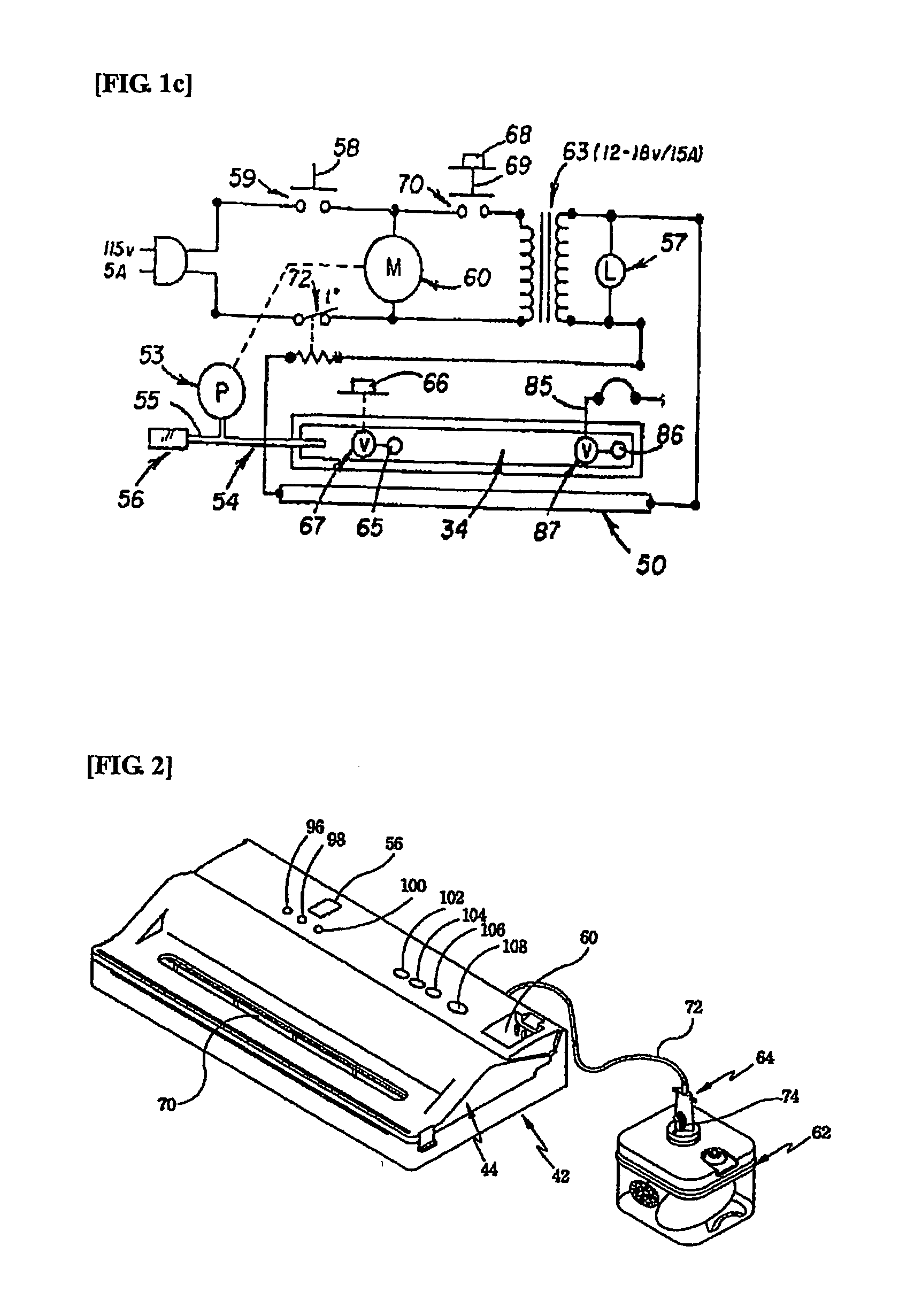

[0027] Now, an explanation of the preferred embodiments of the present invention will be in detail given with reference to attached drawings. FIGS. 3a to 8b show the preferred embodiments of a vacuum sealing apparatus 100 and a method according to the present invention. First of all, an explanation of the vacuum sealing apparatus 100 will be in detail given.

[0028] As shown in FIGS. 3a and 4, the vacuum sealing apparatus 100 includes an upper casing 200, a lower casing 300, a vacuum chamber 400, a vacuum pump 500, a heater 600, a hose assembly 700 and a digital control unit 800. Thereby, a plastic bag or a container 901 is vacuumed by means of the vacuum sealing apparatus 100. In some cases, the vacuum sealing apparatus can be manufactured only for the purpose of the plastic bag, and desirably, the vacuum pump 500, the heater 600 and the digital control unit 800 are housed in the lower casing 300. The upper casing 200 is pivoted by the lower casing 300 in such a manner as to be open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com