Automatic system for taking up and handling a connecting towrope between a tugboat and a towed vessel

a technology of automatic system and tow rope, which is applied in the direction of waterborne vessels, towing/pushing equipment, vessel parts, etc., can solve the problems of falling into disuse, unchanged working methods, and inability to seek liability of tugboat companies, so as to improve understanding and ensure the safety of the crew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

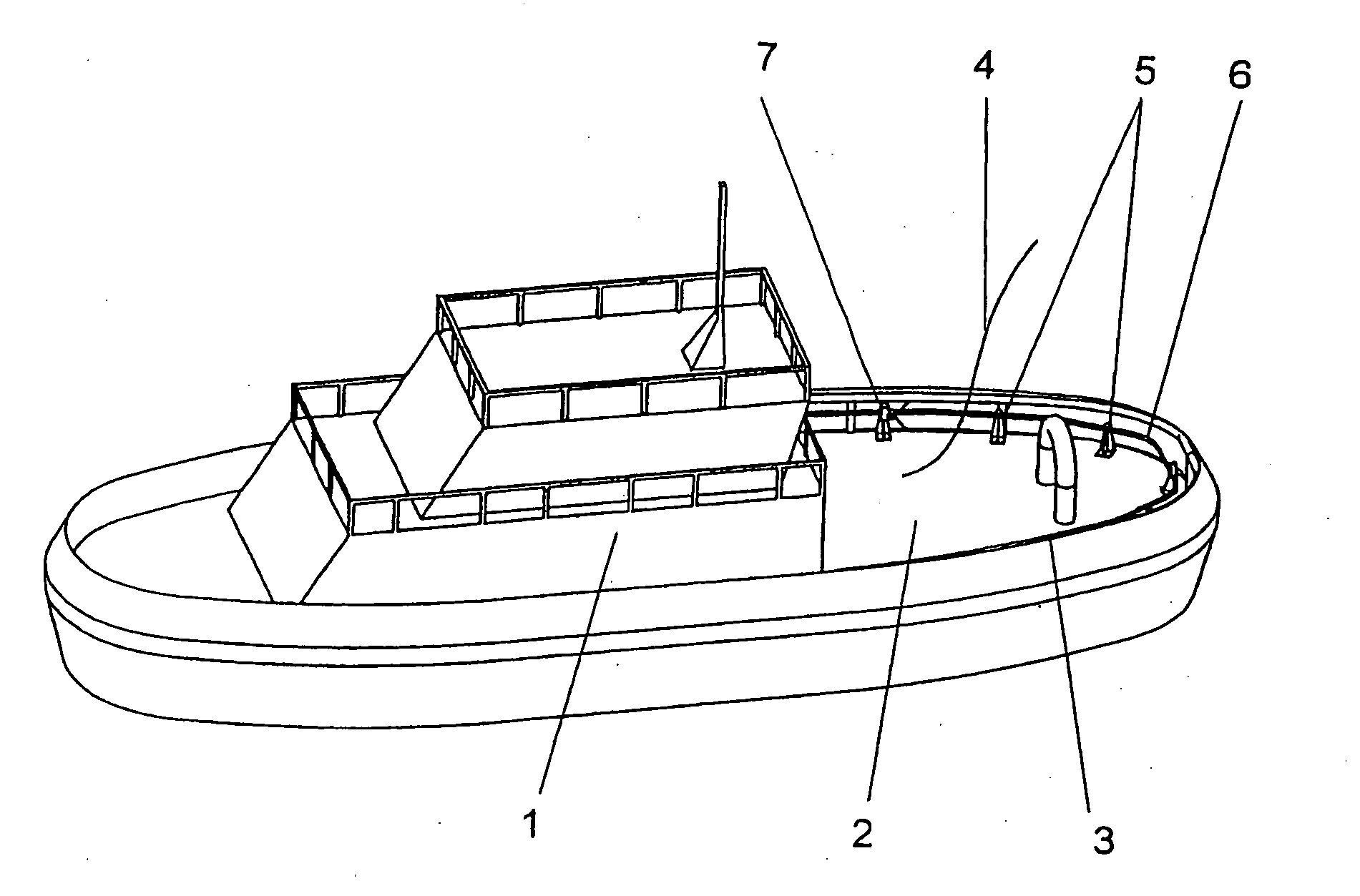

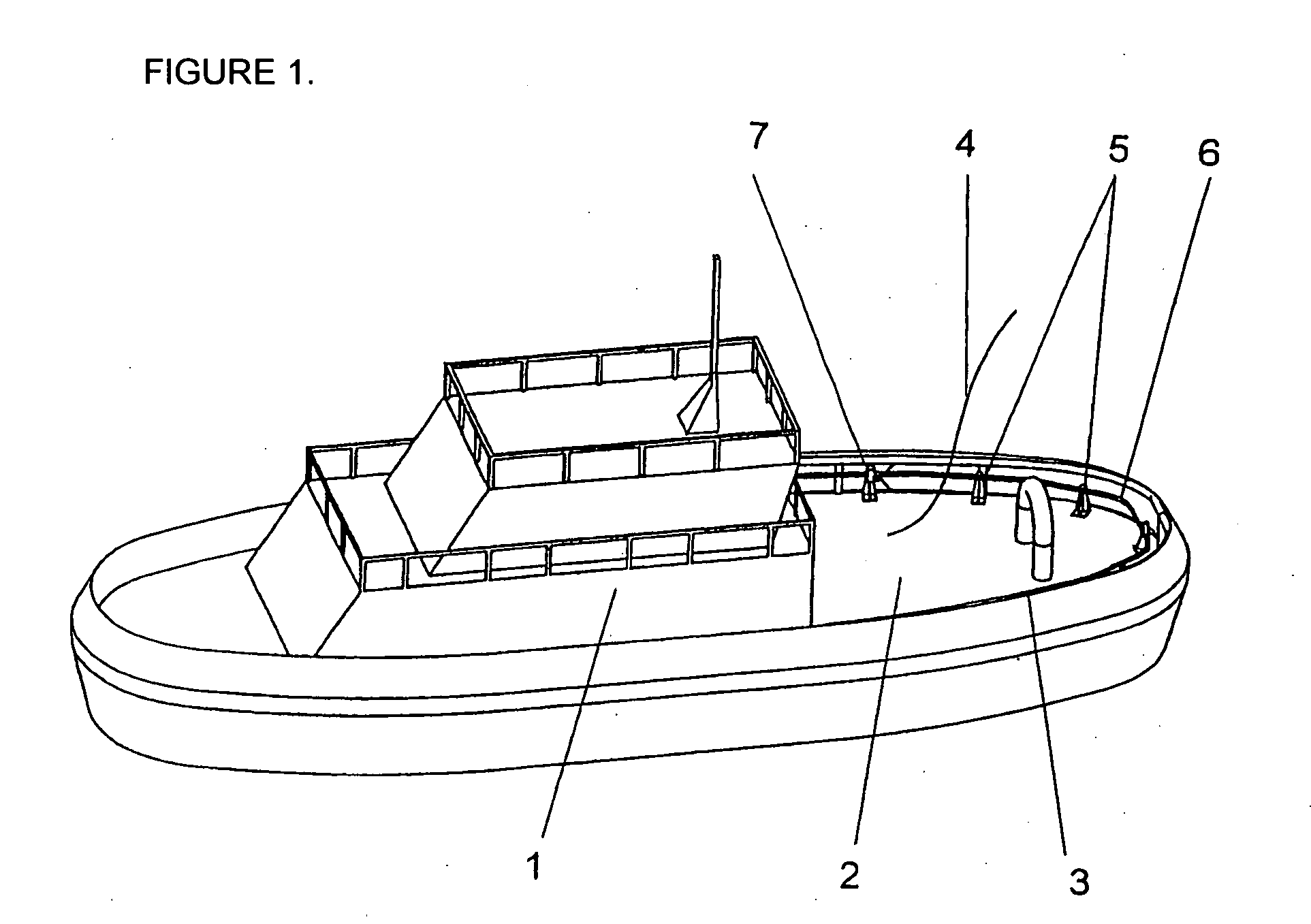

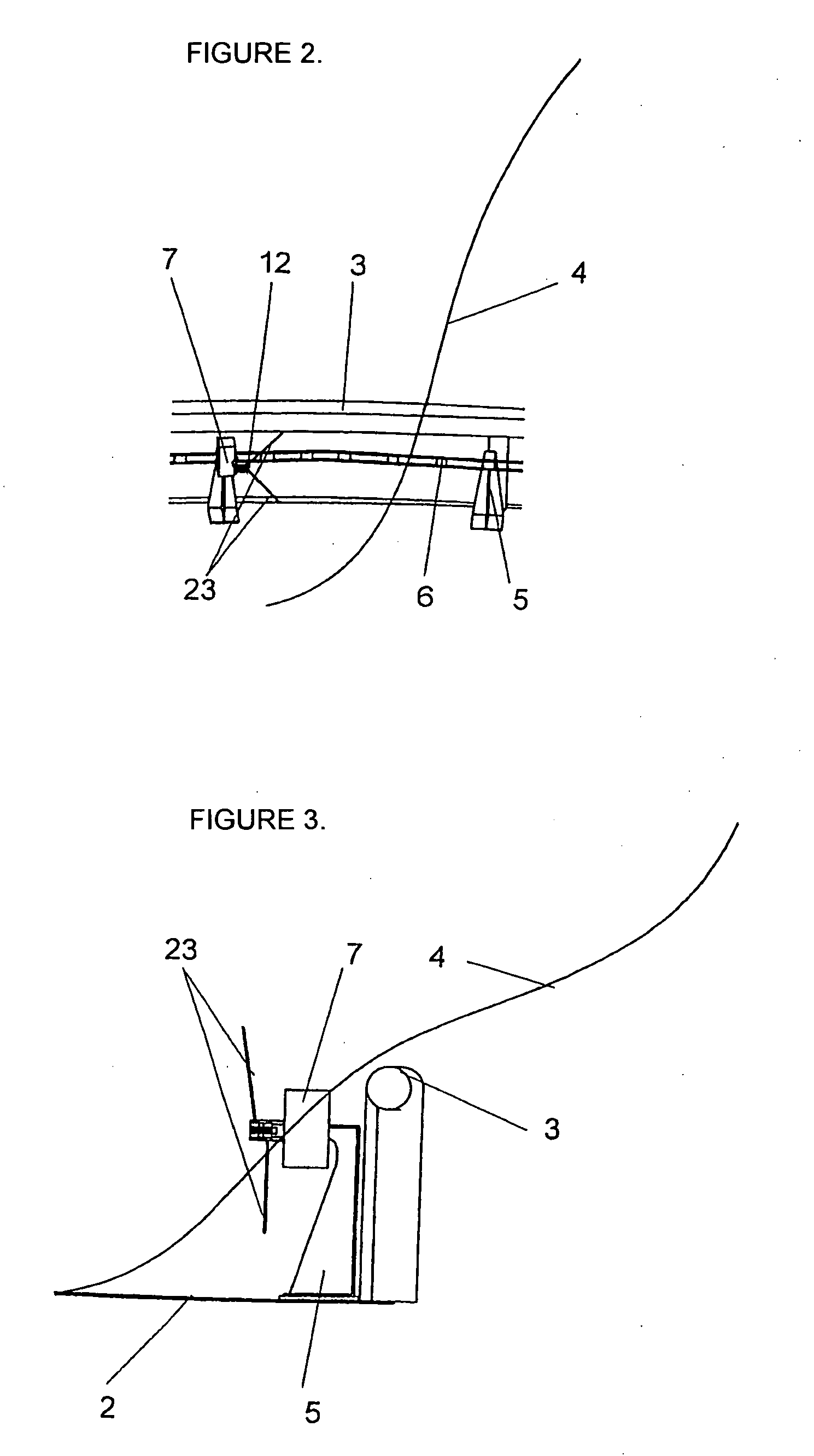

[0013] The automatic system for taking up and handling a connecting towrope between a tugboat and a towed vessel of the present registration is characterized in that it comprises great advantages without meaning any change whatsoever to the overall connecting process disclosed above corresponding to the current state of the art. The process will continue to be the same and the changes made by the new invention mainly affect the fact that the presence of a crew member on the deck of the tugboat for taking up the towrope and fastening it to the tow cable is not required since this operation is carried out by a fastening carriage.

[0014] Said fastening carriage carries out the following operations: [0015] 1. Detecting the presence of the towrope at the level of the gunwale where it is supported after having been launched from the vessel to be towed. [0016] 2. Fixing the towrope with the clamp. [0017] 3. Releasing the clamp from the carriage. [0018] 4. Returning to its rest position unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com