Anchoring device

a technology of anchoring device and screw head, which is applied in the direction of flooring, building reinforcements, construction, etc., can solve the problems of reducing the resistance of the head of the fastening screw and/or the nail between the boards, affecting the stability of the board, so as to achieve the effect of easy cracking, easy cracking, and increased resistance to cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

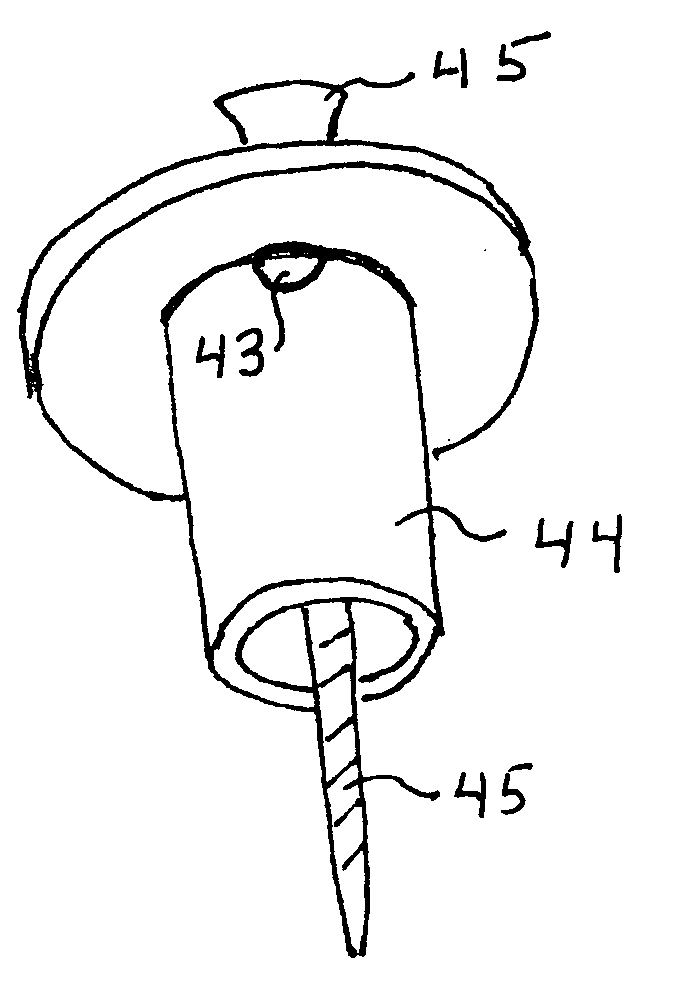

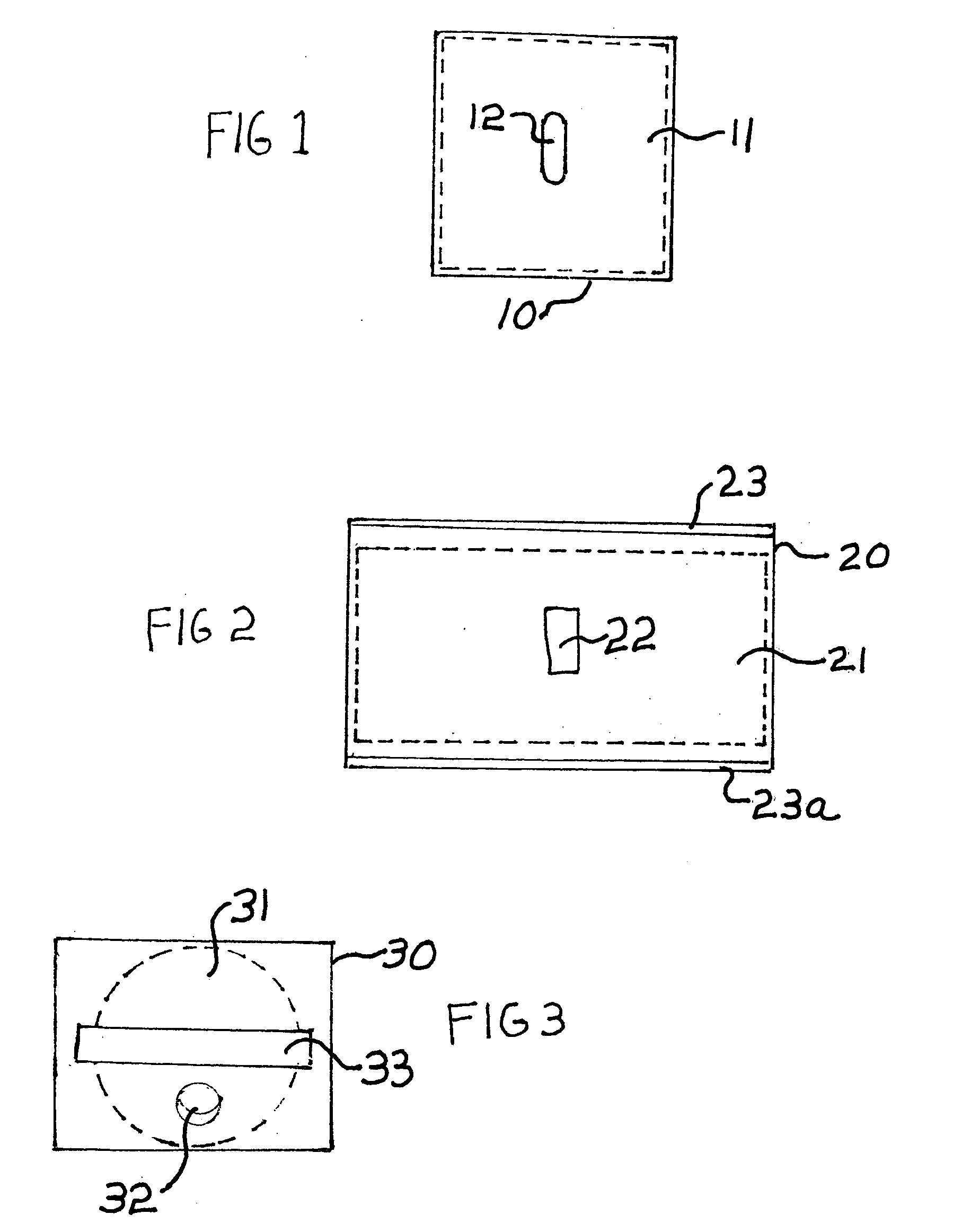

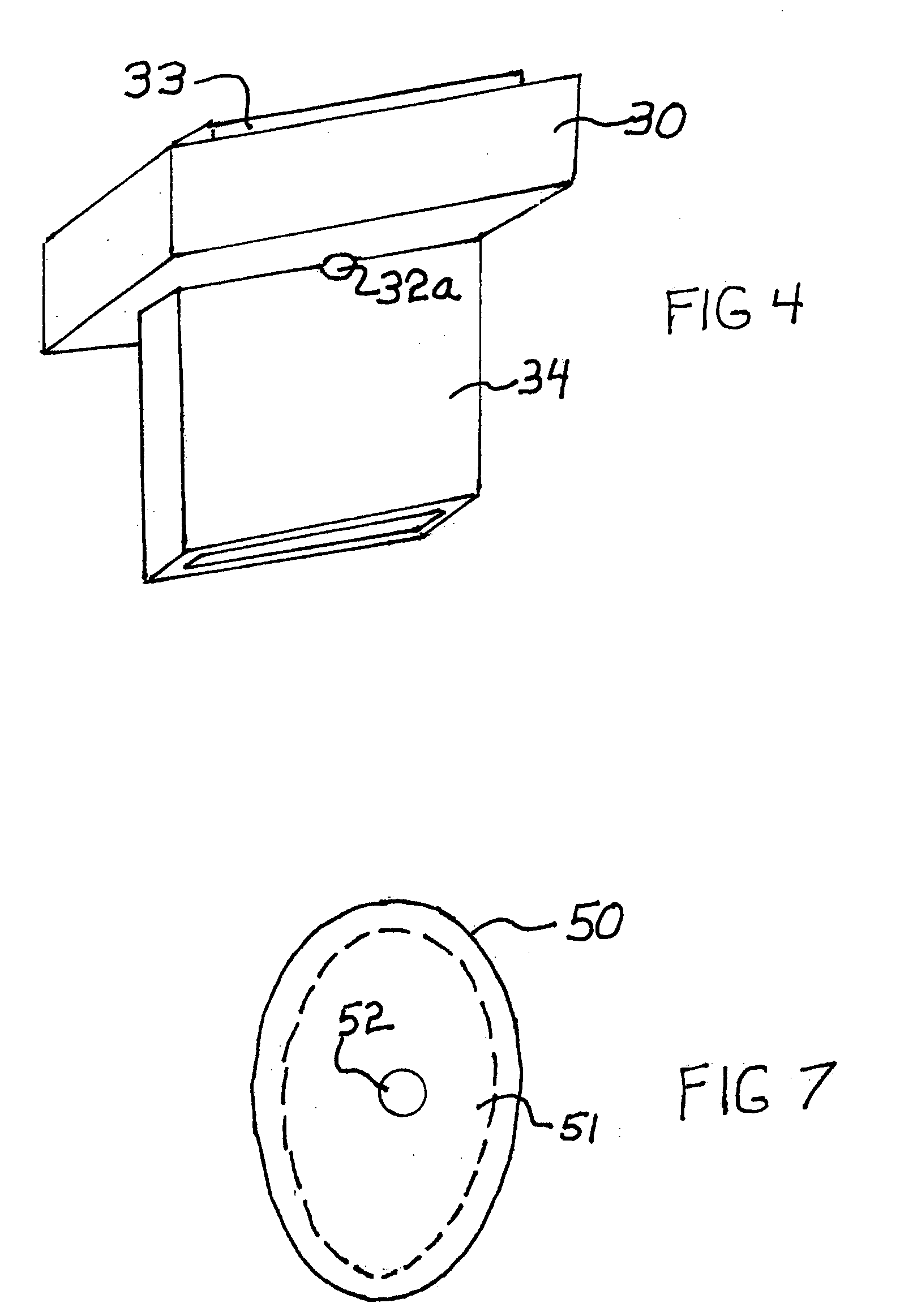

[0039] Referring now to FIG. 1 wherein is illustrated a top plan view of an embodiment of the anchoring device of the invention having a generally square top element 10, with the metallic element 11 being outlined in dotted line, and also being generally square, having an oblong fastening opening 12 therethrough. This arrangement of the invention shows plastic surrounding the sides and exterior peripheral edge of metallic element, with the peripheral edge of the metallic element at a generally central opening not being covered by plastic. This embodiment is generally desirable for use with flat laid boards collapsible hollow rectilinear shoulder 33 extending upwardly from the top side of the top element and collapsible hollow rectilinear vertical element 34 extending downwardly from the underside thereof. This embodiment is particularly preferred for use with flat laid boards which undergo significant climatical dimensional changes. The offset placement of the fastening opening allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com