Container with adjustable inner partitions

a container and inner partition technology, applied in the field of special containers, can solve the problems of affecting the contents of the box in a negative way, and achieve the effect of convenient positioning and convenient alignmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention concerns a container suitable for securely holding and transporting one or more substantially rectangular products. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be obvious, however, to one skilled in the art that the present invention may be practiced without these specific details. Some well-known methods and structures have not been set forth in order not to unnecessarily obscure the description of the present invention.

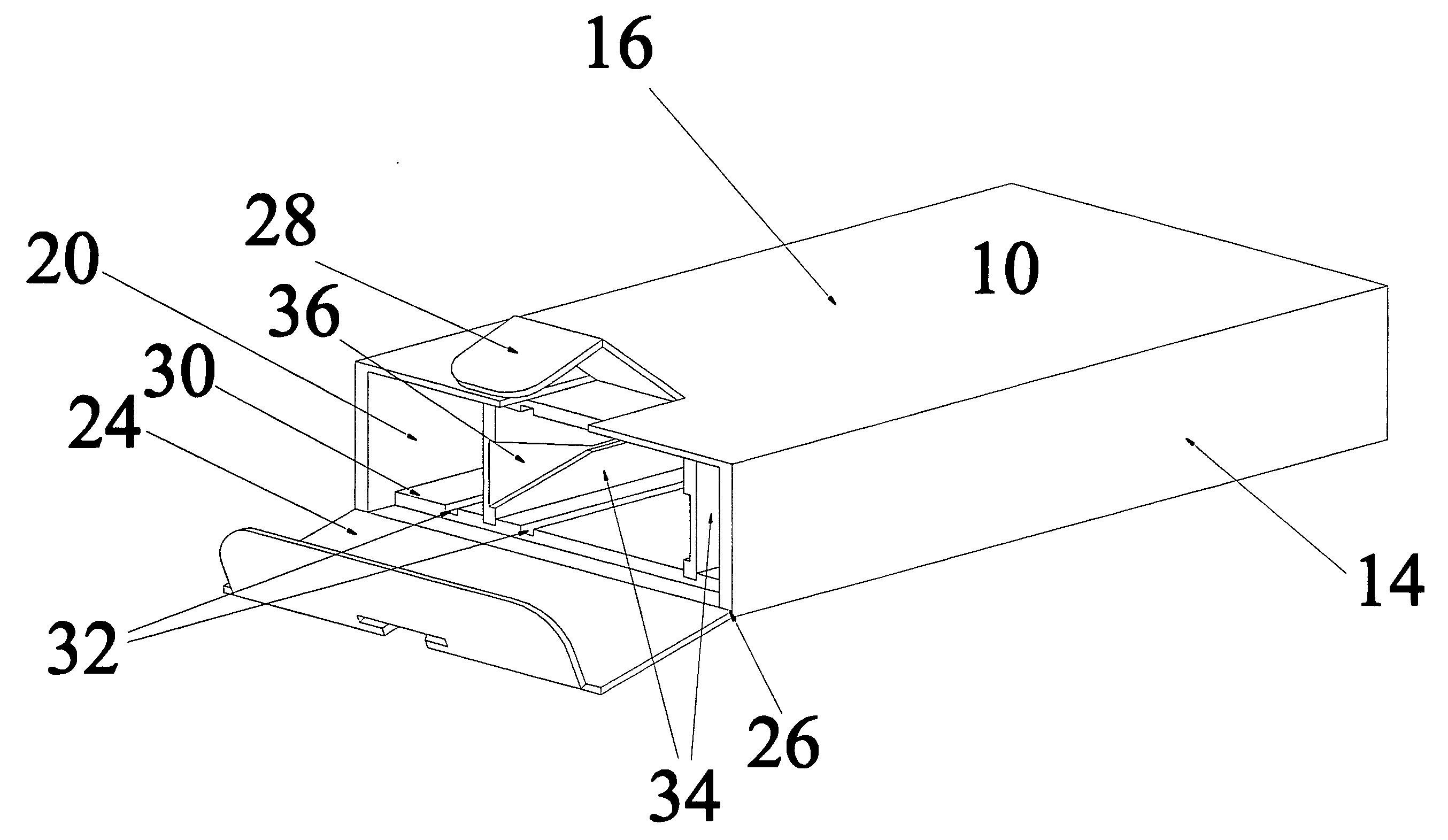

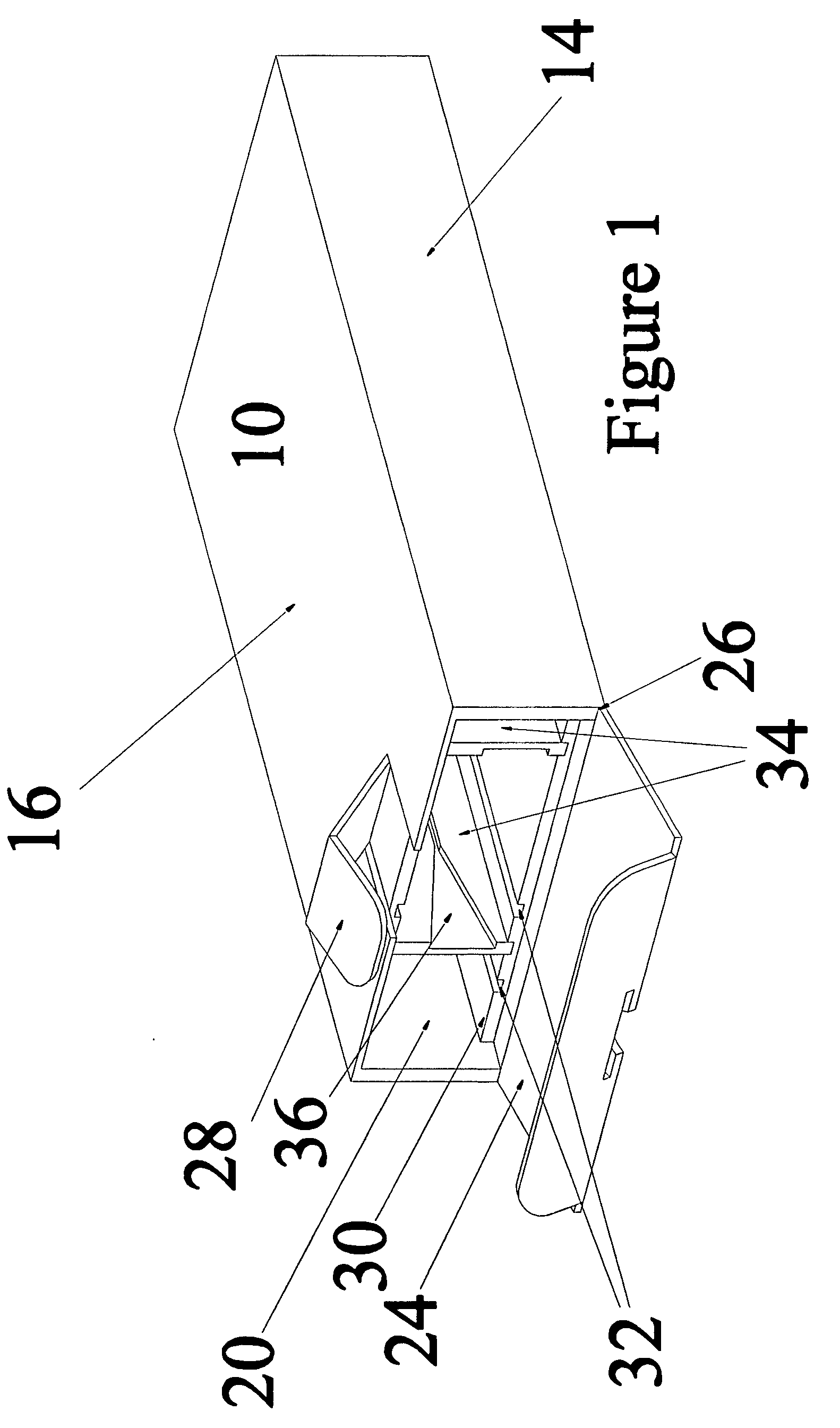

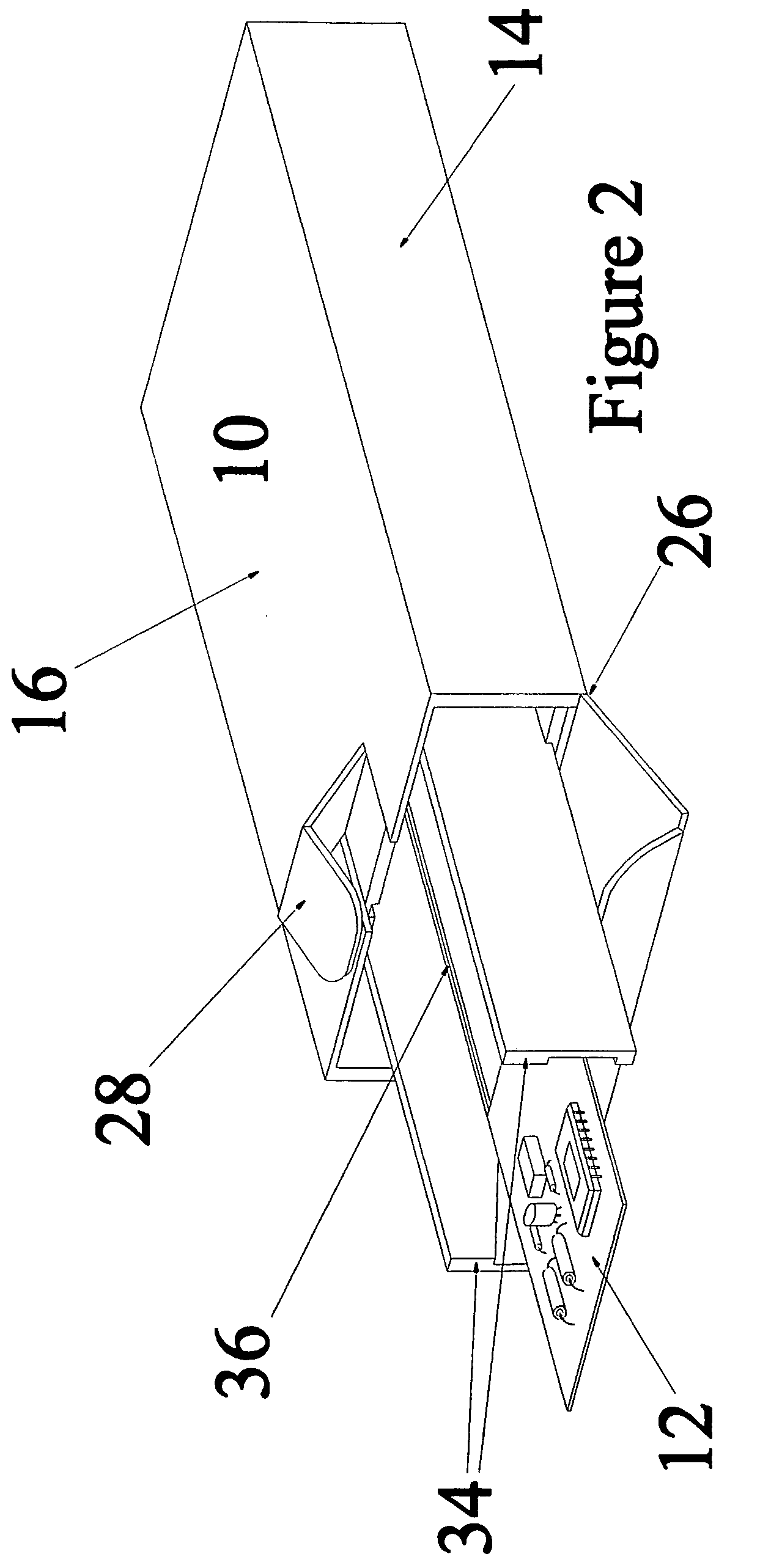

[0028] As can be seen in FIGS. 1 and 7, the container 10 claimed herein includes a top wall 16 opposing a bottom wall 18, two opposing side walls 14, a back wall 22 and a front wall 24. The front wall 24 can be moved between a position in which the container 10 is open, as shown in FIGS. 1-5, and a closed position as shown in FIG. 6. A number of closing mechanisms 28 are suitable for holding the front wall 24 in a closed position. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com