Container with a safety seal

a technology of container and safety seal, which is applied in the direction of container lid, cap, etc., can solve the problems of complicated and difficult handling, and achieve the effect of convenient opening of the container, convenient placement, and convenient placemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

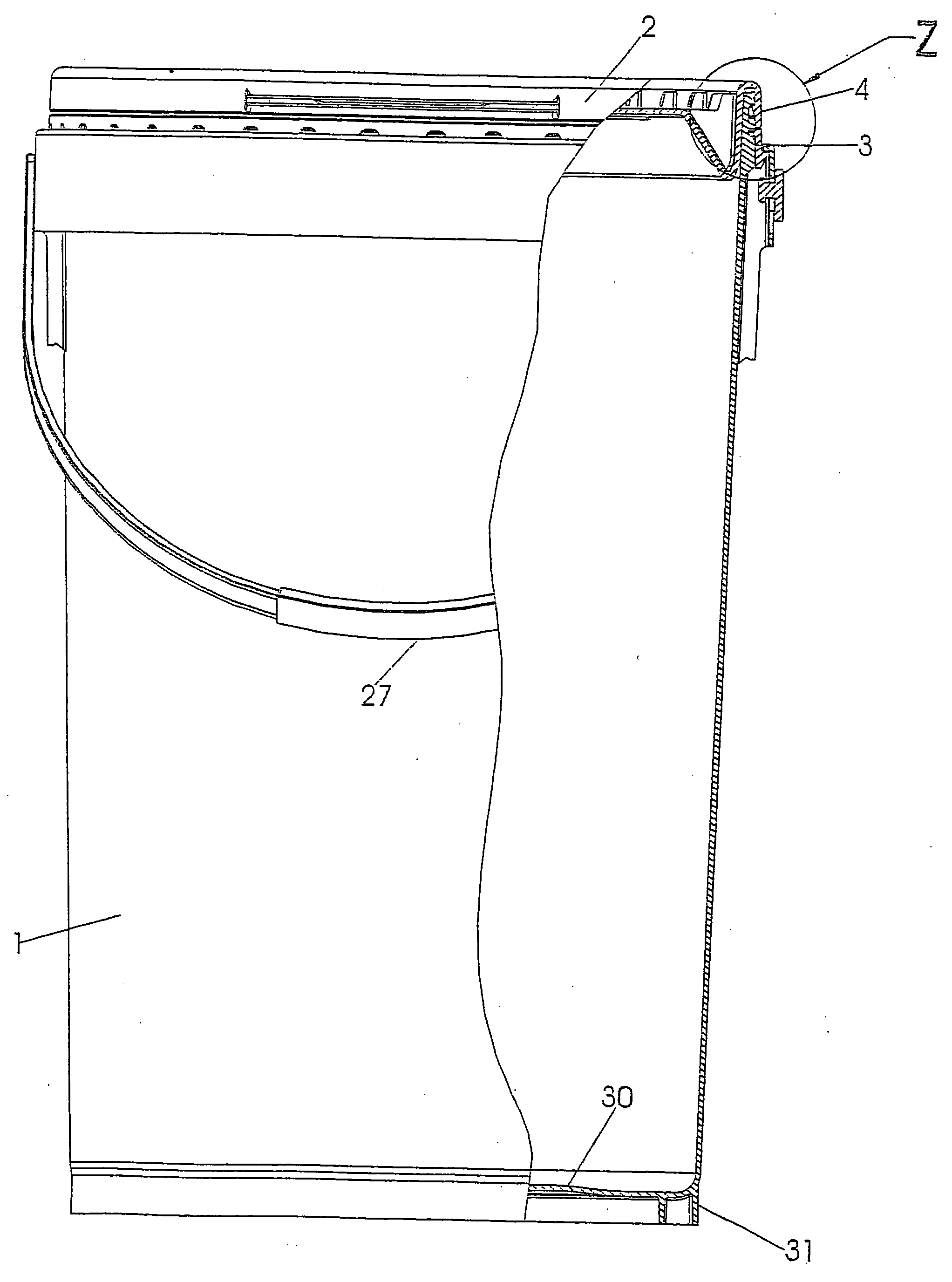

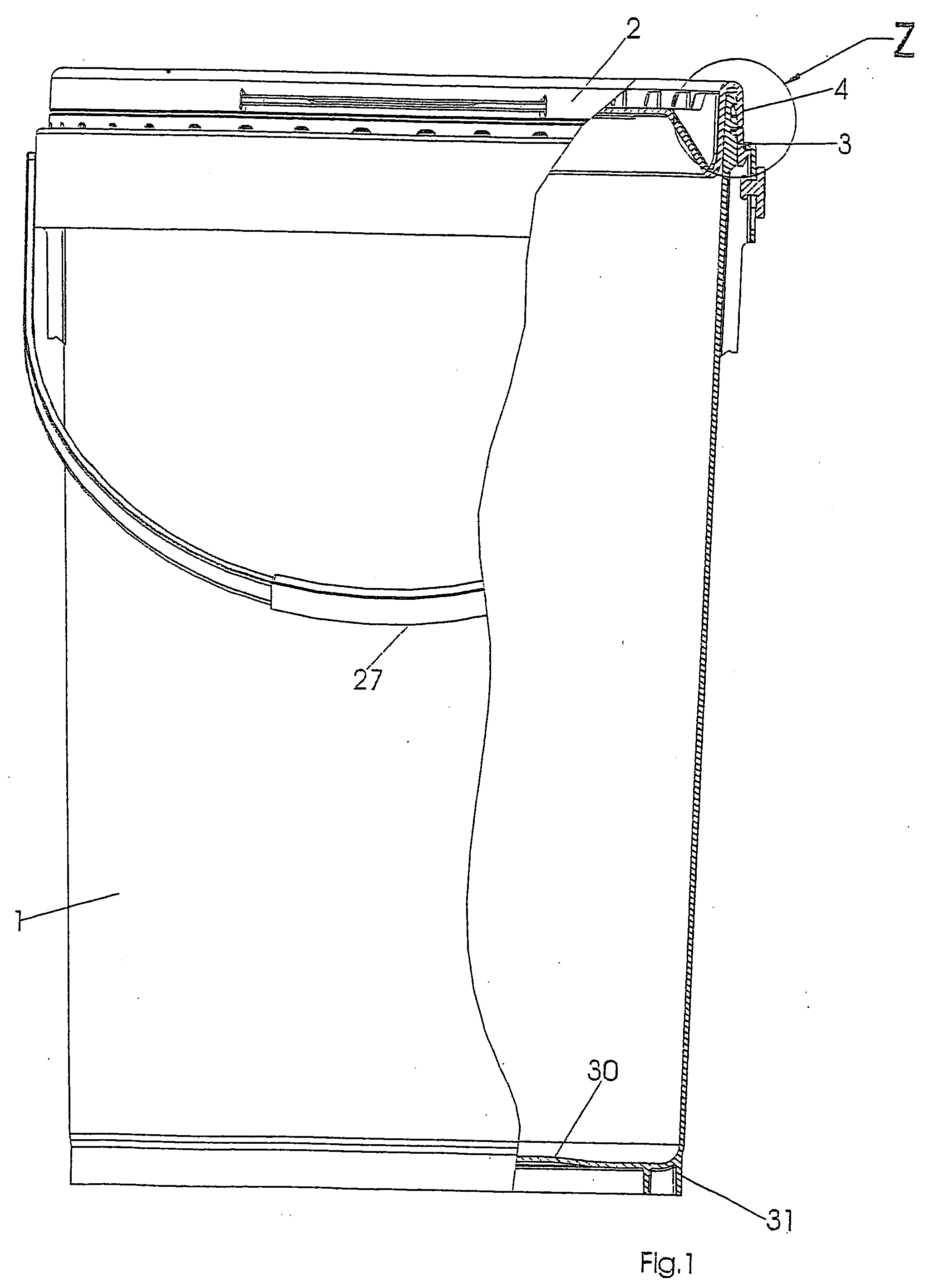

[0036]FIG. 1 shows a partially cut-away side view of a closed container 1 according to the invention, that is, with its lid 2 on. In the embodiment shown, the container 1 is in the form of a pail to which, to facilitate carrying, a rotatable handle 27 is attached.

[0037] As can be seen in the partially cut-away section of FIG. 1, the container 1 has a slightly inward-arching or convex closed bottom 30 that has supporting feet 31 at its outer edge. There is thus a small space between the closed bottom 30 and the surface on which the pail stands. The container 1 furthermore has a slightly conical, albeit essentially cylindrical, outer shape terminating in an open end, so that empty containers can be nested.

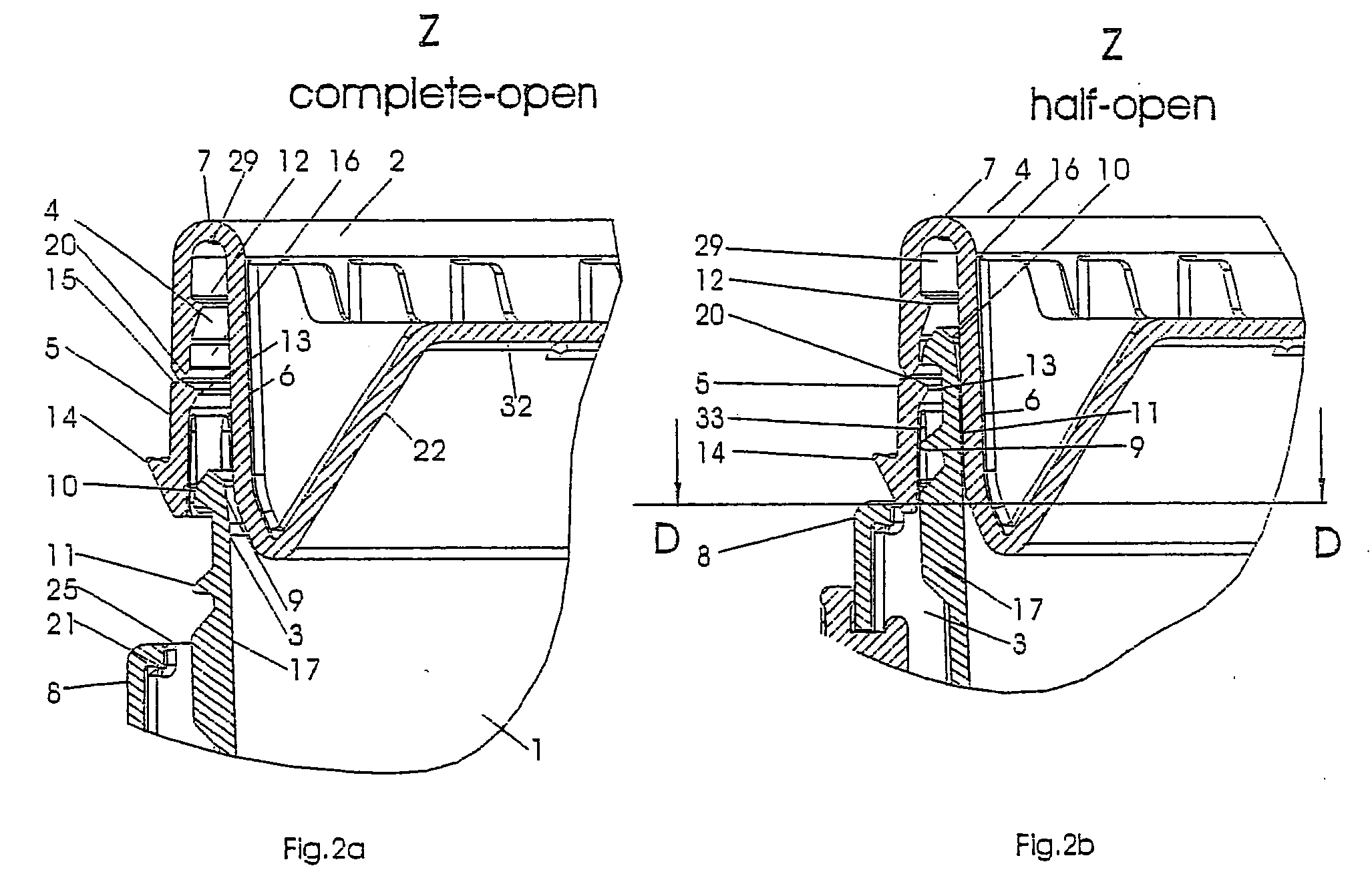

[0038]FIGS. 2a to 2c show details of the upper portion of the cutaway section of FIG. 1, with the receiving area 4 and the lip 3 of the container open end, at various stages of closure of the container 1.

[0039] In FIG. 2a, the container is still completely open. The lid 2 is resti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com