Vehicle for running on rail

a technology for running vehicles and rails, applied in the direction of elevated railways, transportation and packaging, locomotives, etc., can solve the problems of reduced gripping force, easy slippage on rails, and easy slippage, so as to improve the effect of elastic deformation, efficient and smooth running of the vehicle, and moderate gripping for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A vehicle for running on rails of the present invention is explained in detail according to preferred embodiments, referring to the attached drawings.

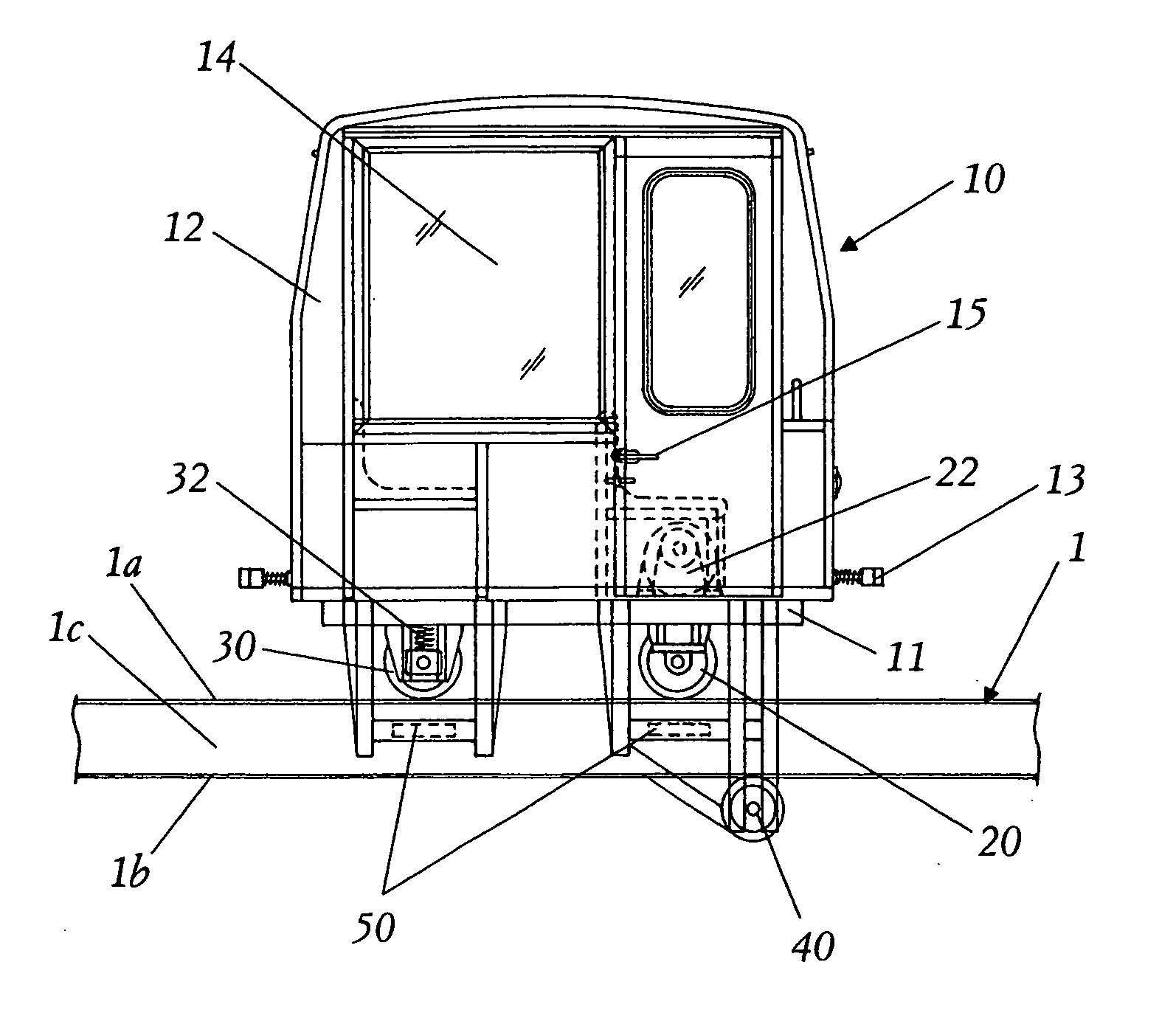

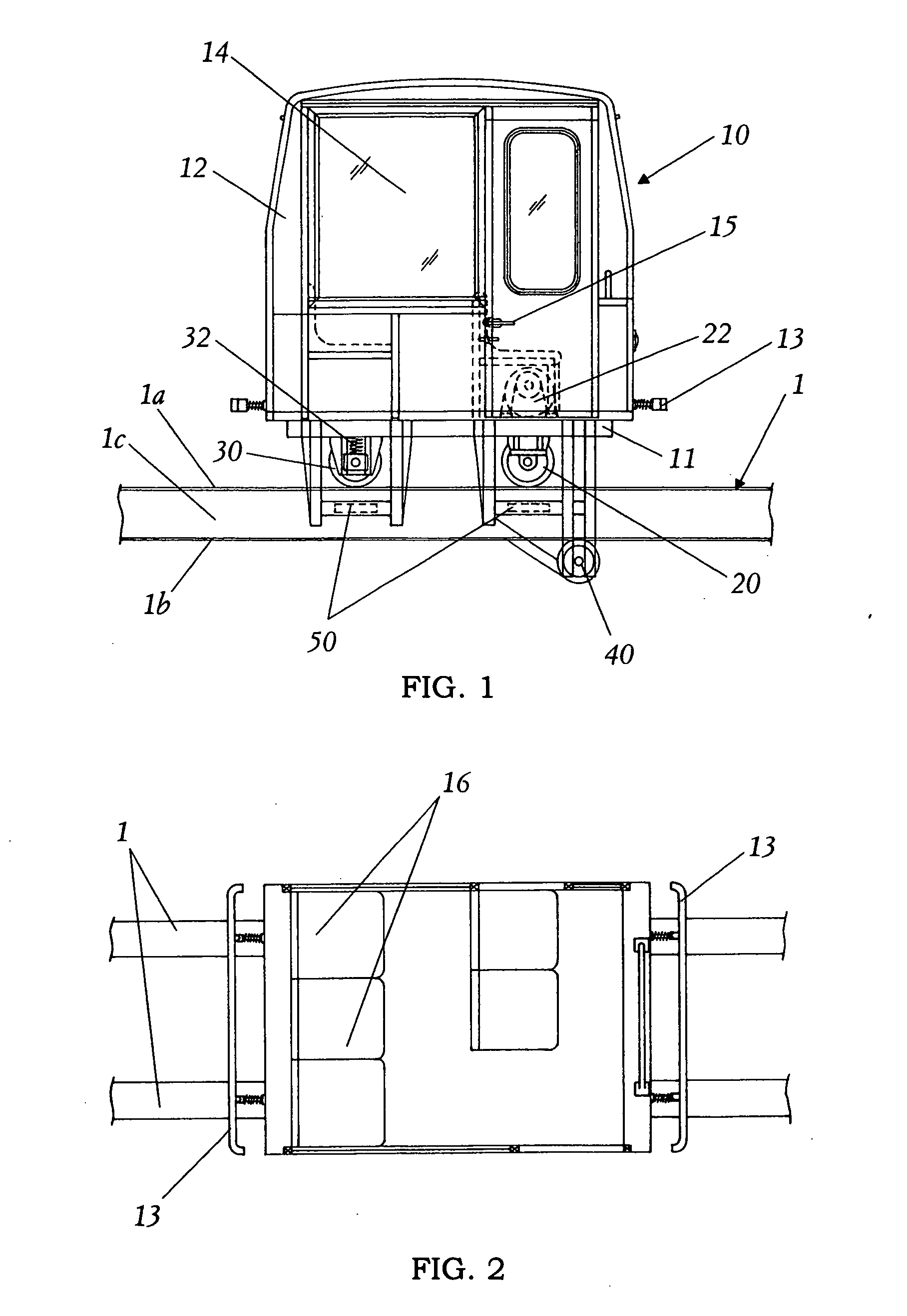

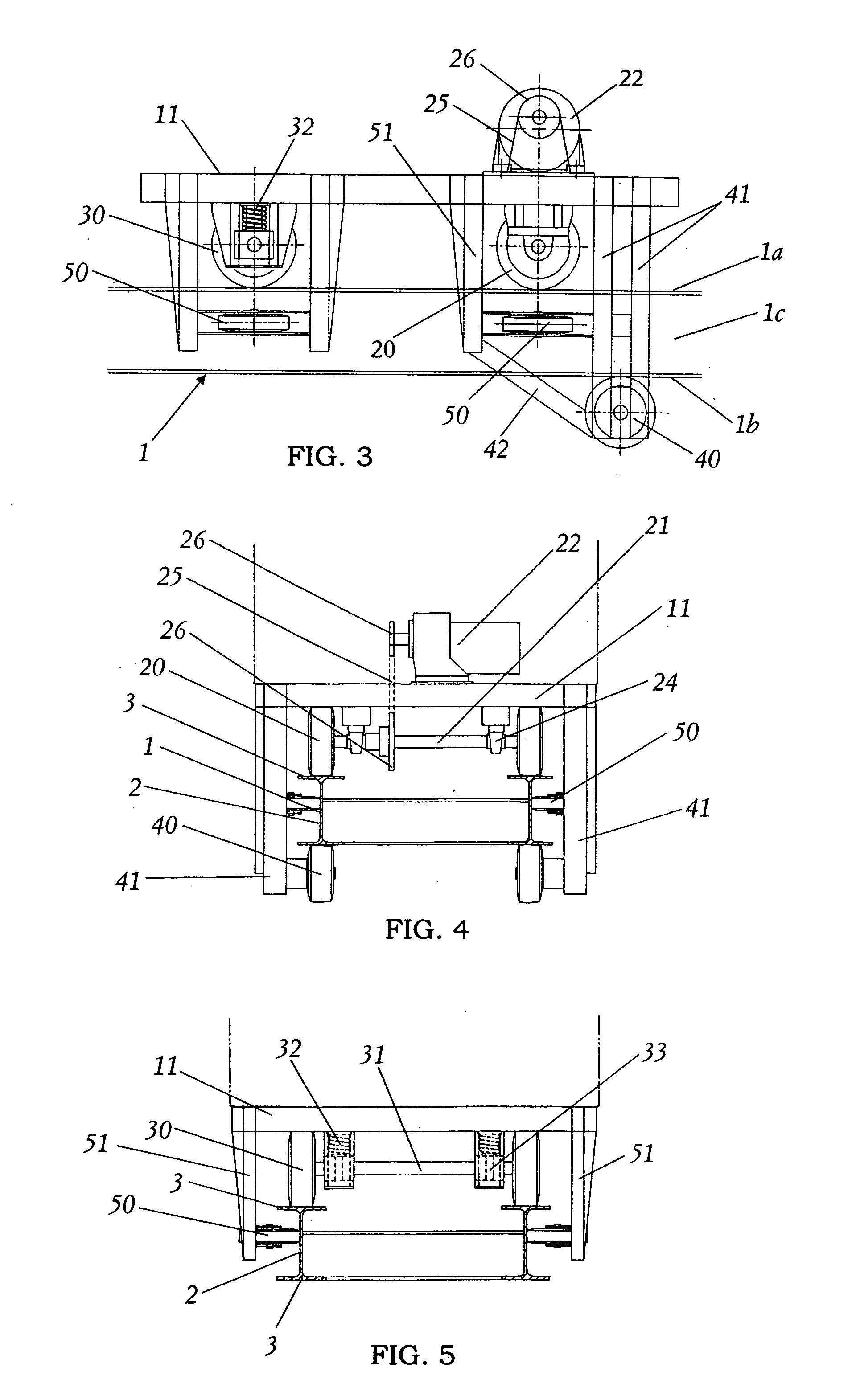

[0025] As shown in FIGS. 1 and 2, the vehicle 10 for running on rails of this embodiment has the capability of running on a pair of rails 1 extending in parallel to each other in the forward and backward directions. The vehicle is formed with a base 11, a body 12 disposed on the base to provide a passenger cabin, a pair of first wheels 20 held by the base to run on upper surfaces 1a of the rails 1, a pair of second wheels 30 held by the base to run on the upper surfaces 1a of the rails 1 and spaced from the first wheels in the extending direction of the rails, a pair of thirds wheels 40 held by the base to run on lower surfaces 1b of the rails 1, four auxiliary wheels 50 held by the base to run on side surfaces 1c of the rails 1 under each of the first and second wheels, and a motor 2 for driving the first wheels 20. As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com