All-terrain high-speed rubber belt track

A rubber crawler, all-terrain technology, applied in the field of rubber belt equipment and all-terrain high-speed rubber crawler, can solve problems such as single adaptability to terrain and environment, restrictions on the movement of construction machinery, and inability to achieve all-terrain walking, etc. The effect of increasing overall strength and toughness, strong grip, and overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

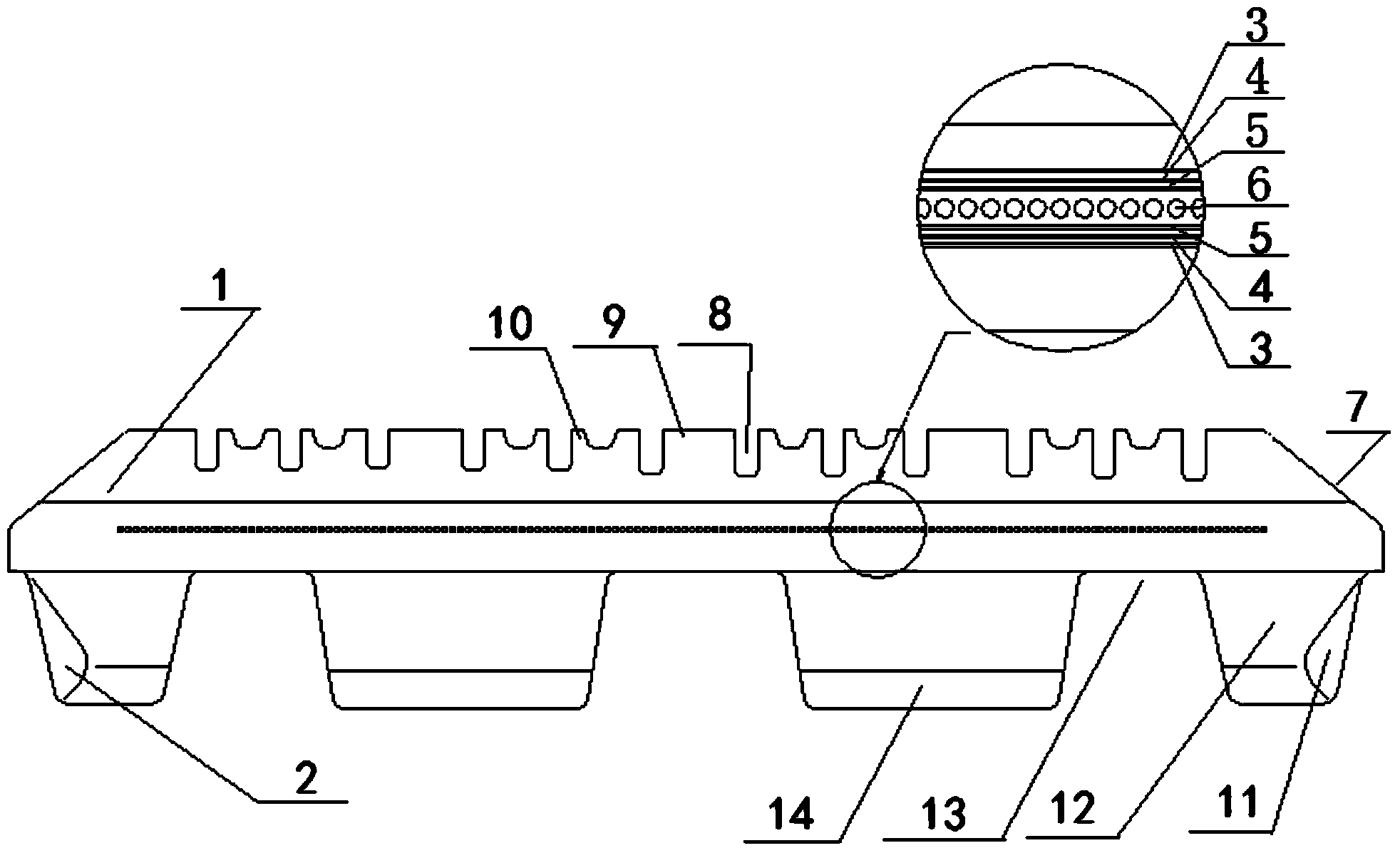

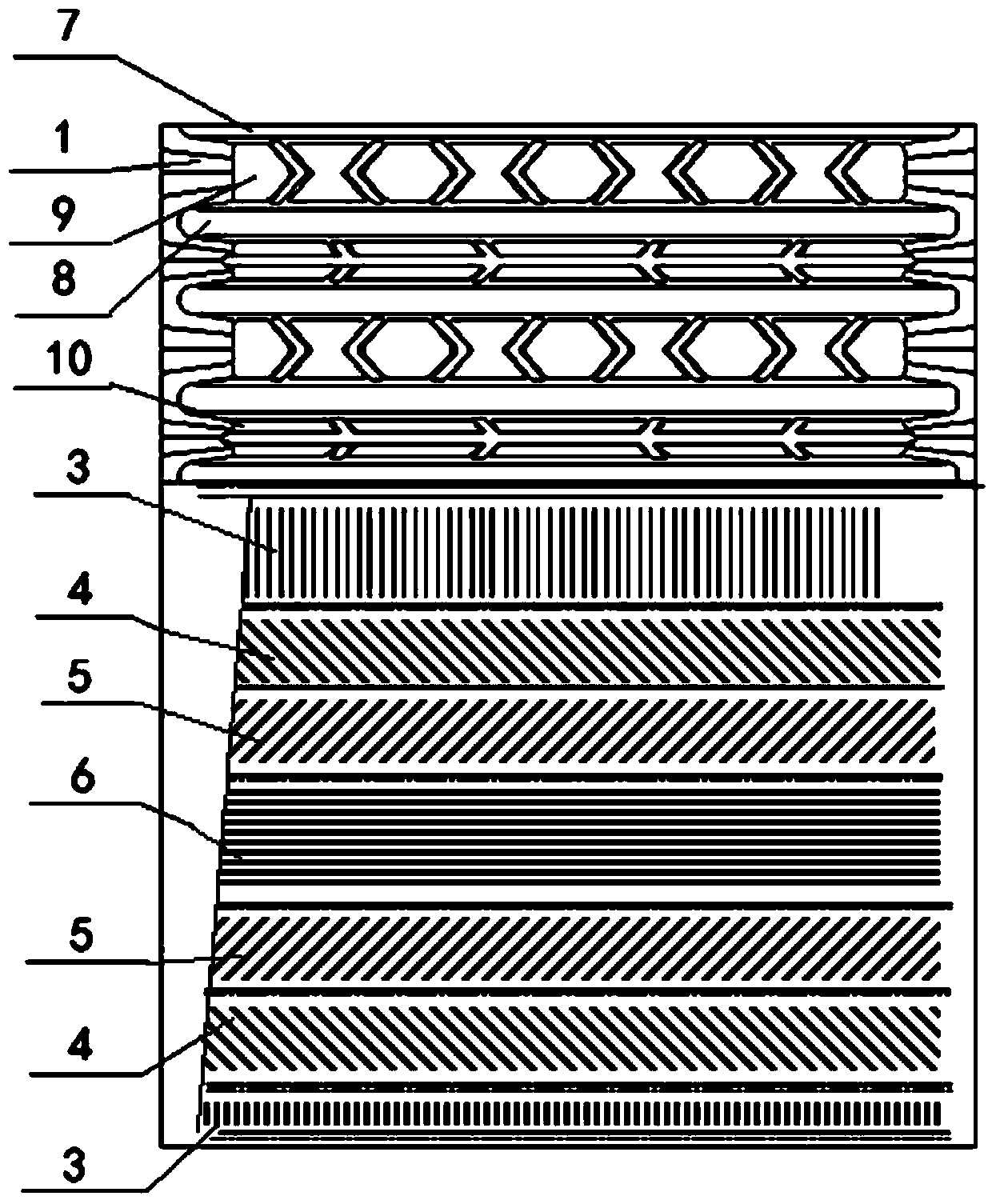

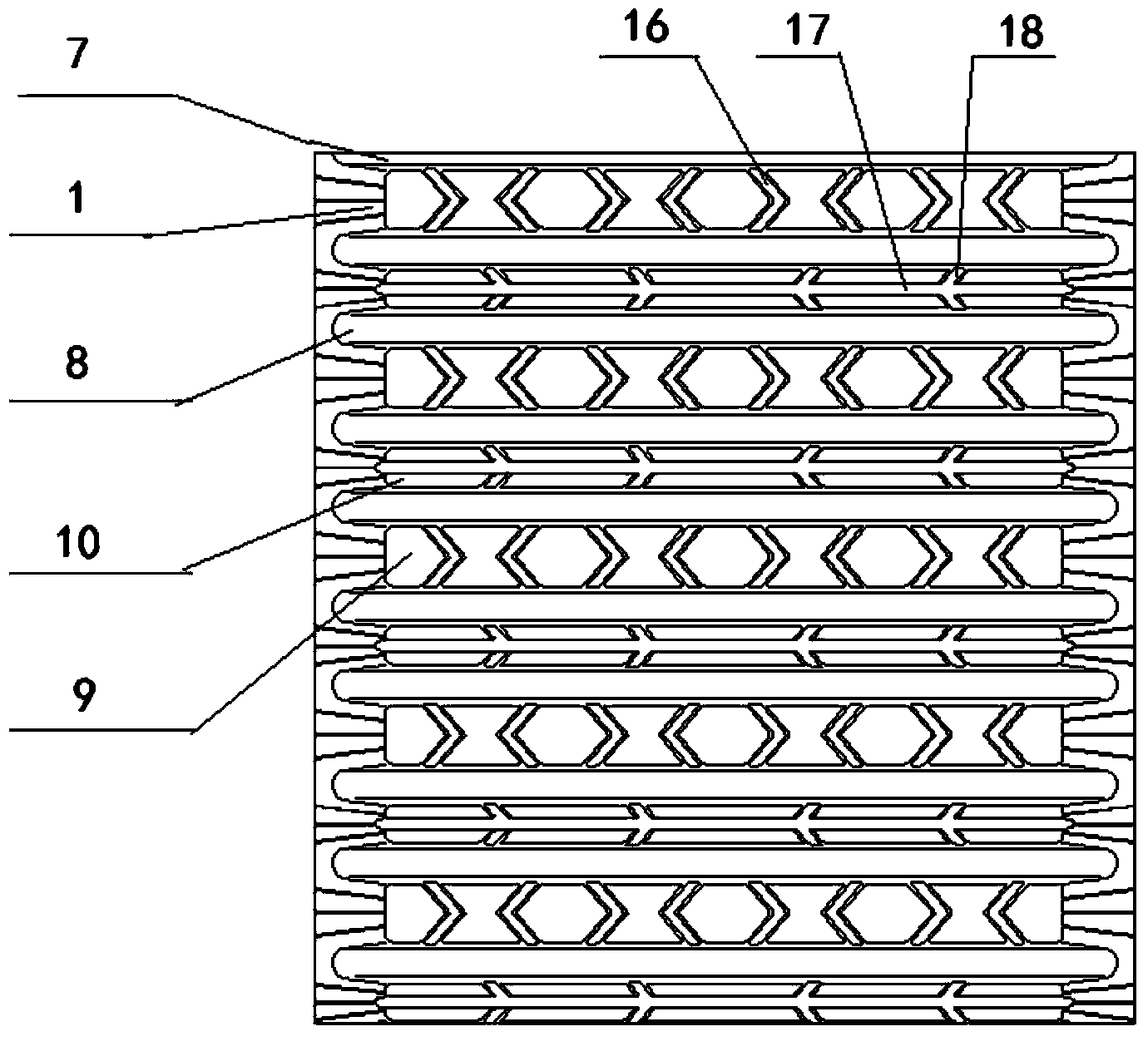

[0030] Embodiment 1: as attached figure 1 As shown, there is a pattern 1 on the outer surface of the track ring, and a guide system 2 on the inner surface, wherein, the support block 9 and the auxiliary block 10 are distributed on the pattern 1 separated by the bottom ring groove 8, and the guide system 2 is guided by the ring direction. The groove 13 and the transverse groove 15 are formed by separating the transverse guide block 14; there is a Kevlar fiber traction layer 6 in the middle circumferential direction inside the crawler belt, and horizontal steel cords 3 and outer steel cords 3 are buried on the upper and lower sides of the Kevlar fiber traction layer 6 respectively. Slanted steel cord 4 and inner inclined steel cord 5.

[0031] In the foregoing, the direction of the Kevlar fiber in the Kevlar fiber traction layer 6 is the same as that of the track ring, the direction of the steel wire in the horizontal steel cord 3 is perpendicular to the track ring direction, an...

Embodiment 2

[0037] Embodiment 2: In Embodiment 1, the inside of the crawler is embedded with a spiral tubular continuous horizontal steel cord 3 or an outwardly inclined steel cord 4 wound outside the Kevlar fiber traction layer 6, that is, the outer surface of the Kevlar fiber traction layer 6 Wrap two layers of inwardly inclined steel cords 5 or inwardly inclined steel cords 5 with opposite helical directions.

[0038] In the present invention, the traditional iron teeth are not used as the transmission bearing parts, but through the improvement of the track guide system, pure rubber is used as the guide block to control the drive of the track, which reduces the overall weight of the track. In addition, the traction parts of the strength layer do not use stainless steel wires, but high-strength Kevlar fibers are used. On the upper and lower sides of the Kevlar fibers, there are two layers of steel cords crossing each other to control the overall strength of the track. And toughness, on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com