Torque transducer assembly

a technology of torque transducer and assembly, which is applied in the direction of force sensors, rotating screw stopper insertion, cap, etc., can solve the problems of high cost, time-consuming, difficult to measure the amount of capping torque applied by a capping system, etc., and achieves a relatively inexpensive solution, simple, quick and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

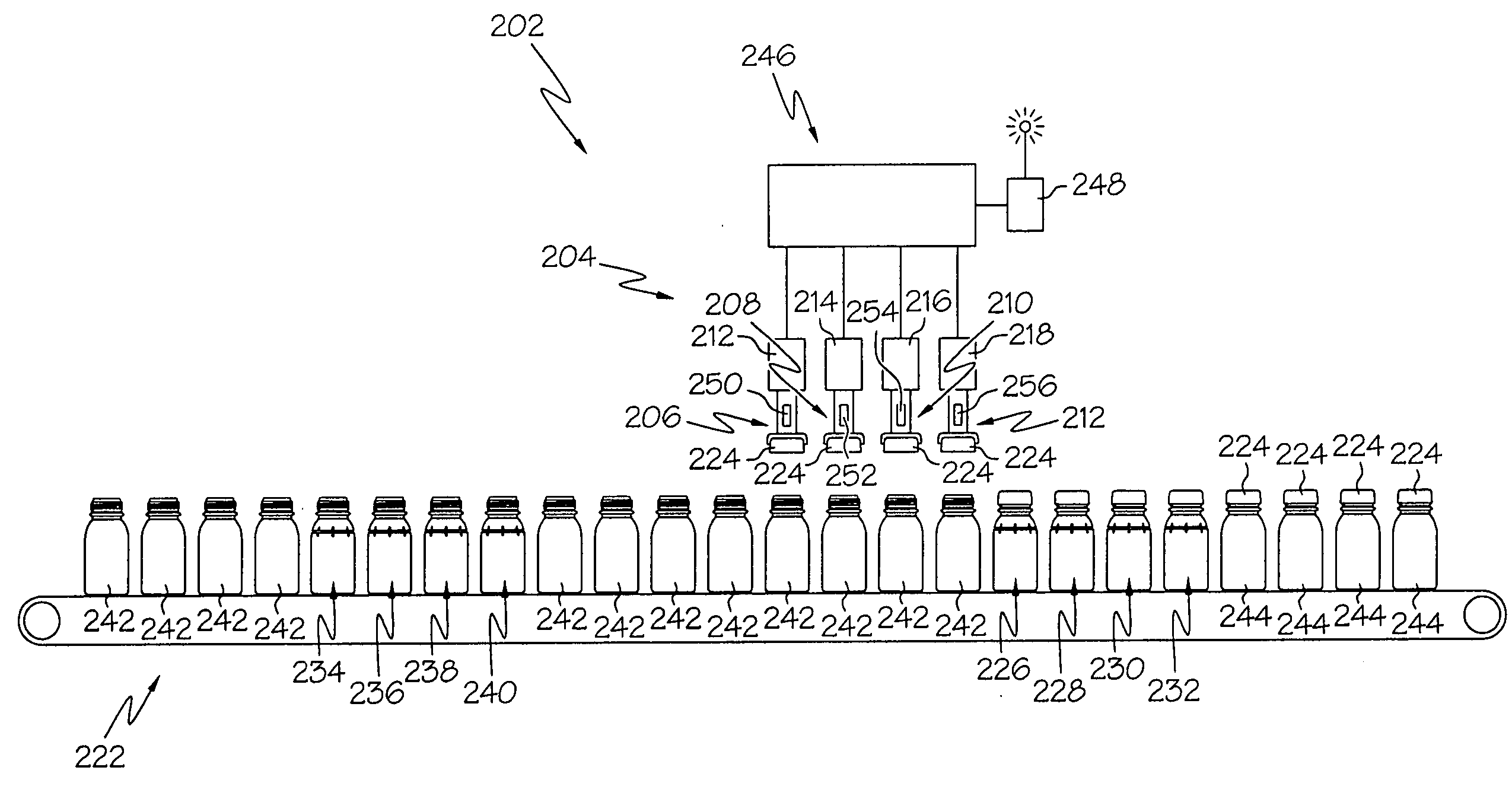

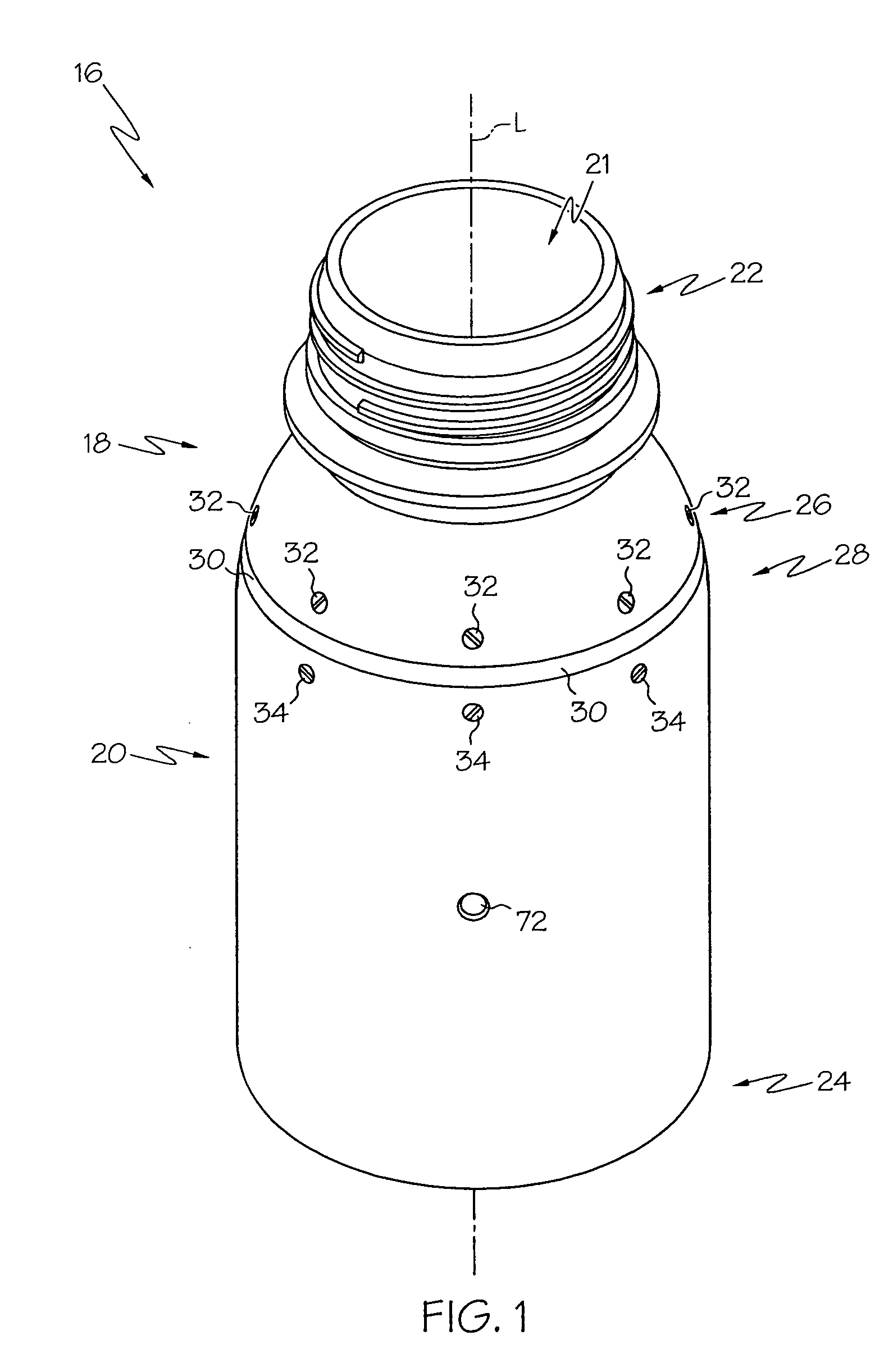

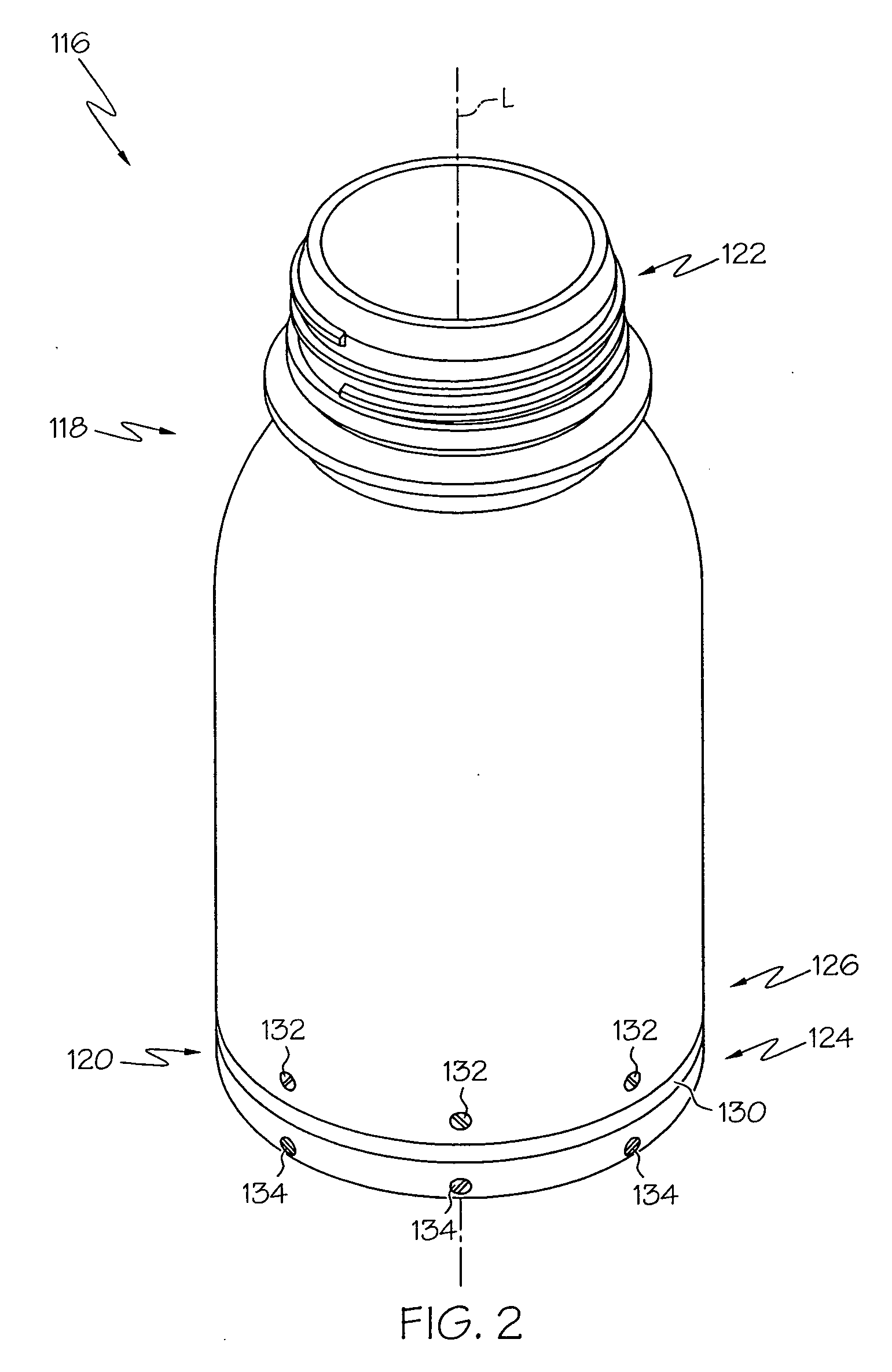

[0028] The present invention and its operation is hereinafter described in detail in connection with the views and examples of FIGS. 1-16, wherein like numbers indicate the same or corresponding elements throughout the views. These embodiments are shown and described only for purposes of illustrating examples of elements of the invention, and should not be considered as limiting on alternative structures or assemblies that will be apparent to those of ordinary skill in the art. Referring to FIG. 1, a torque transducer assembly 16 is depicted. The torque transducer assembly 16 can have an external configuration that is sufficiently similar to that of an ordinary container such that the torque transducer assembly 16 can be capped along with normal containers (e.g., as shown and discussed later with respect to FIG. 9) without substantially interfering with the capping process (i.e., the torque transducer assembly can have a size and shape that won't jamb the conveyor and / or capping sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com