Braking assembly for a roller skate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

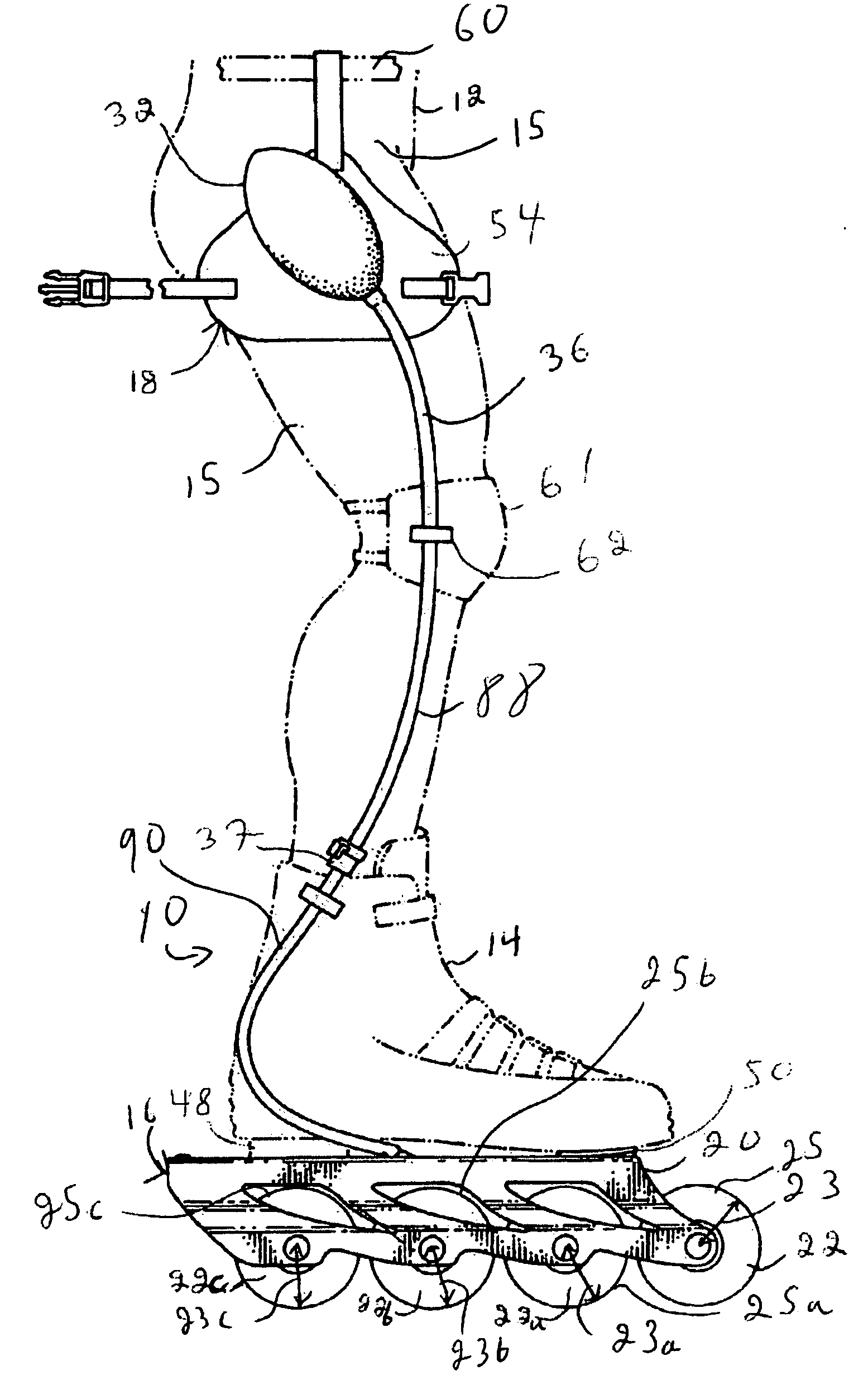

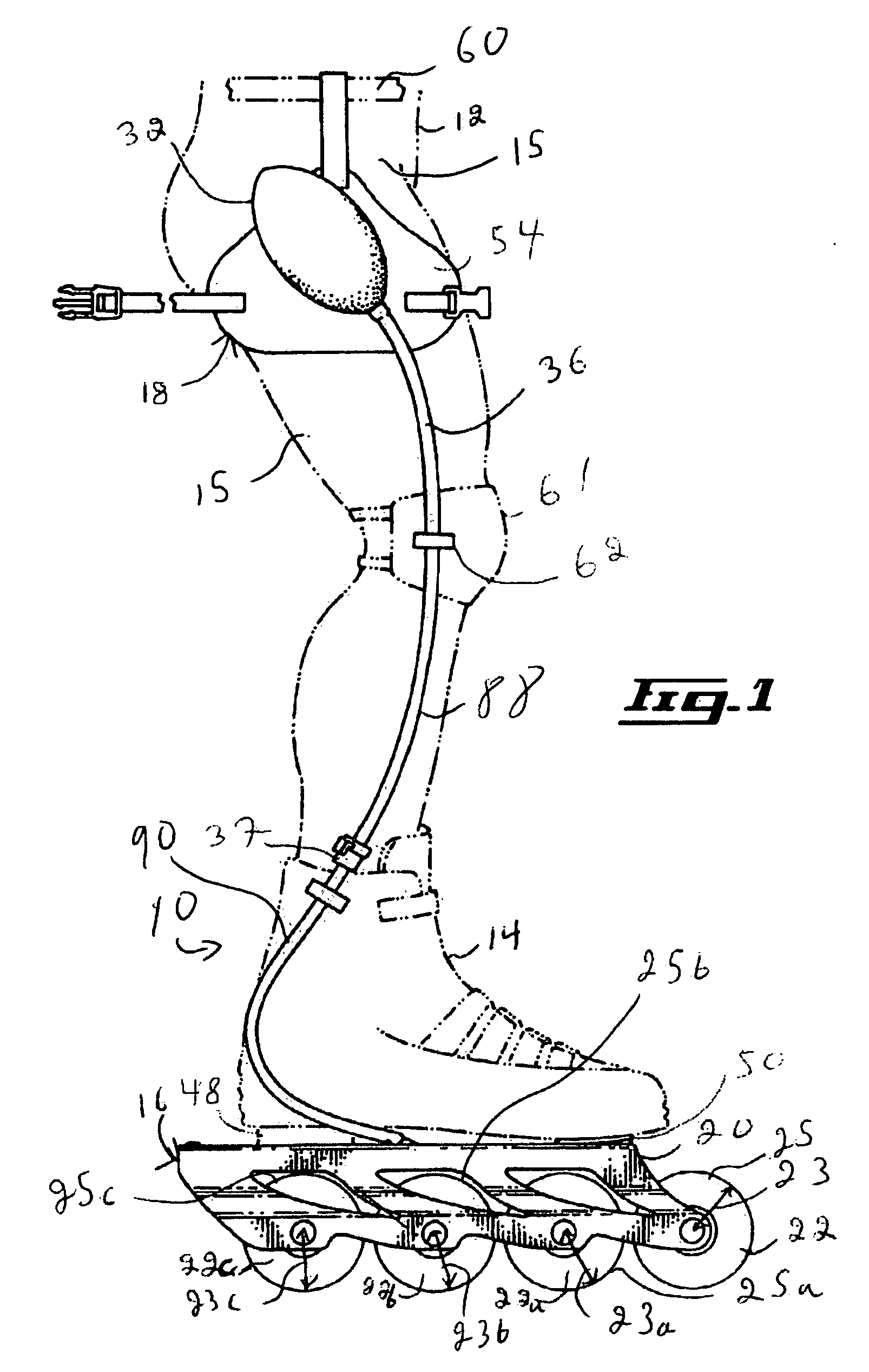

[0034]FIG. 1 illustrates a roller skate 10 for use by an intended user 12, only the leg 13 and waist 15 thereof being shown in the drawings. The intended user 12 has a foot (not shown in the drawings) and uses the roller skate 10 onto a surface (both not shown in the drawings).

[0035] The roller skate 10 includes a foot receiving portion in the form of a skate boot 14 for receiving the foot of the user 12. The roller skate 10 further includes a roller assembly 16 coupled to the skate boot 14. Furthermore, the skate 10 includes a braking assembly 18 operatively coupled to the roller assembly 16 so as to be able to modulate the speed of the intended user 12 when he uses the roller skate 10.

[0036] The skate boot 14 is any suitable skate boot. Such skate boots are well known in the art and the skate boot 14 will therefore not be described in further details. Also, in alternative embodiments of the invention, the skate 10 includes any other suitable foot receiving portion.

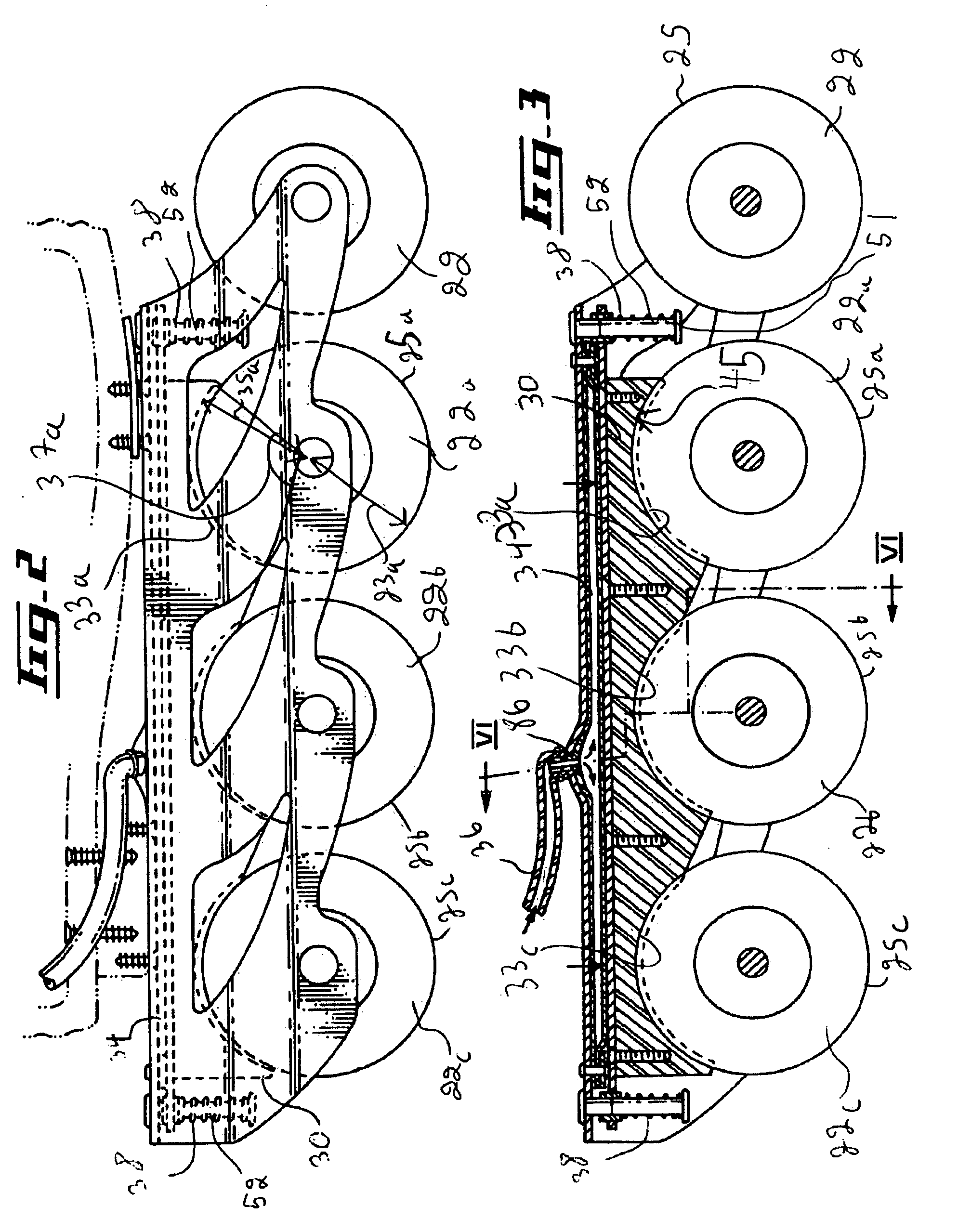

[0037] The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com