Partition wall

a technology of partition wall and wall element, applied in the field of partition wall, can solve the problems of inability to change the embodiment of unalterable embodiment, inability to use variablely, and only in a limited extent, and achieve the effect of wide-ranging flexibility and variability of the partition wall, and enhanced sound absorption property of the wall elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

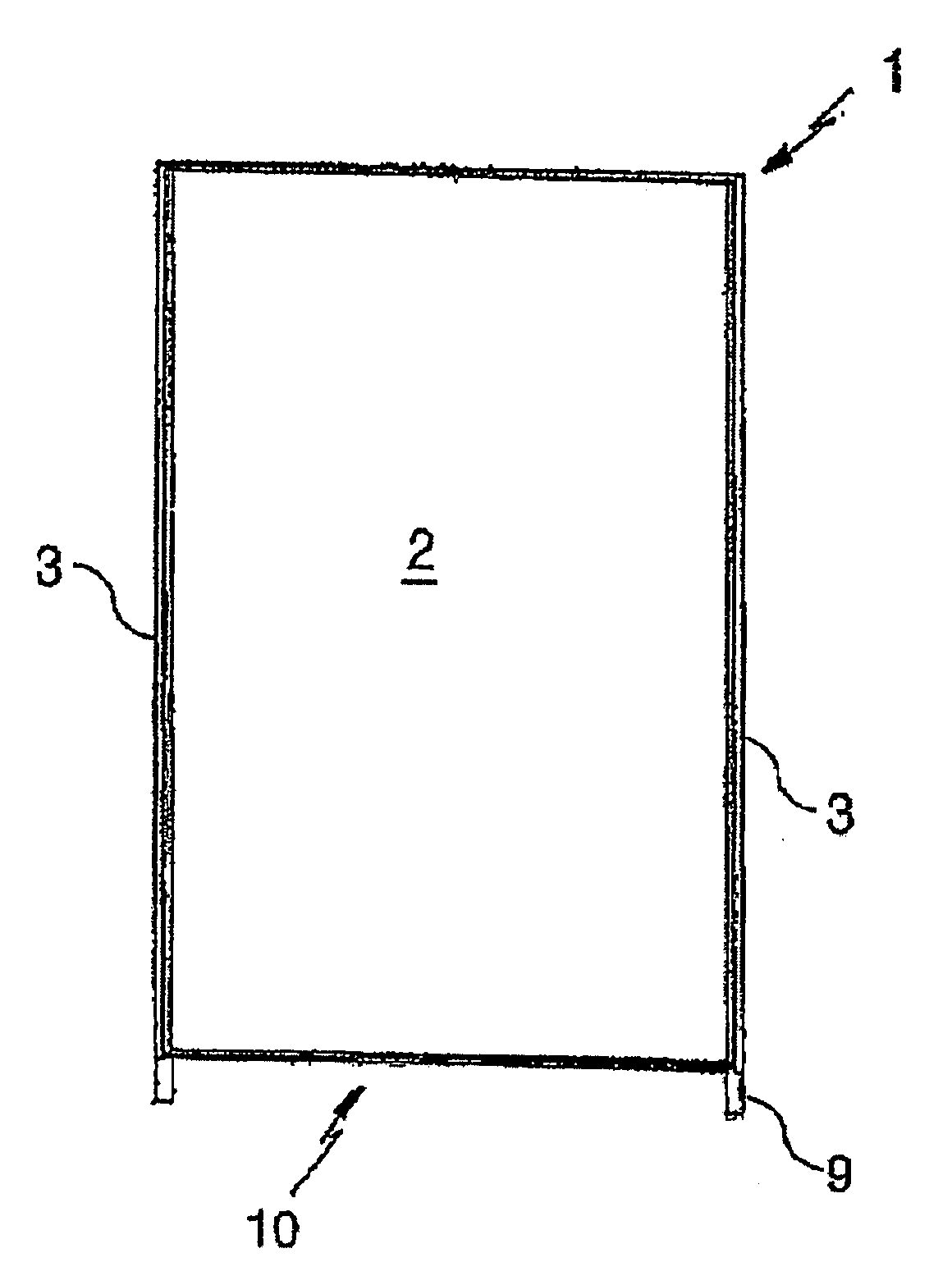

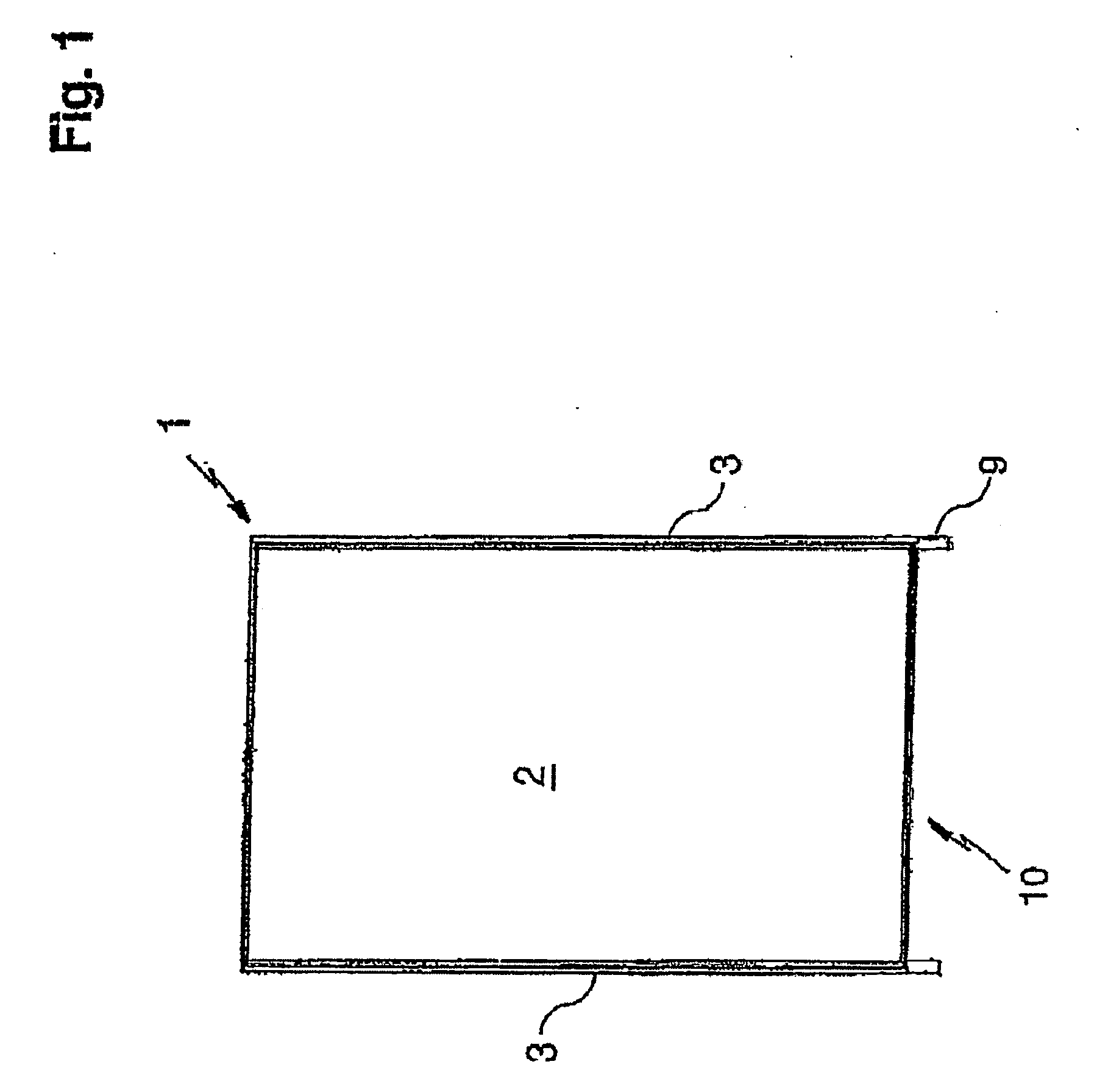

[0029]FIG. 1 shows a partition wall according to the invention in the form of a single wall element 1, it being understood that several wall elements 1 can be connected to one another to form the partition wall. The wall element 1 comprises a wall panel 2 and frame parts enclosing the wall panel 2 to form a frame 3.

[0030] According to the invention, on at least on one side of the wall element 1 the wall panel 2 can be inserted into the frame 3 and correspondingly exchanged.

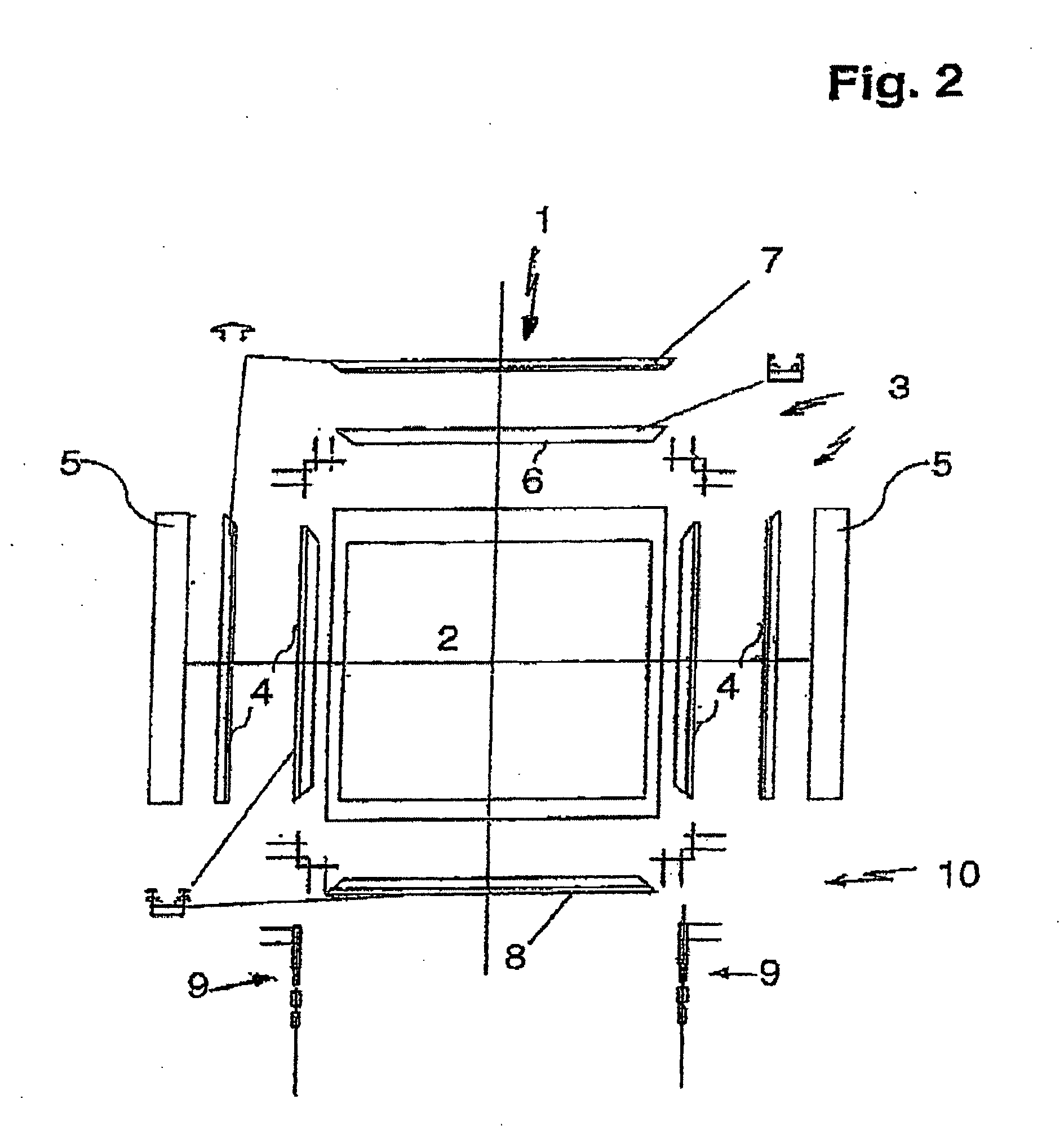

[0031]FIG. 2 shows the wall element 1 in an exploded representation, namely along with the wall panel 2 the respective frame parts and covers, i. e. the lateral frame parts 4 together with the lateral covers 5, the upper frame part 6 with the upper cover 7, and the lower frame part 8 which with the supporting feet 9 forms the base 10. The frame parts 4, 6, and 8 are made in the form of aluminum profiles. The covers 5 and 7 are also aluminum parts, where any materials can be used here.

[0032]FIG. 3 shows in two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com