Fairway wood with titanium face member

a titanium face member and fairway wood technology, applied in the field of fairway woods and fairway woods having a head, can solve the problems of affecting the overall springiness of the faceplate, the effect of shooting to hook or slice, and partial loss of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

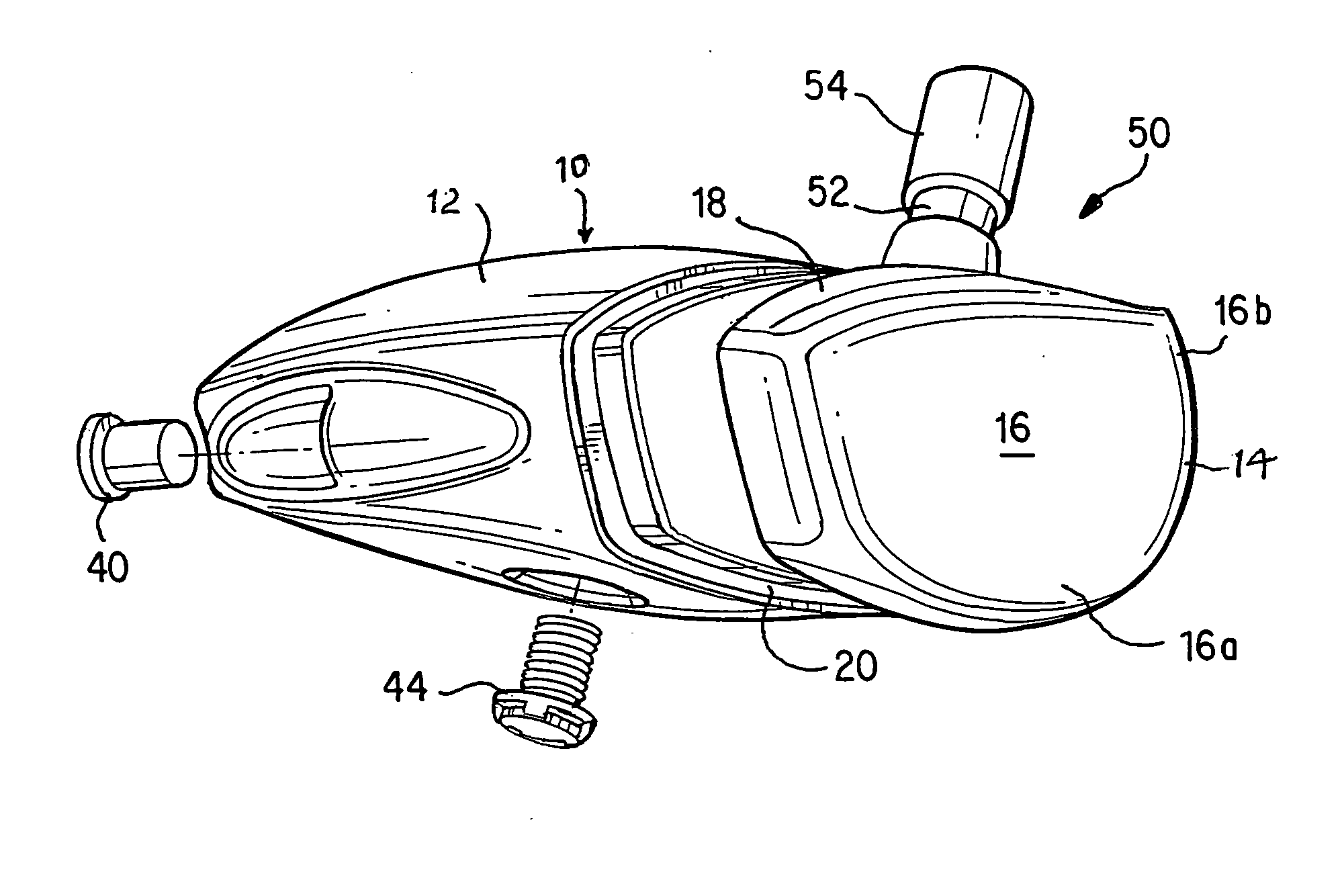

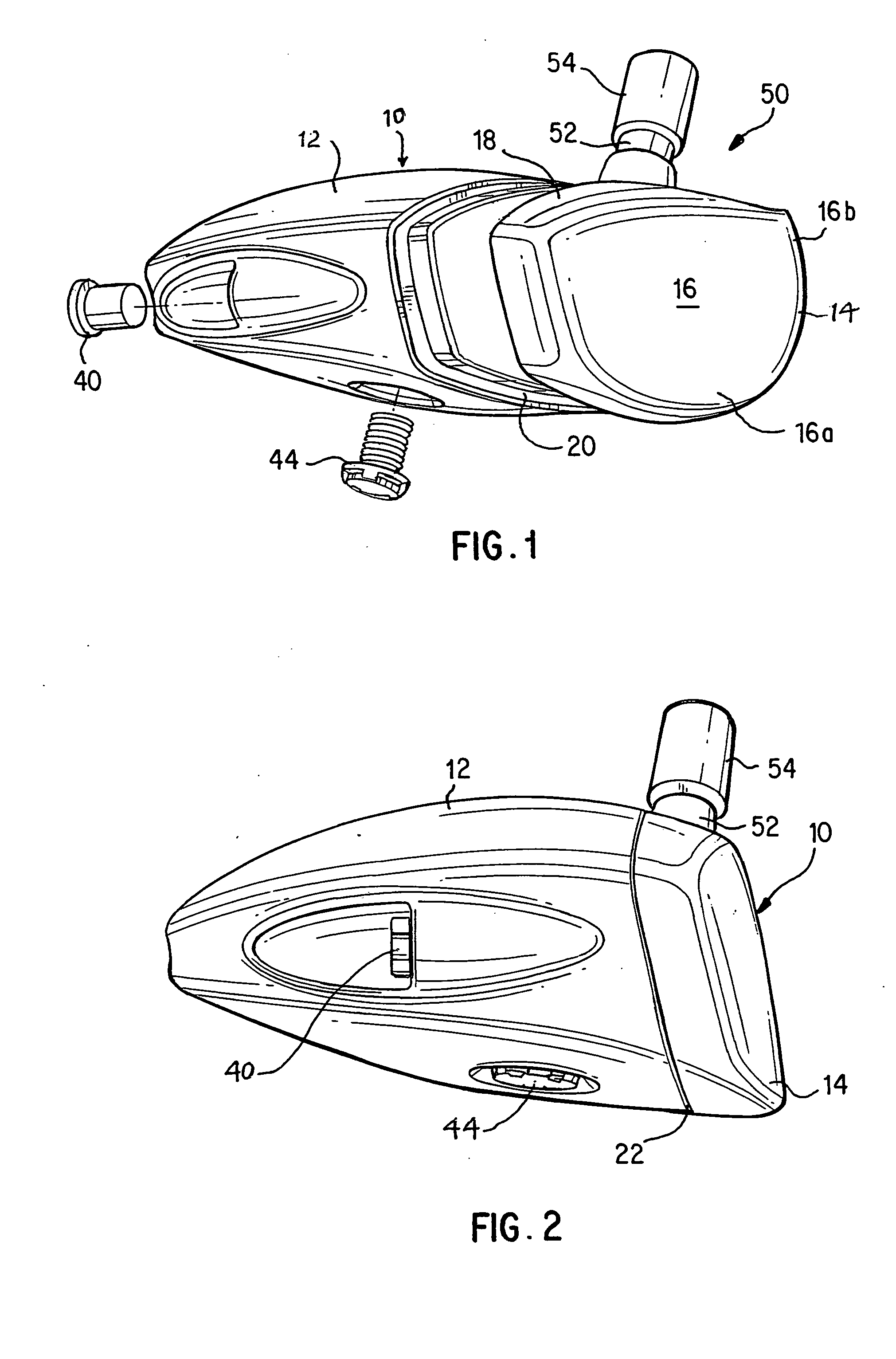

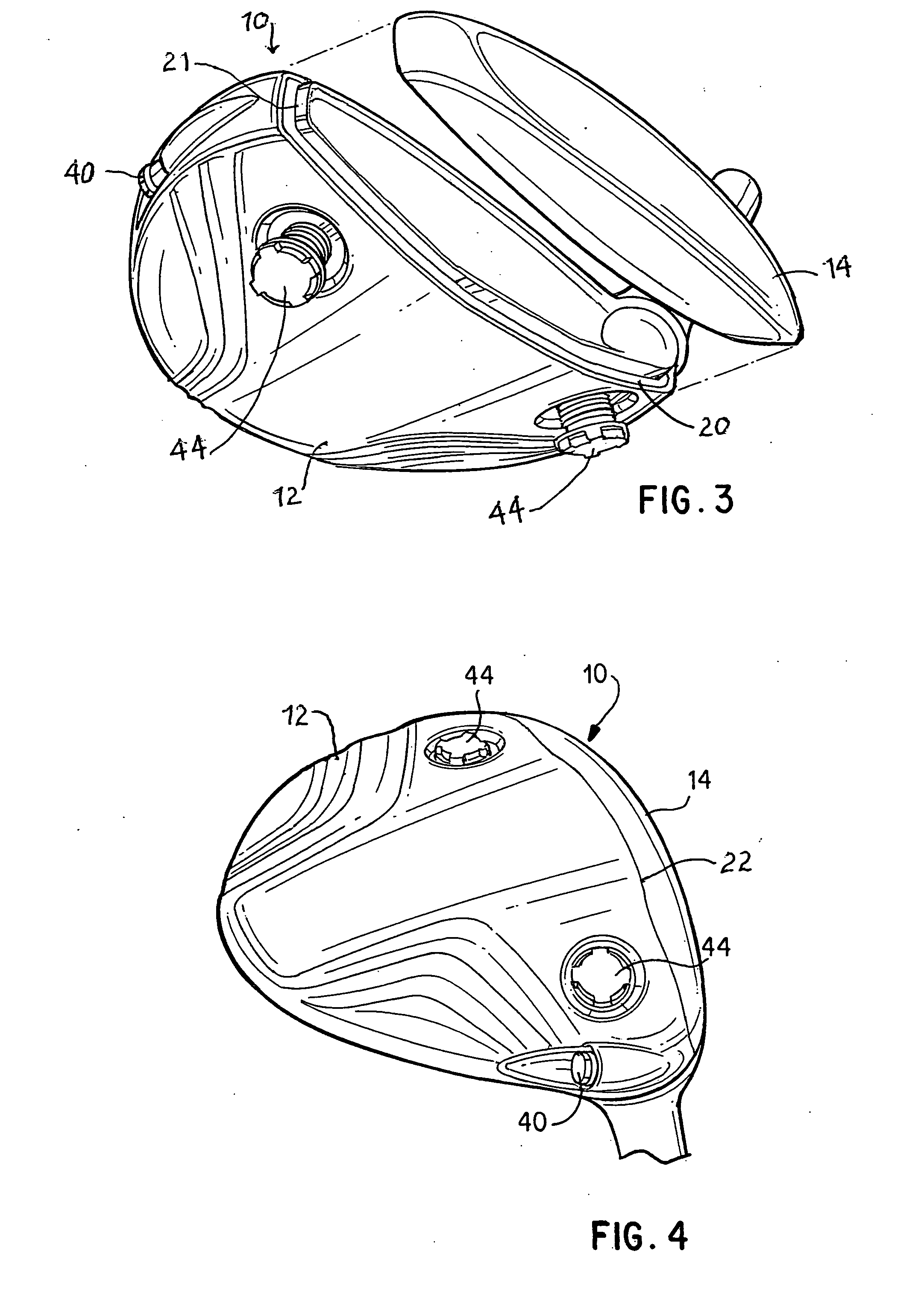

[0032] Depicted in FIGS. 1-6 is a head 10 of a fairway wood comprising a stainless steel body 12, and a titanium alloy face member 14 attached to a front side thereof. The face member 14 is cup-shaped in that it comprises a front portion 16 and a rim or lip 18 projecting rearwardly from an outer periphery of the front portion. A rearwardly-facing rear edge 18a of the rim 18 (see FIG. 10) is bonded by silver-nickel brazing 22 to a forwardly-facing seat 20 of the body 12. The seat 20 is bordered inwardly by a forwardly-projecting ridge 21 of the body which extends endlessly around the seat 20.

[0033] The shapes of the seat and the mating surface of the rim can vary. For example, the forwardly facing seat of the body could comprise a forwardly open recess 20′ disposed between two endless ridges 21′, 21″ of the body as shown in FIG. 3a. The rear edge of the rim 18 would include a rearwardly projecting rib 22′ that fits into the recess 21′. As in the case of FIGS. 1-6, the rear edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com