Fixing device comprising a rotary drive for a gripper tool

a technology of fixing device and gripper tool, which is applied in the direction of mechanical machines/dredgers, load-engaging elements, soil shifting machines/dredgers, etc., can solve the problem that the impact cannot be passed on to the shaft of the hydromotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

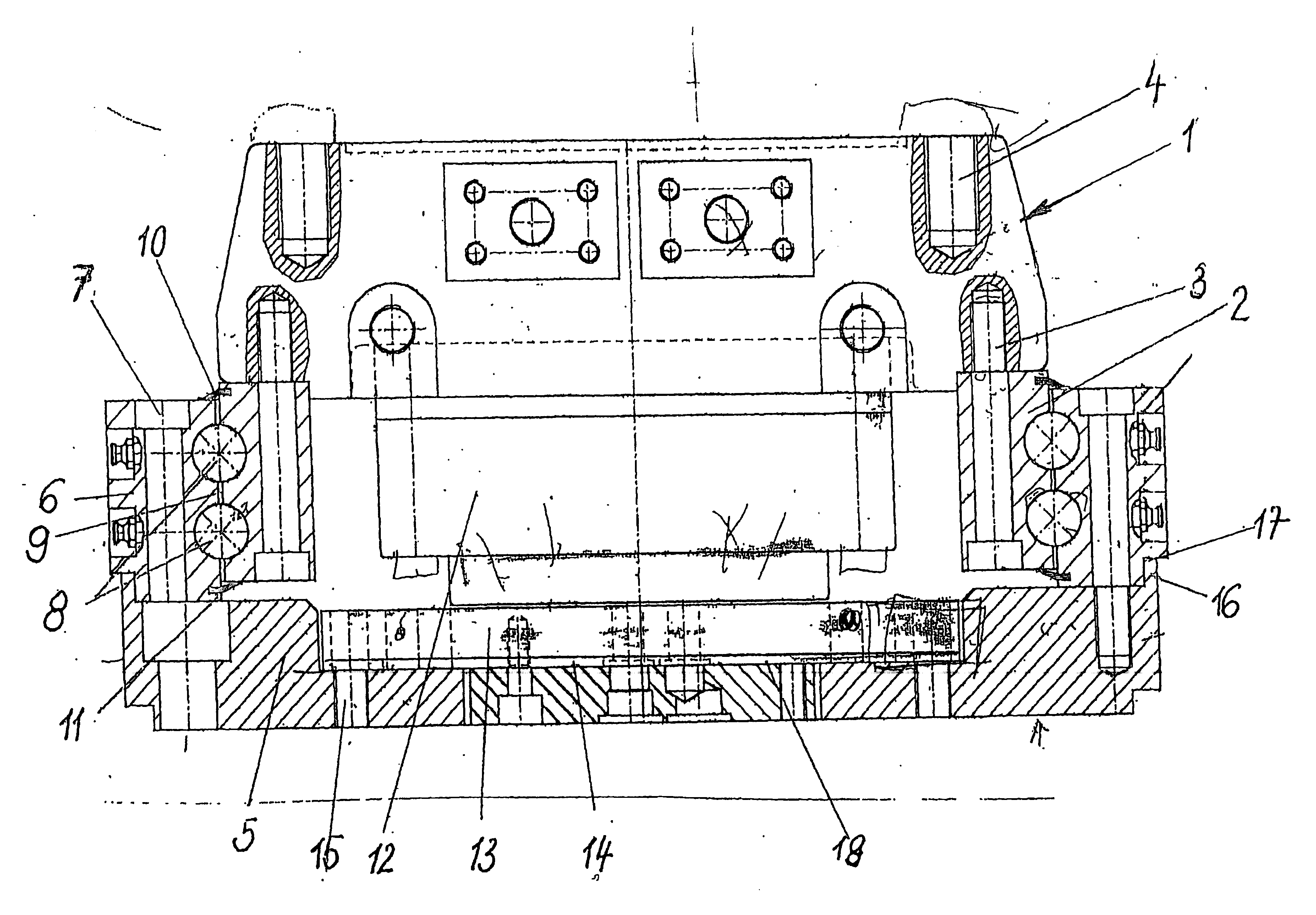

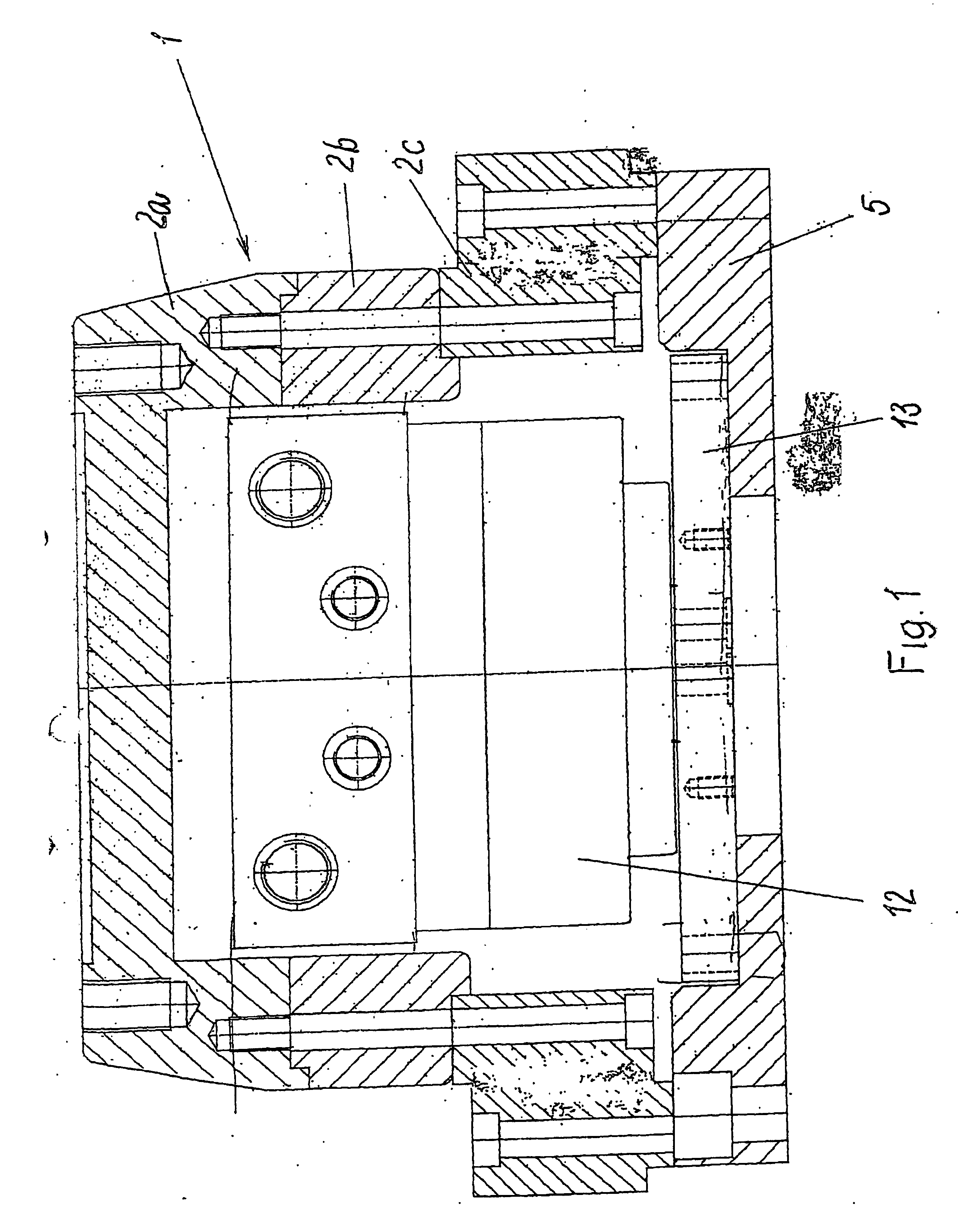

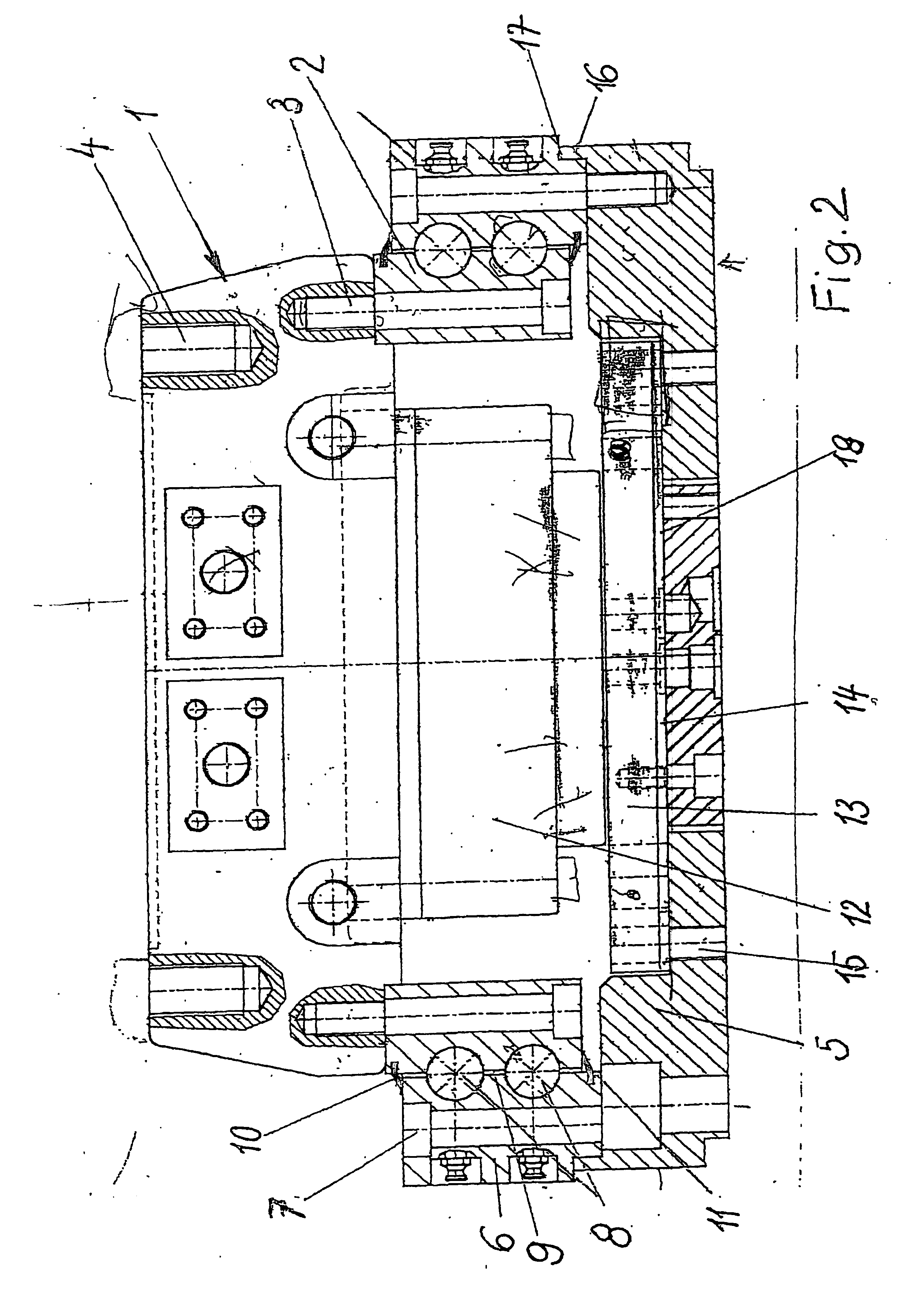

[0017] As has already been stated in the foregoing, a device for attaching and for rotary drive of a gripping tool or the like has a housing 1 that is constructed from the annular housing parts 2a, 2b, and 2c. These housing parts are securely bolted to one another. A hydromotor 12 is inserted rotation-fast in the housing and attached using means that are not shown. The hydromotor drives a driven flange 13 that itself is bolted to an adapter plate 5. In this device known from the prior art the driven flange 13 and the adapter plate 5 are flush against one another. However, depending on installation tolerances, the adapter plate 5 can also be in contact with the end face of the housing part 2.

[0018] This device is attached by means of the housing part 2a to the boom of a crane, excavator, or similar conveying and lifting machine. Thus, the adapter plate 5 carries the gripping tool and causes it to move rotationally for working as soon as the hydromotor 12 is actuated.

[0019] The know...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com