High performance low cost driver using multiple material face design

a face design and driver technology, applied in the field of golf clubs, can solve the problems of increased energy transfer problems, increased deformation of golf balls, energy loss, etc., and achieve the effect of increasing the post-impact velocity of golf balls and high coefficient of restitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

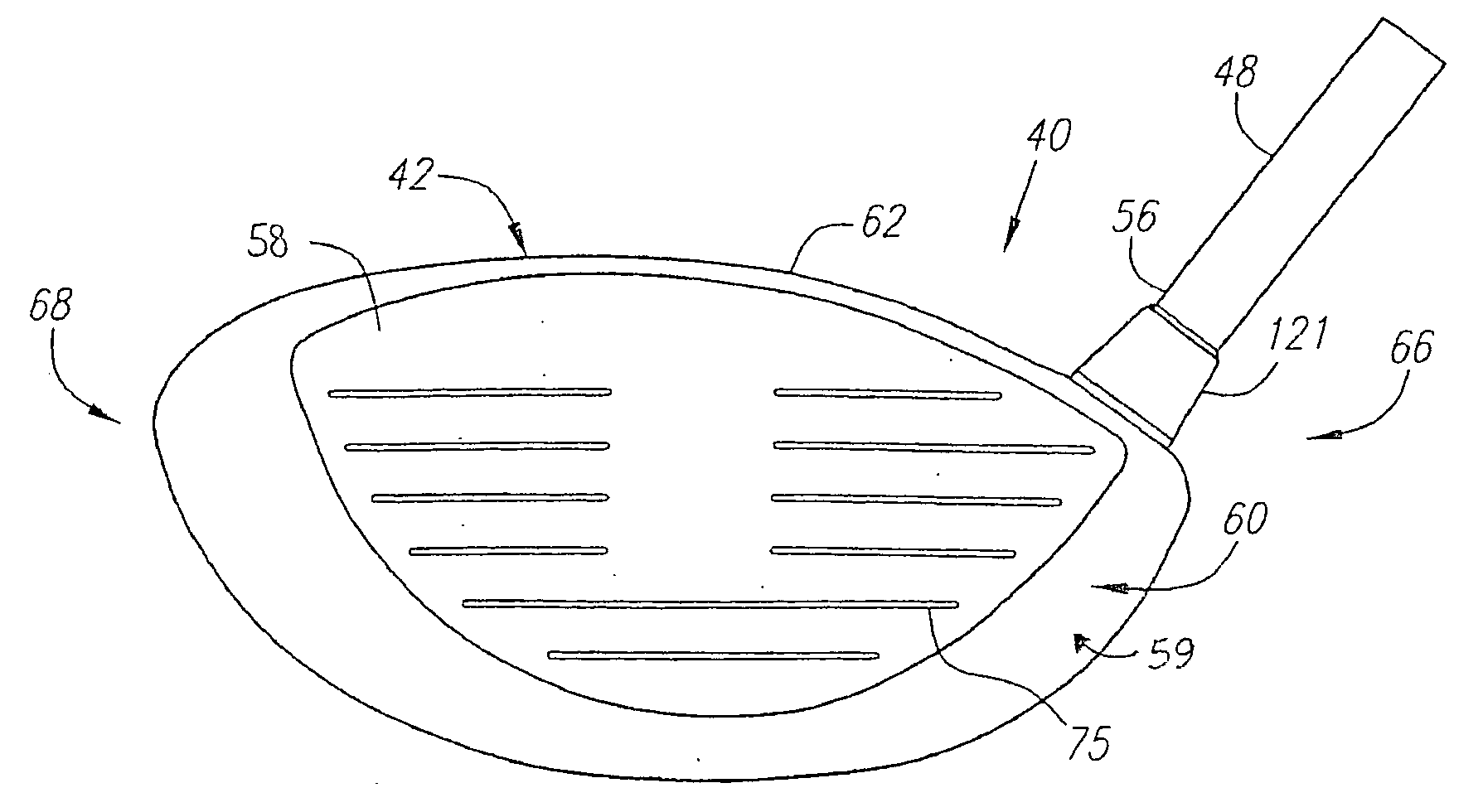

[0055] As shown in FIG. 1, a golf club is generally designated 40. The golf club 40 has a golf club head 42. When designed as a driver, the club head 42 preferably has a volume from 200 cubic centimeters to 600 cubic centimeters, more preferably from 300 cubic centimeters to 500 cubic centimeters, and most preferably from 350 cubic centimeters to 480 cubic centimeters. The volume of the golf club head 42 will also vary between fairway woods (preferably ranging from 3-woods to eleven woods) with smaller volumes than drivers. The golf club head 42 preferably has a mass no more than 225 grams, and most preferably a mass of 180 grams to 215 grams. Engaging the club head 42 is a shaft 48 that has a grip, not shown, at a butt end and is inserted into a hosel 54 (FIG. 13A) at a tip end 56.

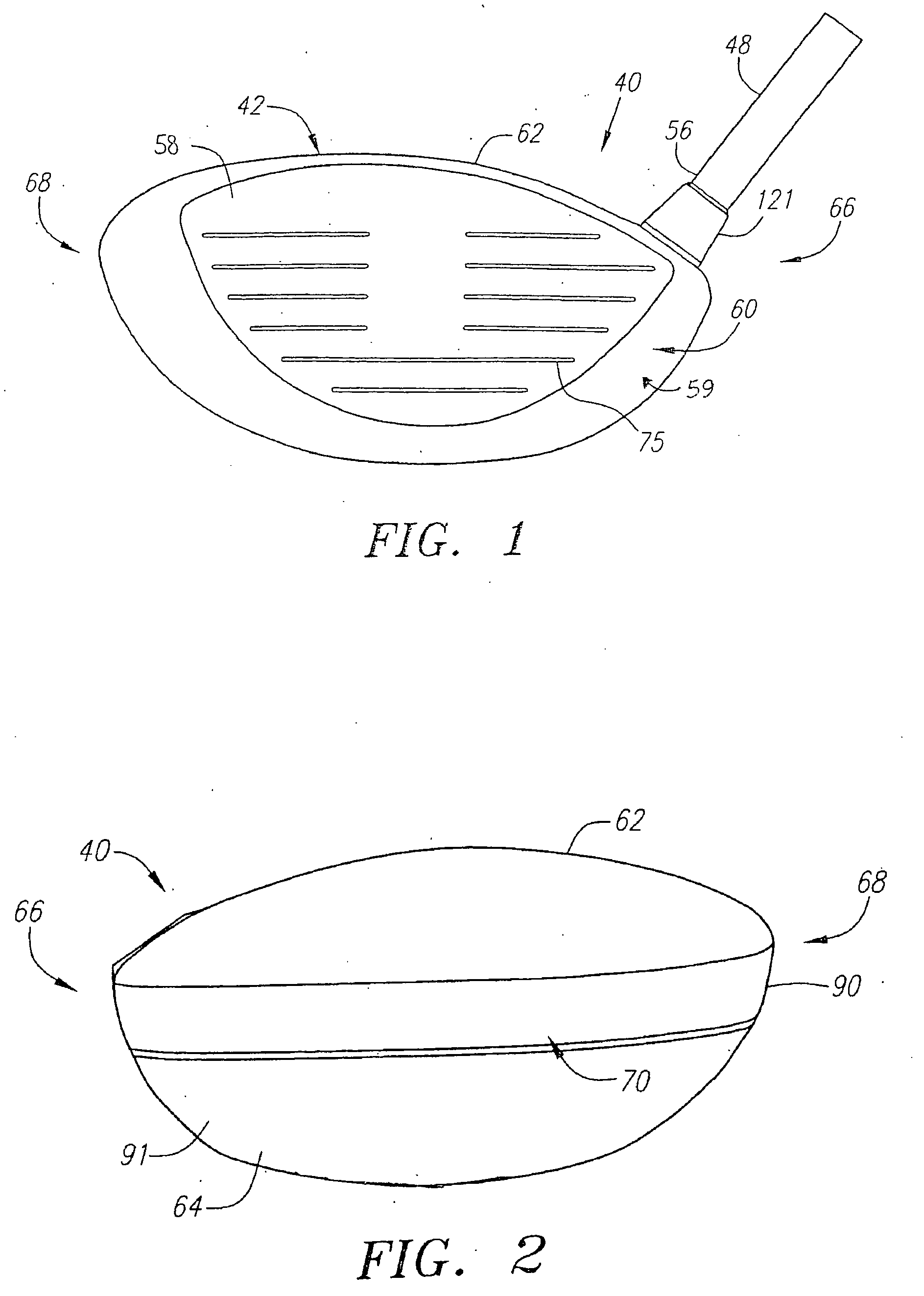

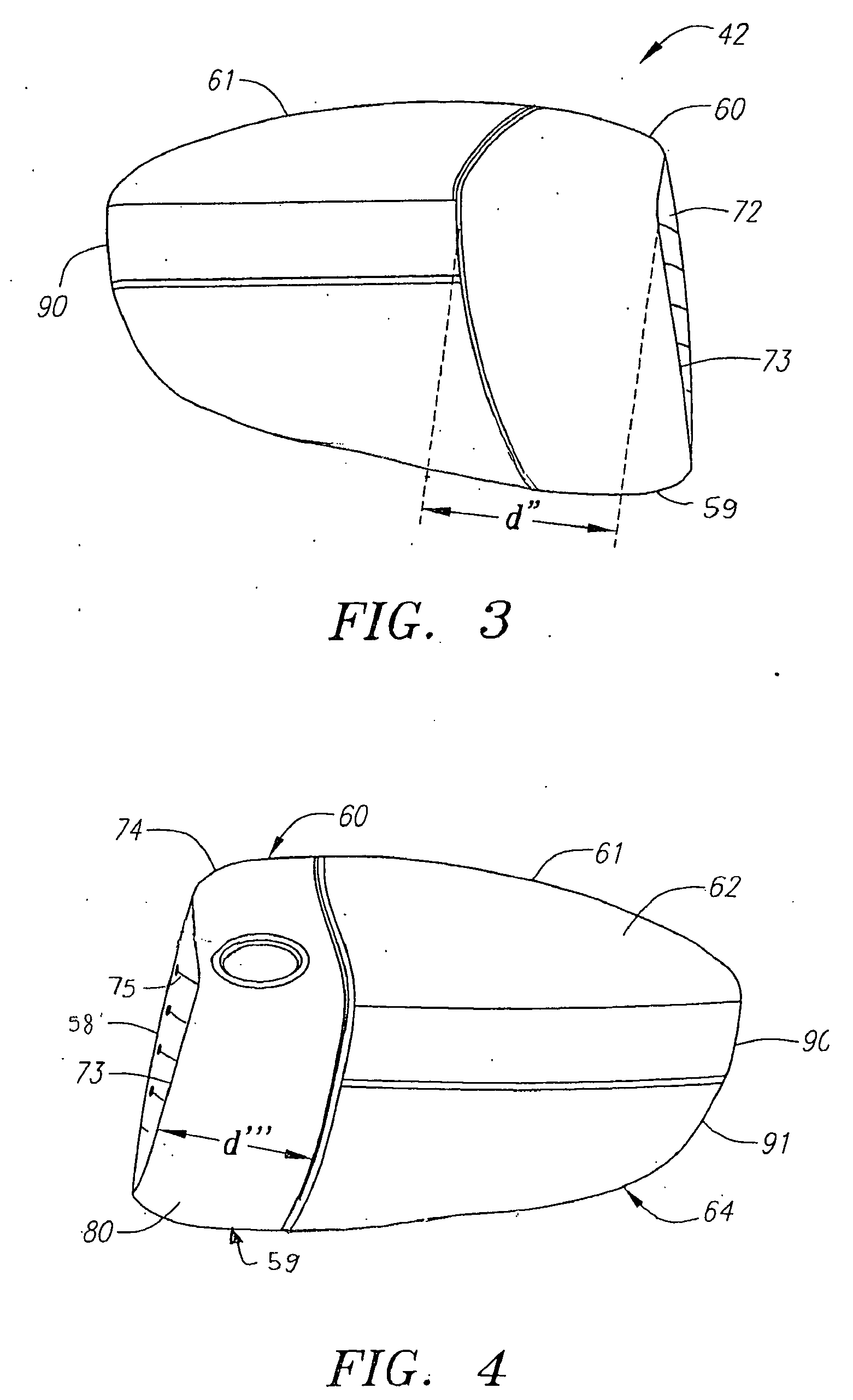

[0056] As shown in FIGS. 1-9, the club head 42 is generally composed of a face cup assembly 59 and an aft-body 61. The face cup assembly 59 is composed of a striking plate 58, a face component 60, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com