Uniform speed flow measuring device possessing speed raising function

A flow measurement device and functional technology, which is applied in the field of uniform velocity flow measurement devices, can solve the problems of no uniform velocity and narrow application range of pipe diameter, etc., and achieve the effects of good uniform velocity performance, increased signal boosting function, and low measurement lower limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

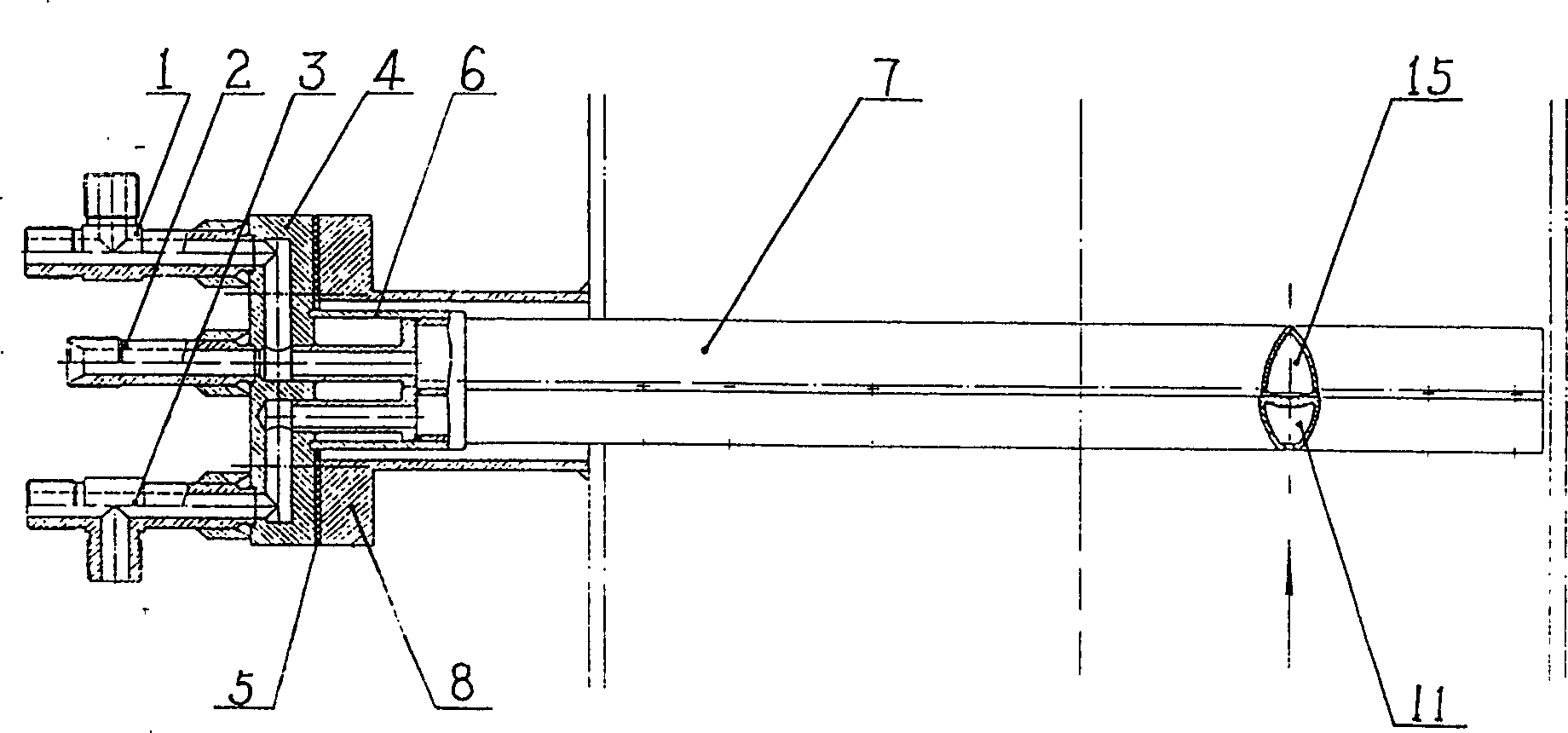

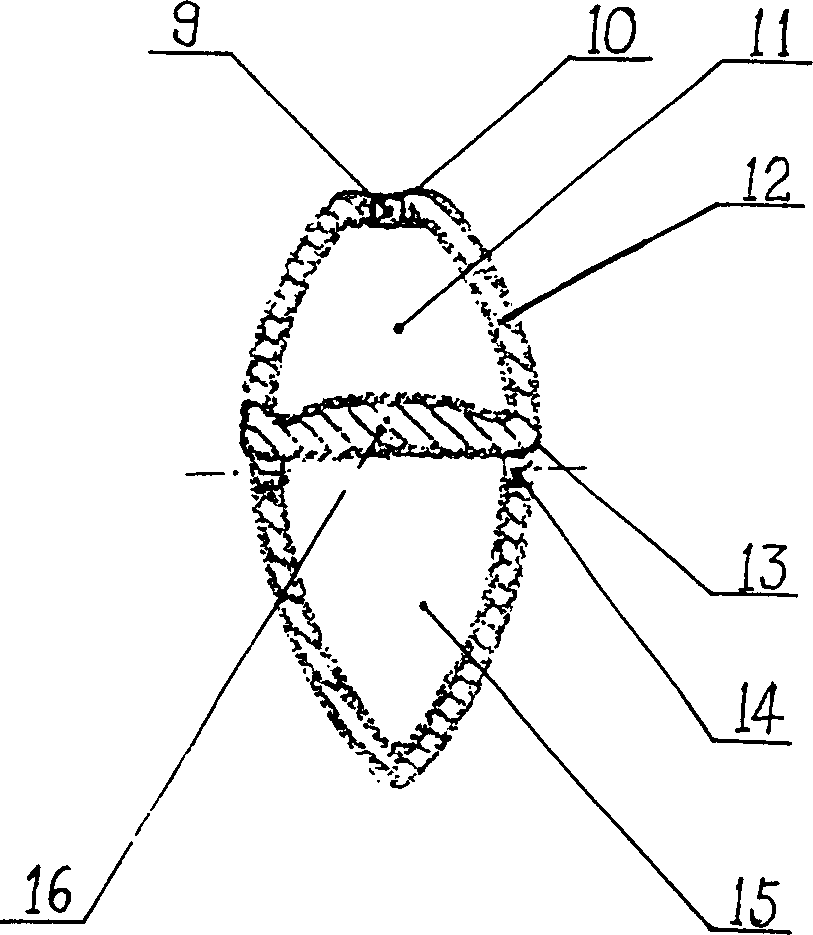

[0023] Example 1, see figure 1 , figure 2 . The product described in this embodiment 1 is composed of a measuring rod 7, a reinforcing sleeve 6, a mounting base 8, a sealing gasket 5 and a connecting head. Said measuring rod 7 is welded and installed on the lower side of the flanged connection plate 4 in the joint head. Three connection nozzles are installed on the upper surface of the flange connection plate 4: the total pressure connection nozzle 3, the temperature socket 2 and the static pressure connection nozzle 1, and there is also one on the total pressure connection nozzle 3 and the static pressure connection nozzle 1 Blow out the nozzle. Said measuring stick 7 cross section is " big head fish " shape, is made of total pressure pipe 11 and static pressure pipe 15 . The section of the tube wall 12 of said total pressure tube 11 and static pressure tube 15 is made of symmetrical arc and shared dividing plate 16 respectively, and the arc of total pressure tube 11 is ...

Embodiment 2

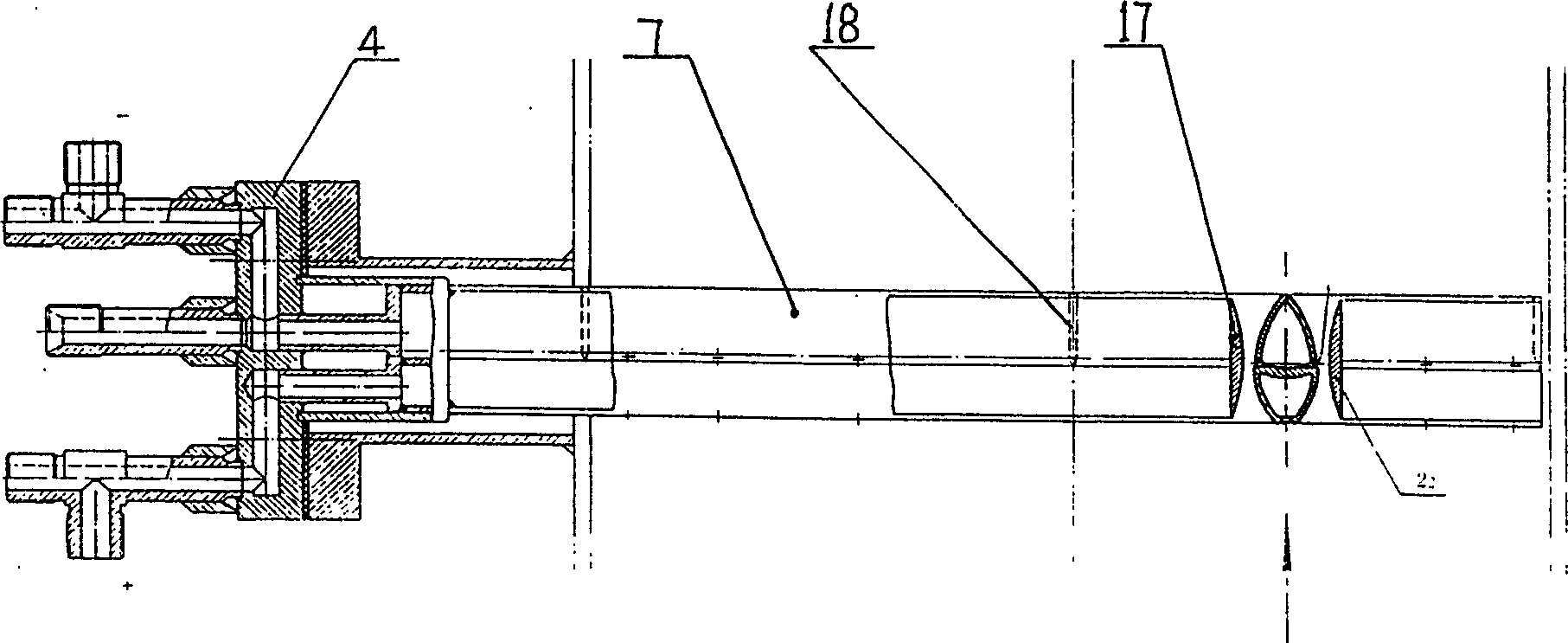

[0025] Example 2, see image 3 , Figure 4 . This program is improved on the basis of the measuring stick 7 described in Example 1, and its difference from Example 1 is that a speed-up plate 17 is added on both sides of the measuring stick 7, and the speed-up plate 17 is based on the measuring stick The axis of symmetry of the section is symmetrical and parallel to the measuring rod 7. The cross-section of the speed-raising plate 17 is equal in length to the cross-section of the measuring rod 7. The inner profile of the section is an arc line, and the outer profile is a straight line. A plurality of positioning partitions 18 are arranged along the length direction between the measuring rod 7 and the speed-increasing plate 17, and the measuring rod 7 is divided into two or more rectangular Venturi nozzles with precise dimensions. Taking pipe diameter D=400mm as an example, five positioning partitions 18 are set to divide the measuring rod 7 into four rectangular Venturi nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com