PTFE layers and methods of manufacturing

a technology applied in the field of ptfe layers and manufacturing methods, can solve the problems of largely unsatisfactory conventional ptfe layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

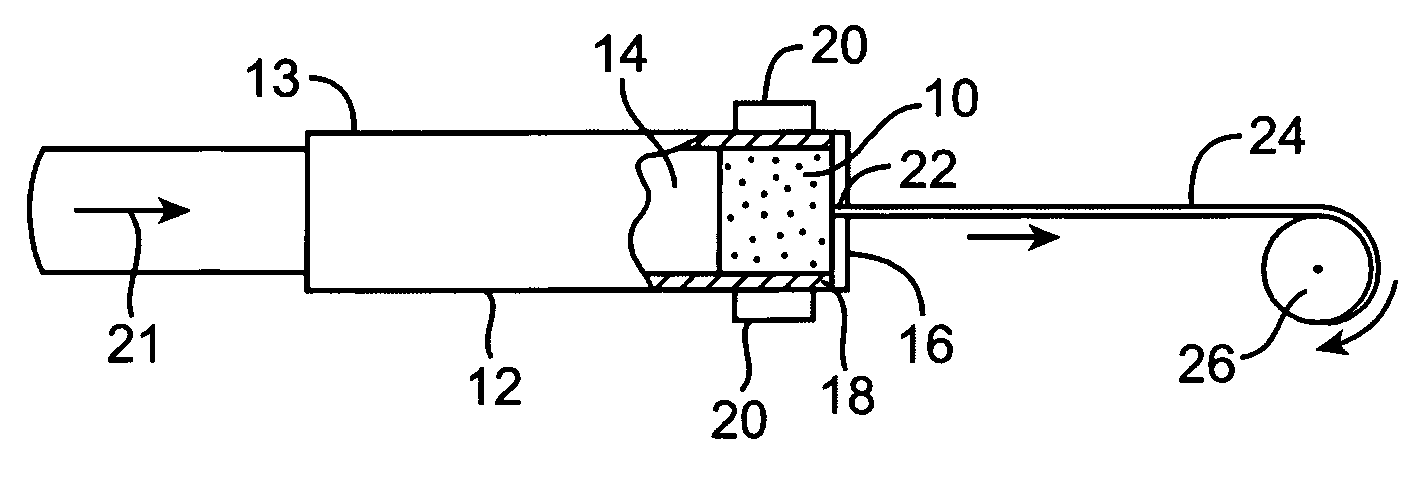

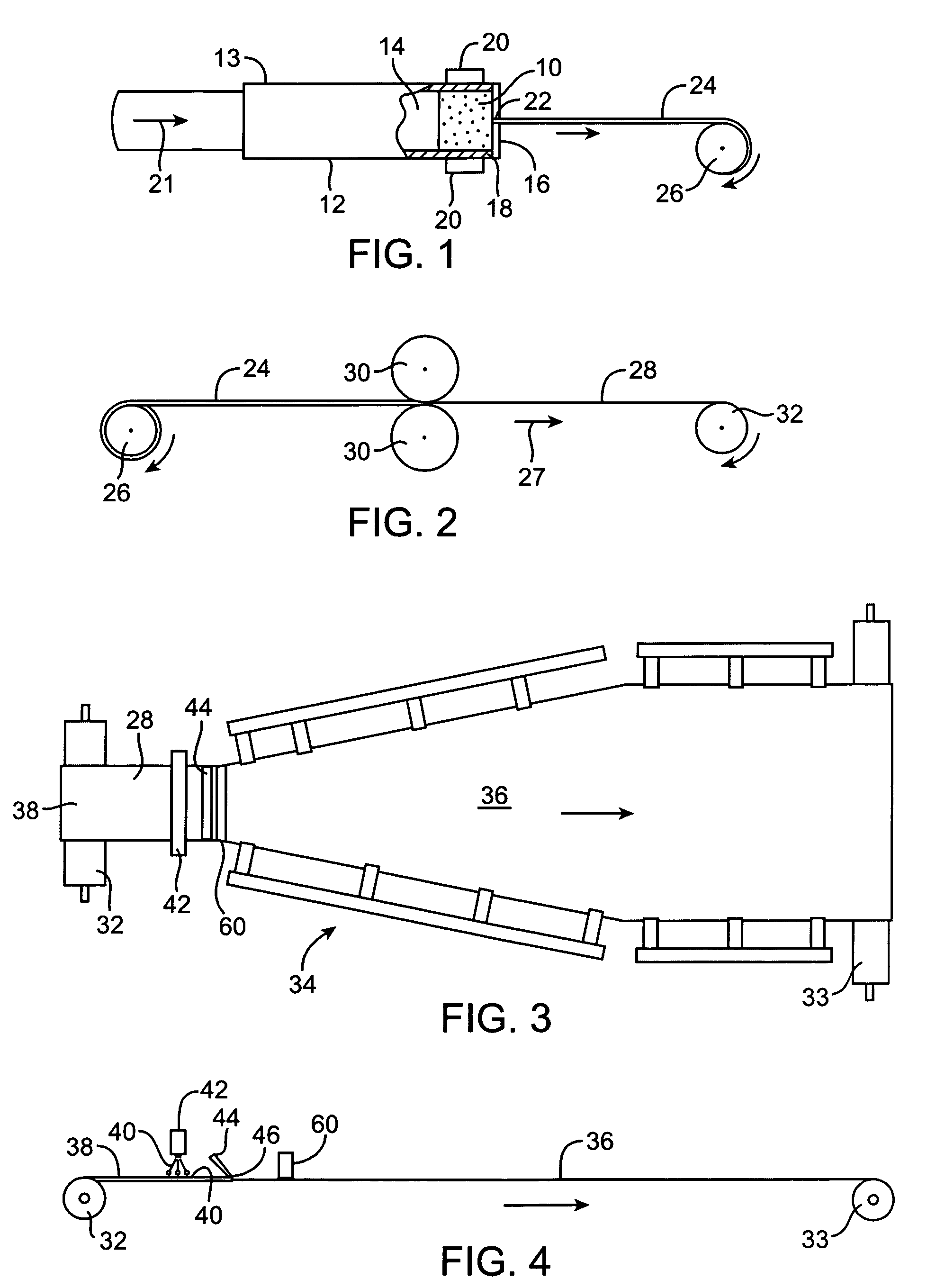

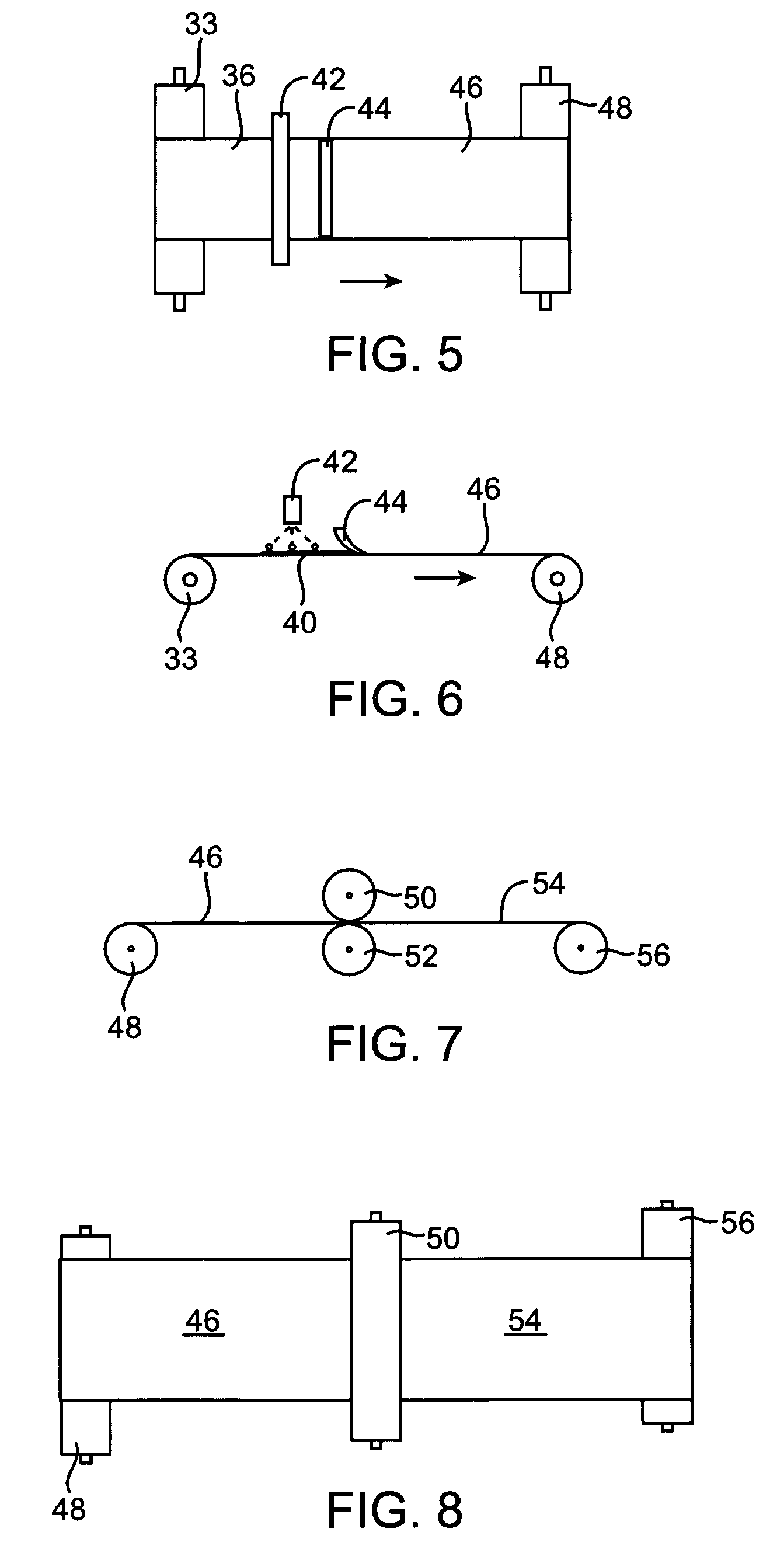

[0040] Embodiments of the present invention relate generally to thin PTFE layers, PTFE films, composite films having two or more PTFE layers and methods of manufacturing the PTFE layers, films and composite films. Some particular embodiments are directed to thin PTFE layers having low or substantially no fluid permeability with a microstructure that does not include significant fibril and nodal structure as is common with expanded PTFE layers. It may also be desirable for some embodiments of such thin PTFE layers that have a high degree of limpness and suppleness so to allow mechanical manipulation or strain of such a PTFE layer without significant recoil or spring back. Such PTFE layers may be manufactured and used for construction of endovascular grafts or other medical devices. For some applications, embodiments of PTFE films may include one or more discrete layers of PTFE that are secured together to form a composite film. As used herein, the term “composite film” generally refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com