Tubing connector

a technology of tubing connectors and connectors, which is applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of low cycle fatigue, failure of coiled tubing, and limit the length of coiled tubing allowed to be spooled thereon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

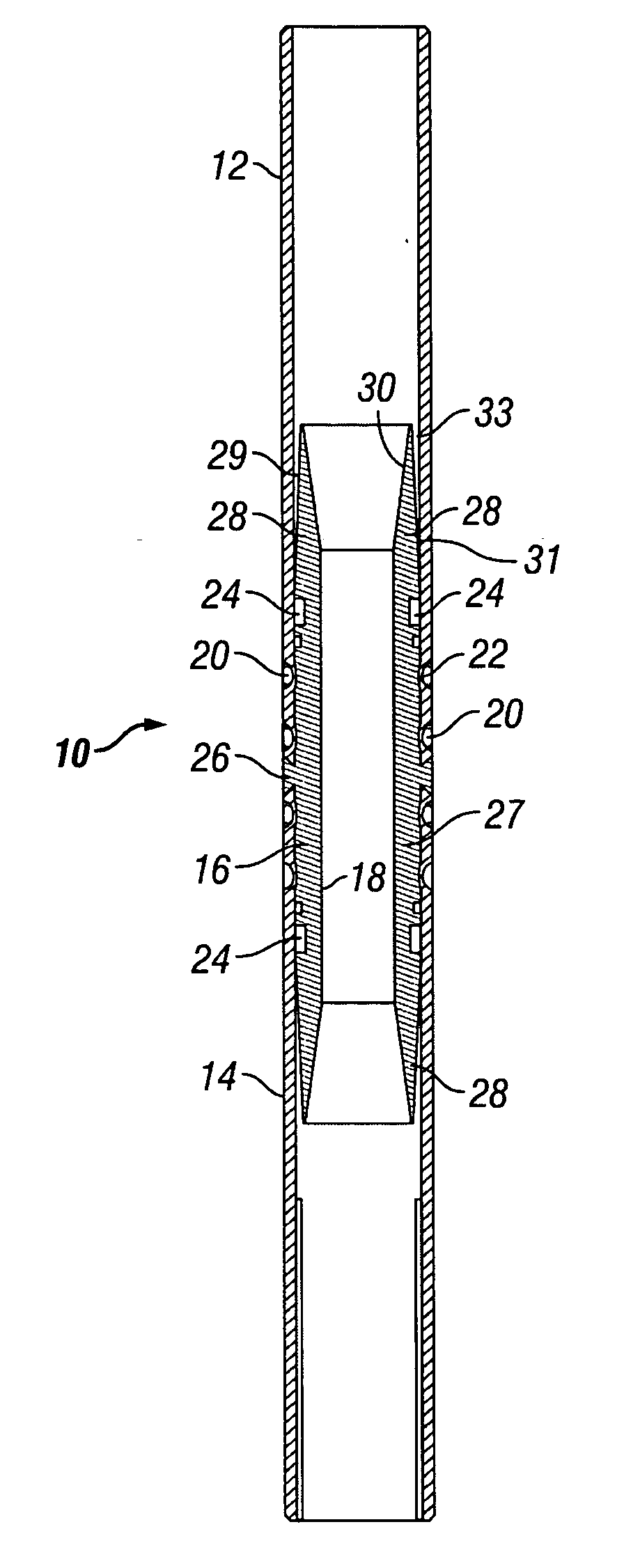

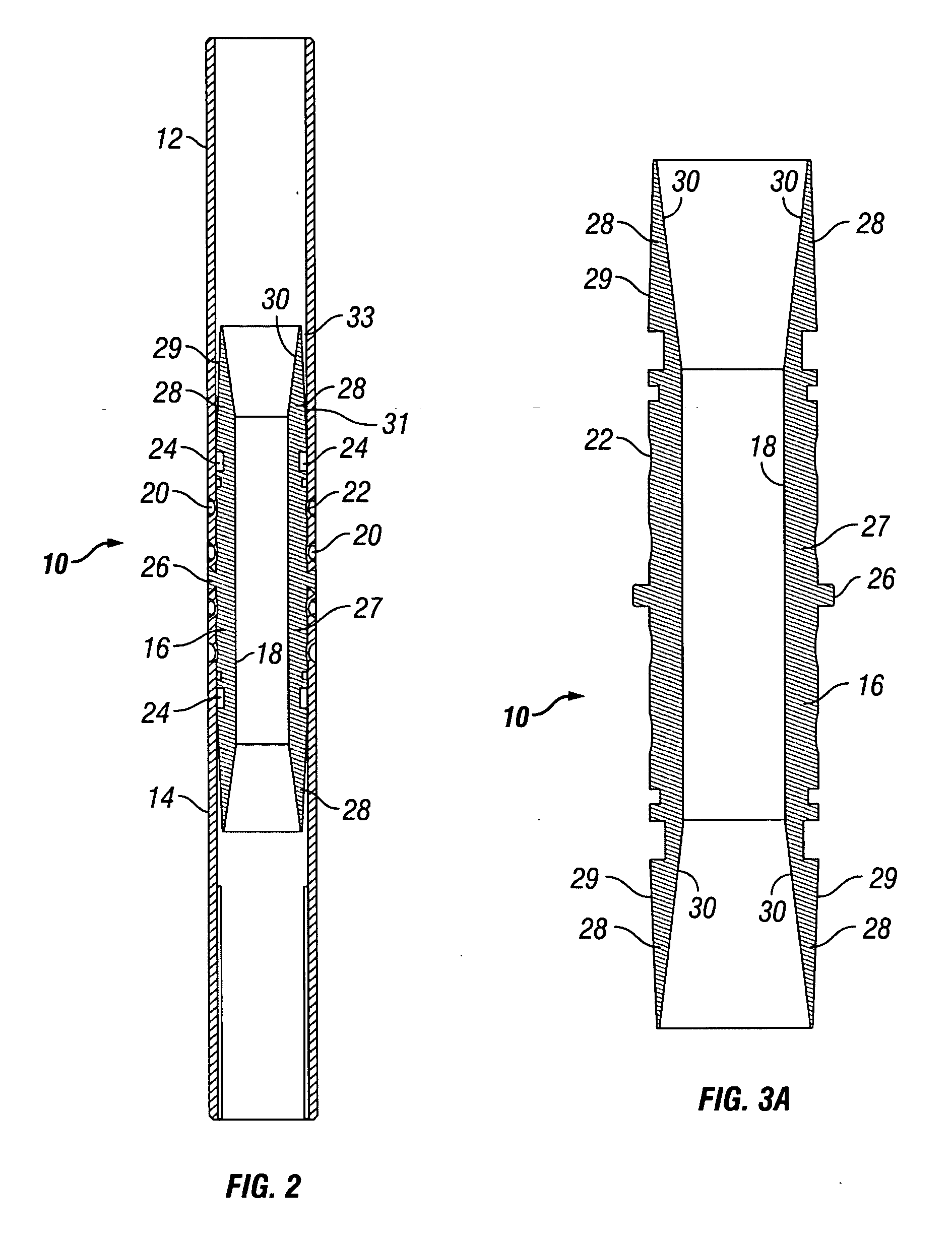

[0032] Referring to the drawings in detail, wherein like numerals denote identical elements throughout the several views, there is shown in FIG. 2 a coiled tubing connector 10 constructed in accordance with the present invention and in use to connect a first section of coiled tubing 12 and a second section of coiled tubing 14. The connector 10, having a body 16 having a longitudinal bore 18 therethrough, comprises a stiff section 27 and at least one end section 28. Often stiff section 27 is provided between two end sections 28, as is shown FIG. 2. In some embodiments, body 16 of connector 10 may be discontinuous, and in further embodiments, stiff section 27 is separable from one or more end sections 28. It is preferred for embodiments for connecting two sections of coiled tubing such as that shown in FIG. 2 that body 16 of connector 10 is a continuous body in which one region of connector body 16 is stiff section 27 and other region or regions of connector body 16 are end section or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com