Door operator assembly

a door operator and assembly technology, applied in the field of door operators, can solve the problems of failure of exterior application swing door operator, door to rapidly accelerate, and high installation cost of low-energy door operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is illustrated in further details by the following non-limiting examples.

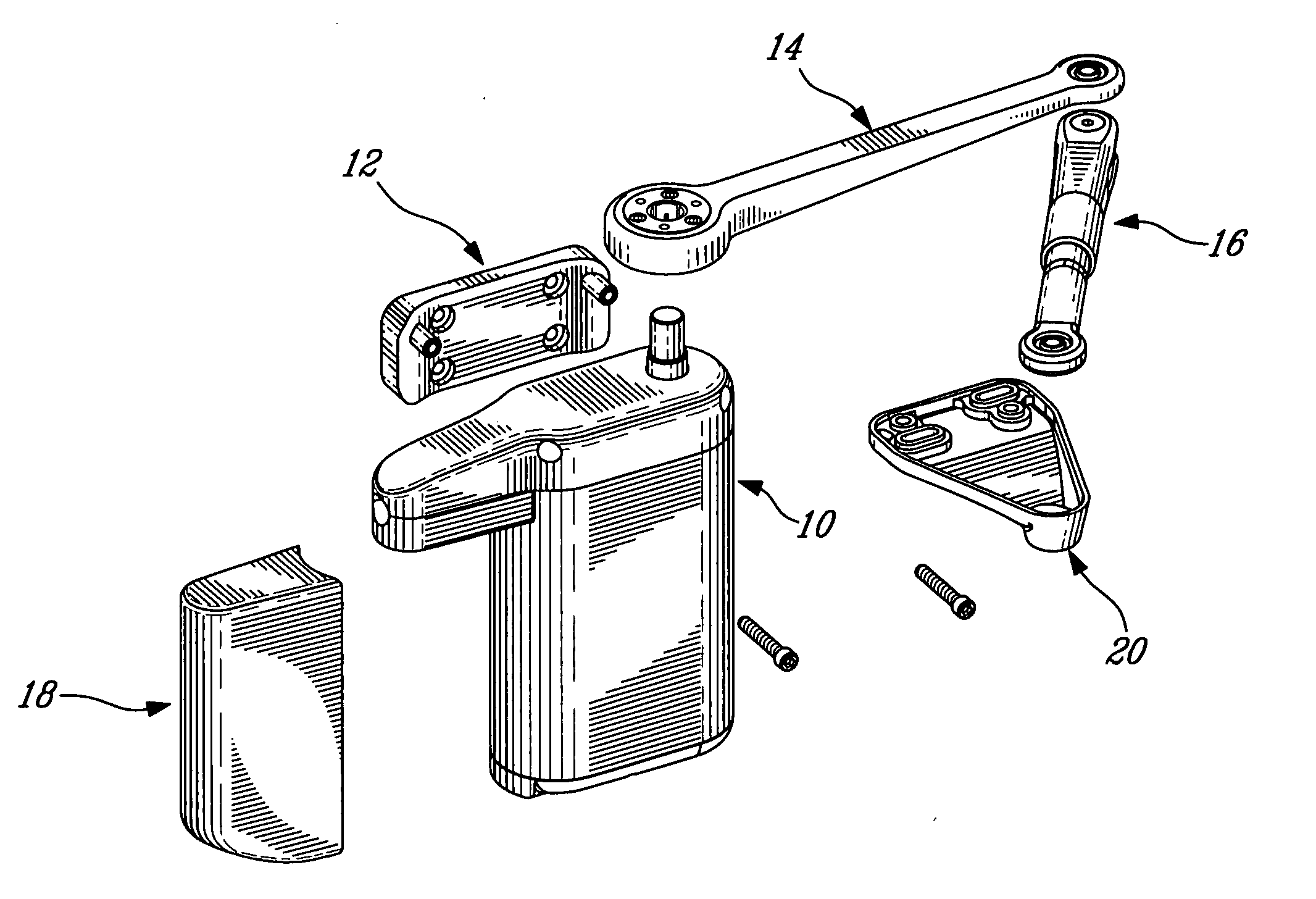

[0029] As illustrated in FIG. 3, a door operator assembly of the present invention comprises an operator unit 10 and a linkage.

[0030] The operator unity 10 is connected to a power storage pack 18 and mounted to a first position, relative to a door (not shown in FIG. 3), by a first mounting bracket 12. The linkage connects the operator unit 10 and a second position, relative to the door, the linkage being mounted at this second position by second mounting bracket 20.

[0031] The first mounting bracket 12 comprises two posts for example, and is of reduced dimensions, allowing an easy mounting.

[0032] As illustrated in FIG. 4, the operator unit 10 comprises an output drive unit 22, an input drive unit with controls 24, a cover 26 and a control cover 28.

[0033] The cover 26 may be used to provide a finished look to the door operator assembly. It is a non-structural member, and may be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com