Swivel connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

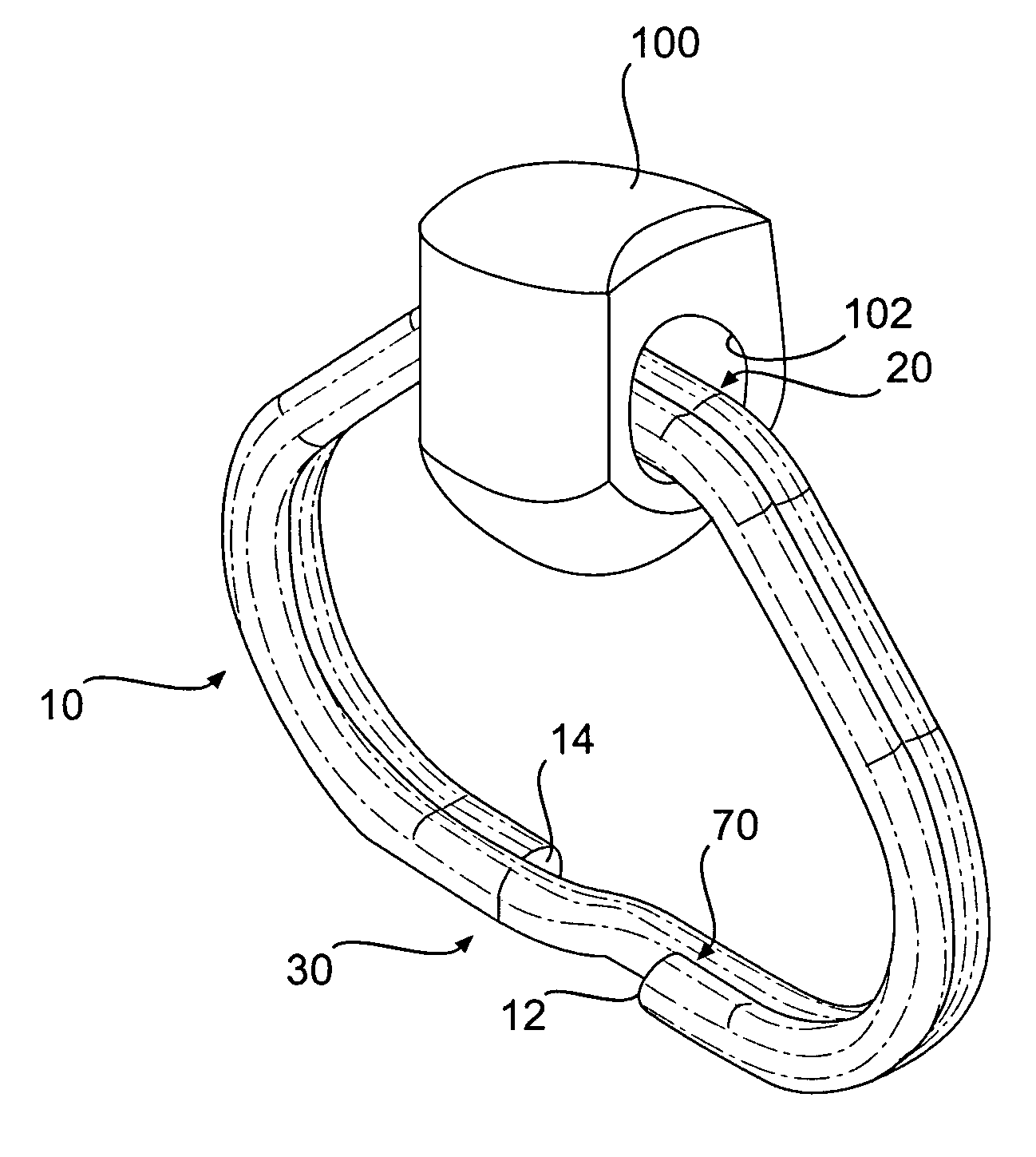

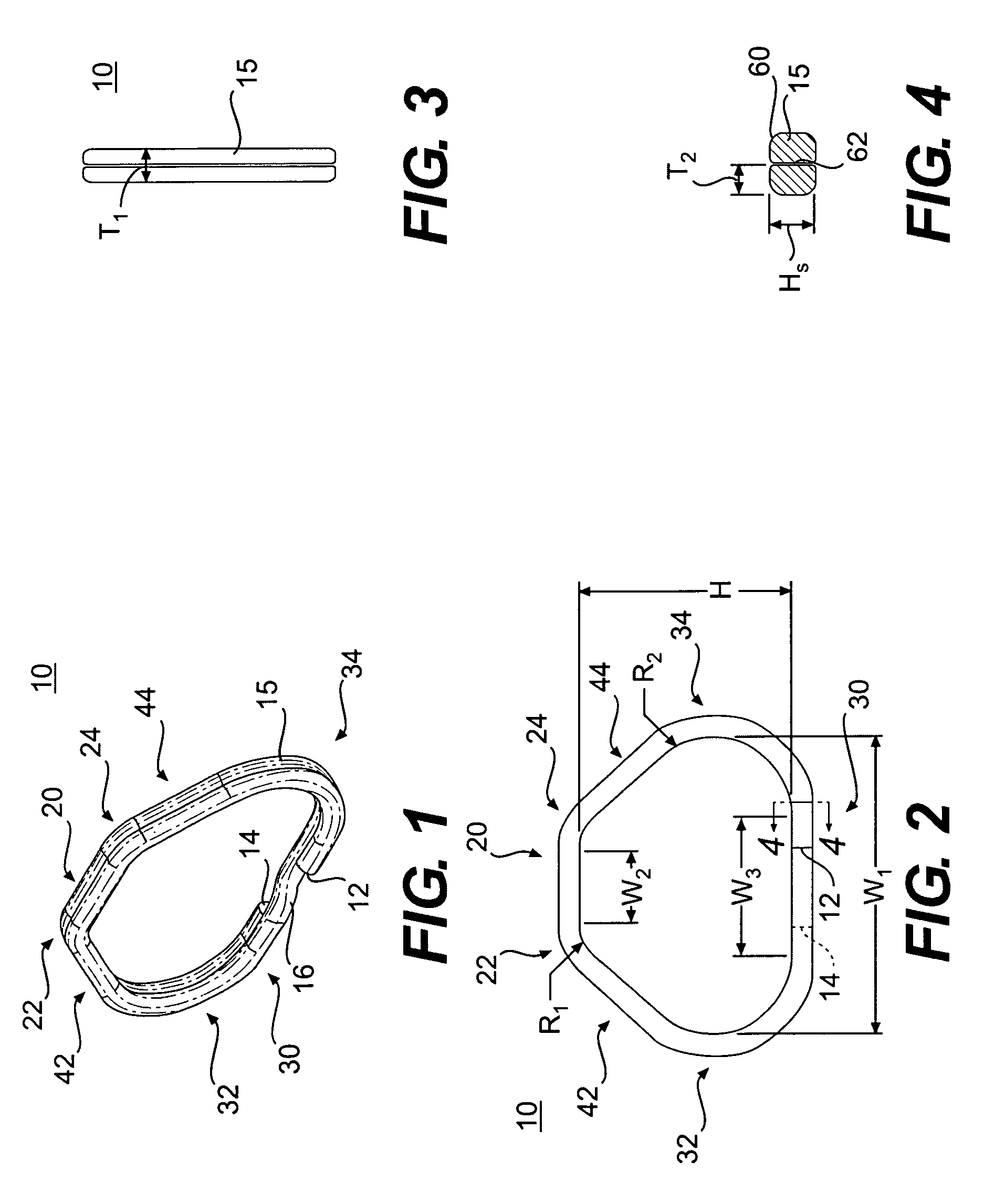

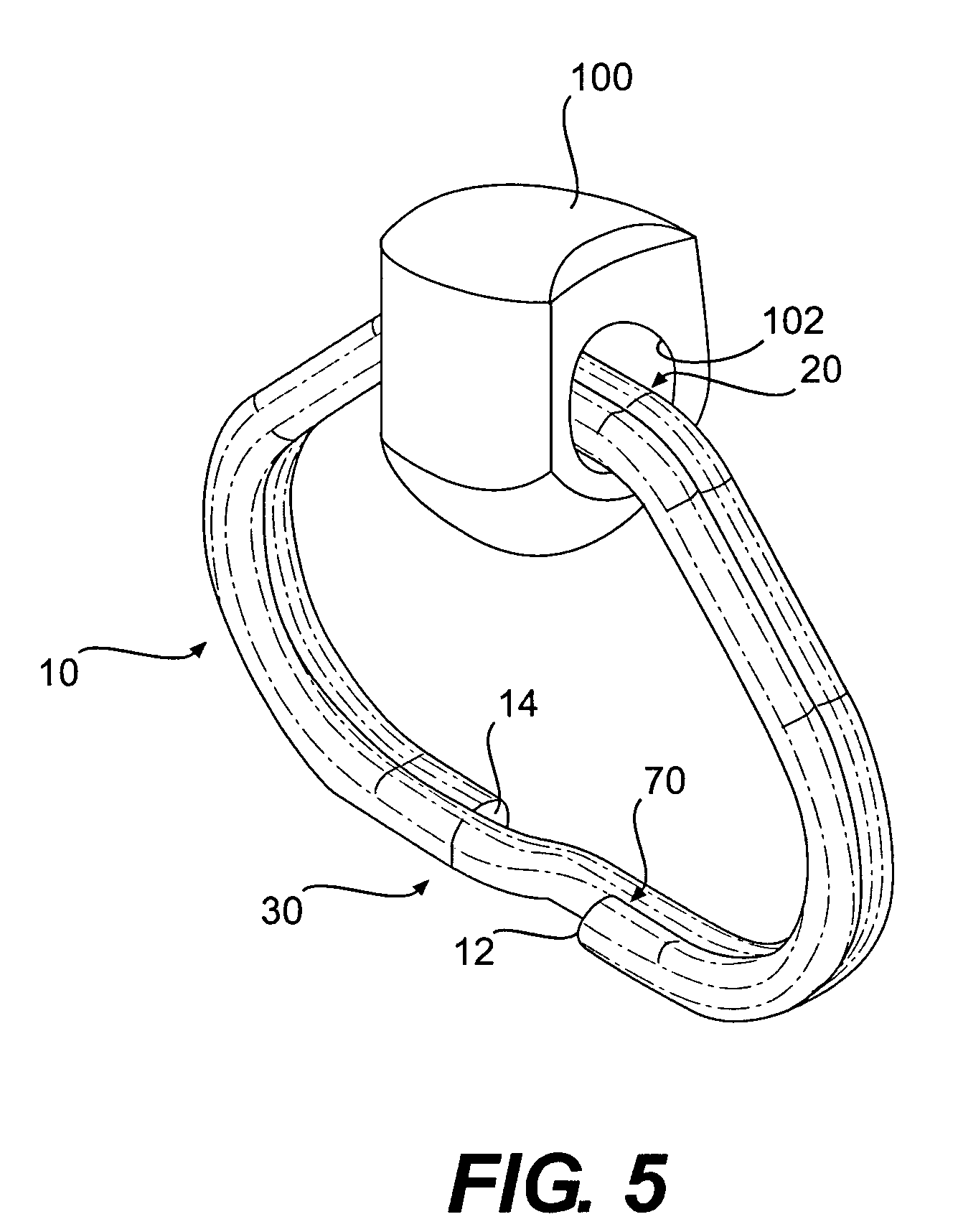

[0035] A swivel connector 10 as illustrated inFIGS. 1-5 is constructed from steel. The interior width W1 of the swivel connector 10 is 1.11 inches, the interior width W2 of the pivot section 20 is 5 / 16 inches, and the interior width W3 of the base 30 is 0.56 inches. The interior height H of the swivel connector 10 is ⅞ inches, the interior radii R1 of the upper corners 22, 24 are both ⅛ inches, and the interior radii R2 of the lower corners 32, 34 are both 0.275 inches. The thickness T1 of the double wound strip 15 is 0.12 inches, the thickness T2 of a single winding of the material strip 15 is 0.06 inches, and its height HS is 0.08 inches. The swivel connector 10 is formed by mandrel winding followed by coining in a die to create outside radii on the steel wire. The swivel connector 10 is coated with a corrosion resistant black zinc finish.

[0036] In this specification, the term “wound” does not necessarily indicate a structure formed by a winding process involving an actual windin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap