Washing machine

a washing machine and drum technology, applied in the field of washing machines, can solve the problems of reducing the capacity of the washing machine, increasing the vibration of the drum, and adding the additional balance weight, so as to reduce the wash capacity, reduce the effect of drum imbalance, and reduce the size of the washing machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Reference will now be made in detail to the preferred embodiment of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

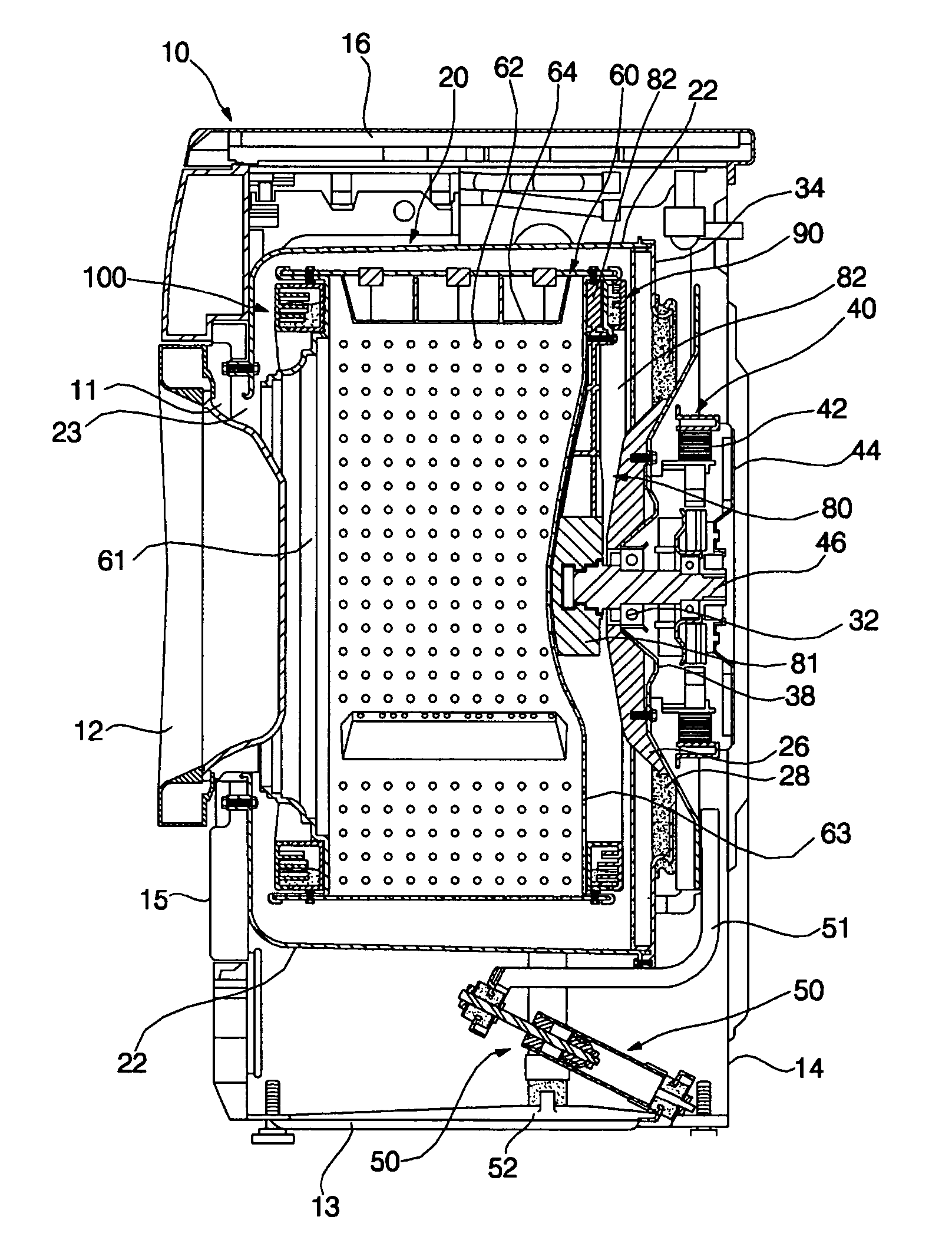

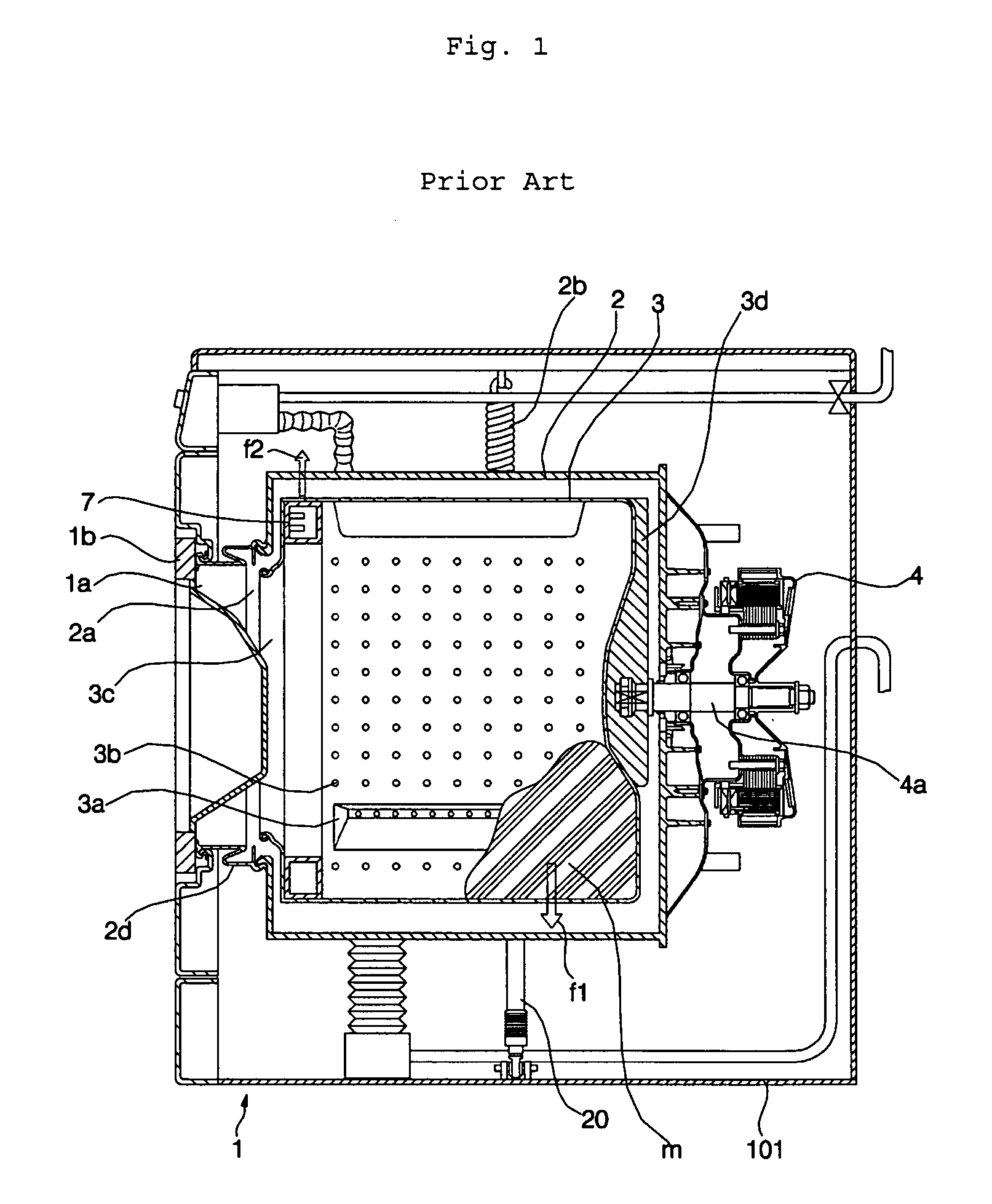

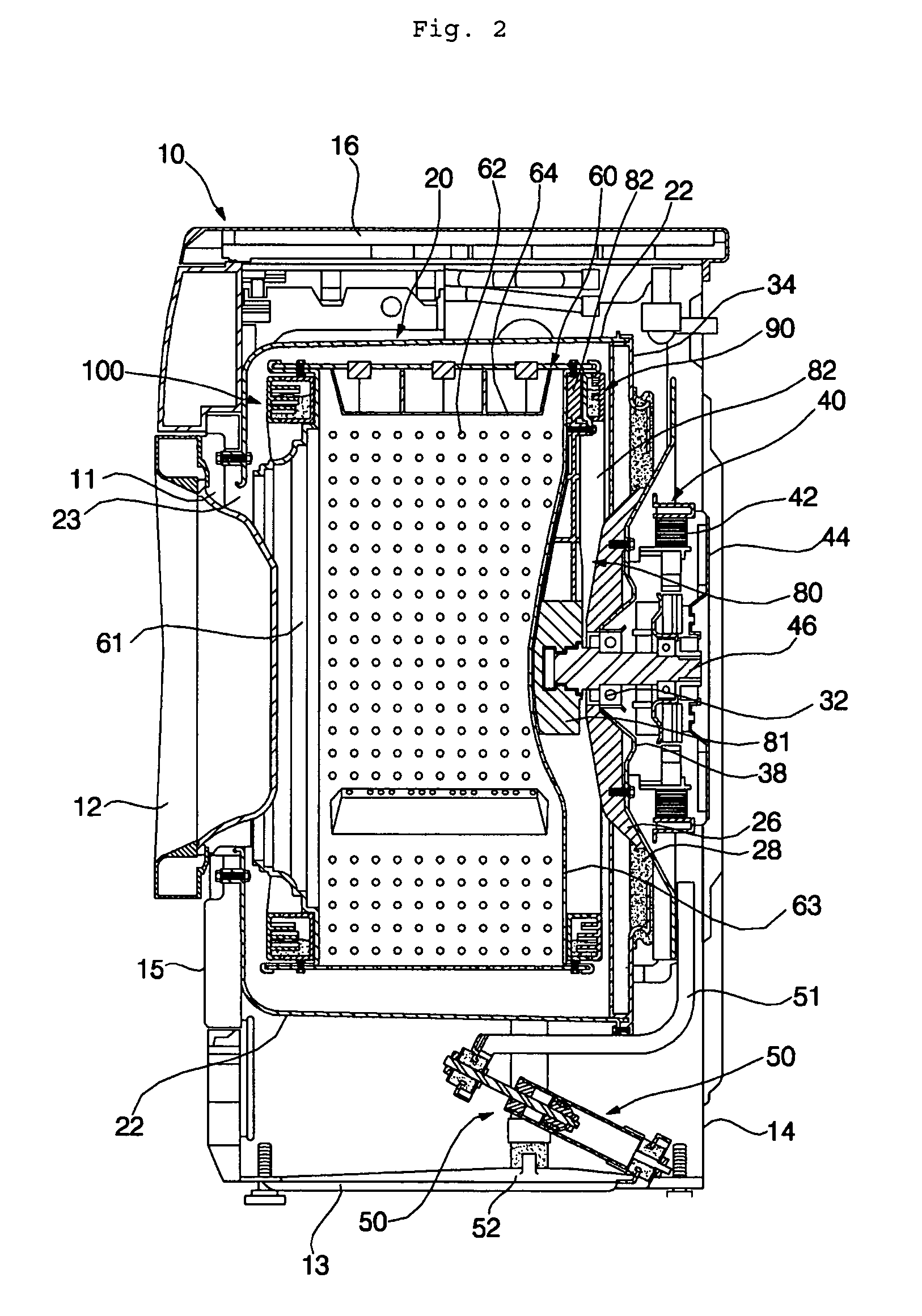

[0048]FIG. 2 is a partially cut-away sectional view of a washing machine in accordance with an embodiment of the present invention.

[0049] As shown in FIG. 2, the washing machine according to the present embodiment comprises a cabinet 10 forming an outer appearance of the washing machine. The cabinet 10 is formed at a front surface portion thereof with a laundry entrance / exit opening 11. A door 12 is pivotally connected by use of a hinge to open and close the laundry entrance / exit opening 11.

[0050] Specifically, the cabinet 10 includes a base 13, a cabinet body 14 disposed on the base 13 for forming opposite lateral surface portions and rear surface portion of the washing machine, a cabinet cover 15 dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com