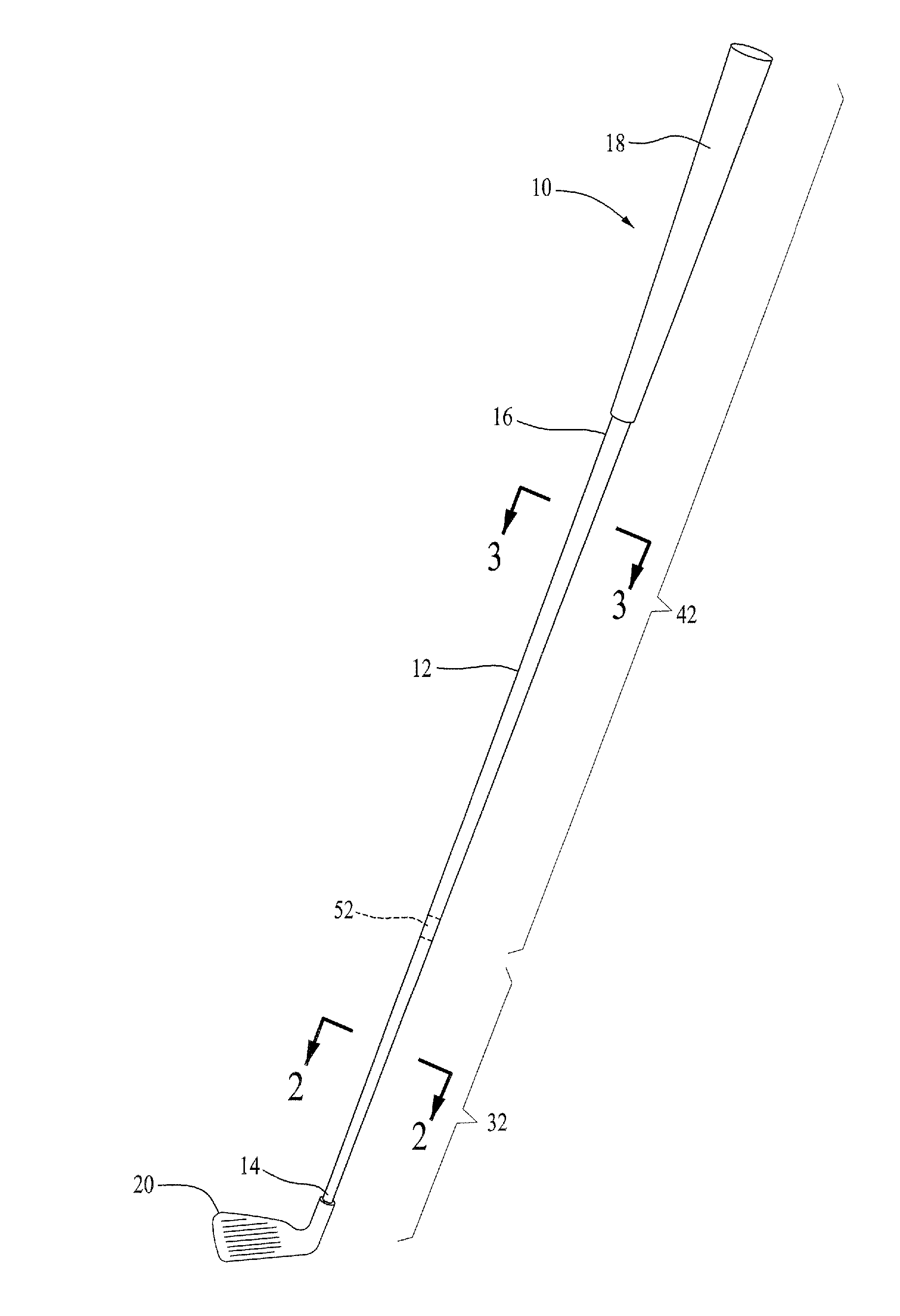

Method of making a weighted golf swing trainer

a swing trainer and weight technology, applied in the field of golf swing practice equipment, can solve the problems of inability to actually hit a golf ball with the trainer to provide, inability to use flowable materials, and inability to achieve the effect of delivering a golf ball, so as to achieve the effect of increasing swing speed, significant muscle-building benefits, and building “fast-twitch” muscles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

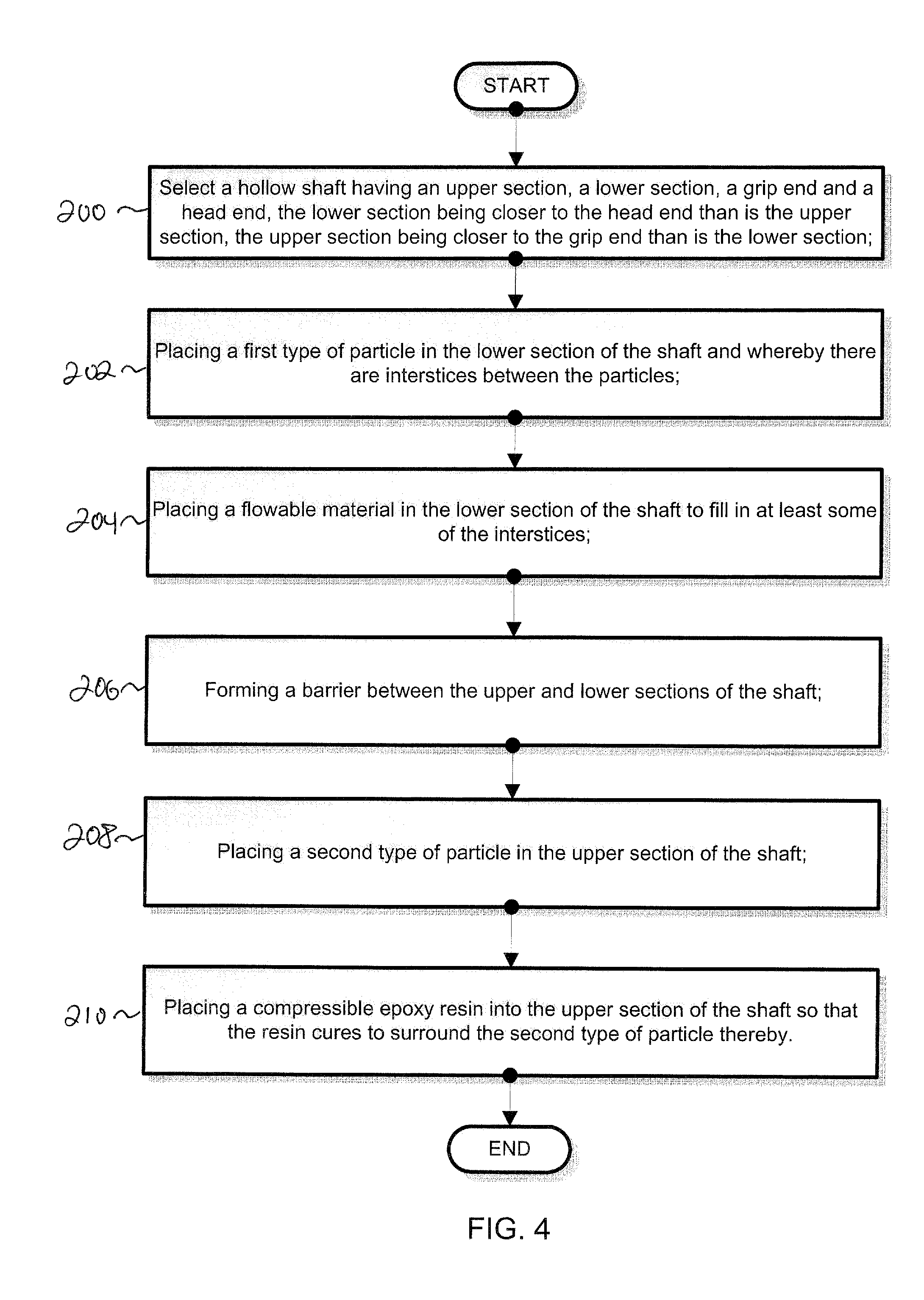

Method used

Image

Examples

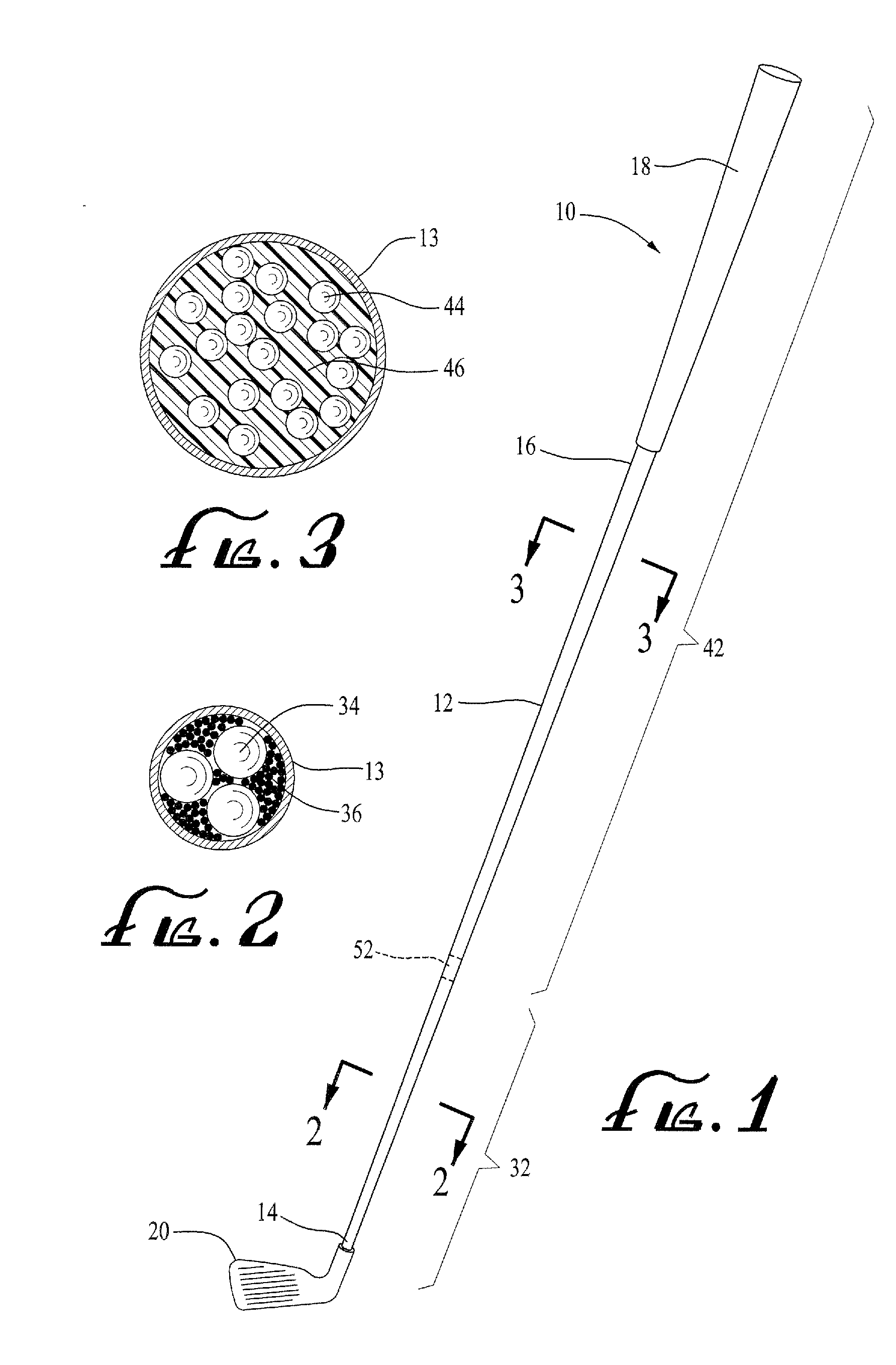

example 1

Preparing Seven Iron

[0060] A. Men's Seven Iron—A men's seven iron was prepared by placing the following materials into a shaft in this order: [0061] Lead shot, #5—4.5 ounces [0062] Tungsten powder—2.8 ounces [0063] Barrier [0064] Lead shot, #8—14.1 ounces and polyurethane resin, two components mixed, to fill the remaining shaft.

[0065] Preferably, a finished men's seven iron should measure approximately 36.5 inches in length and have a finished weight of approximately 2 pounds and 8 ounces. A properly manufactured club should have an exact center point of about 18.25 inches and a balance point of approximately 2.25 inches measured from the exact center toward the head end (plus or minus 0.5 inches). [0066] B. Ladies Seven Iron—A ladies seven iron was prepared by placing the following materials into a shaft in this order: [0067] Lead shot, #5—2.8 ounces [0068] Tungsten powder—1.4 ounces [0069] Barrier [0070] Lead shot, #8—9.7 ounces and polyurethane resin, two components mixed, to f...

example 2

Preparing Driver

[0072] A. Men's Driver—A men's driver was prepared by placing the following materials into a shaft in this order: [0073] Lead shot, #5—4 ounces [0074] Tungsten powder—2.8 ounces [0075] Barrier [0076] Lead shot, #10—3.0 ounces [0077] Lead shot, #5—10 ounces [0078] Polyurethane resin, two components mixed, to fill the remaining shaft while placing the lead shot above the barrier.

[0079] Preferably, a finished men's driver should measure approximately 44 inches in length and have a finished weight of approximately 2 pounds and 4 ounces. A properly manufactured club should have an exact center point of about 22 inches and a balance point of approximately 2.5 inches measured from the exact center toward the head end (plus or minus 0.5 inches). Such measurements assume that the club is being made with a training grip (ergonomic). Standard grips will result in clubs that are approximately 2 ounces lighter.

[0080] B. Ladies Driver—A ladies driver was prepared by placing the...

example 3

Wedge Legal for Use on a Golf Course

[0088] A. Men's Legal Wedge—A wedge legal for use on a golf course was prepared by placing the following materials into a shaft, in this order. [0089] Lead shot, #10—5.5 ounces [0090] Tungsten powder—3.5 ounces [0091] Lead shot, #5—5.5 ounces

[0092] Preferably, a finished men's legal wedge should measure approximately 35 inches in length and have a finished weight of approximately 2.0 pounds. A properly manufactured club should have an exact center point of about 17.5 inches and a balance point of approximately 5.5 inches measured from the exact center toward the head end (plus or minus 0.5 inches). Such measurements assume that the club is being made with a training grip (ergonomic). Standard grips will result in clubs that are approximately 2 ounces lighter.

[0093] B. Ladies Legal Wedge—A wedge legal for use on a golf course was prepared by placing the following materials into a shaft, in this order. [0094] Lead shot, #10—4.5 ounces [0095] Tung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com