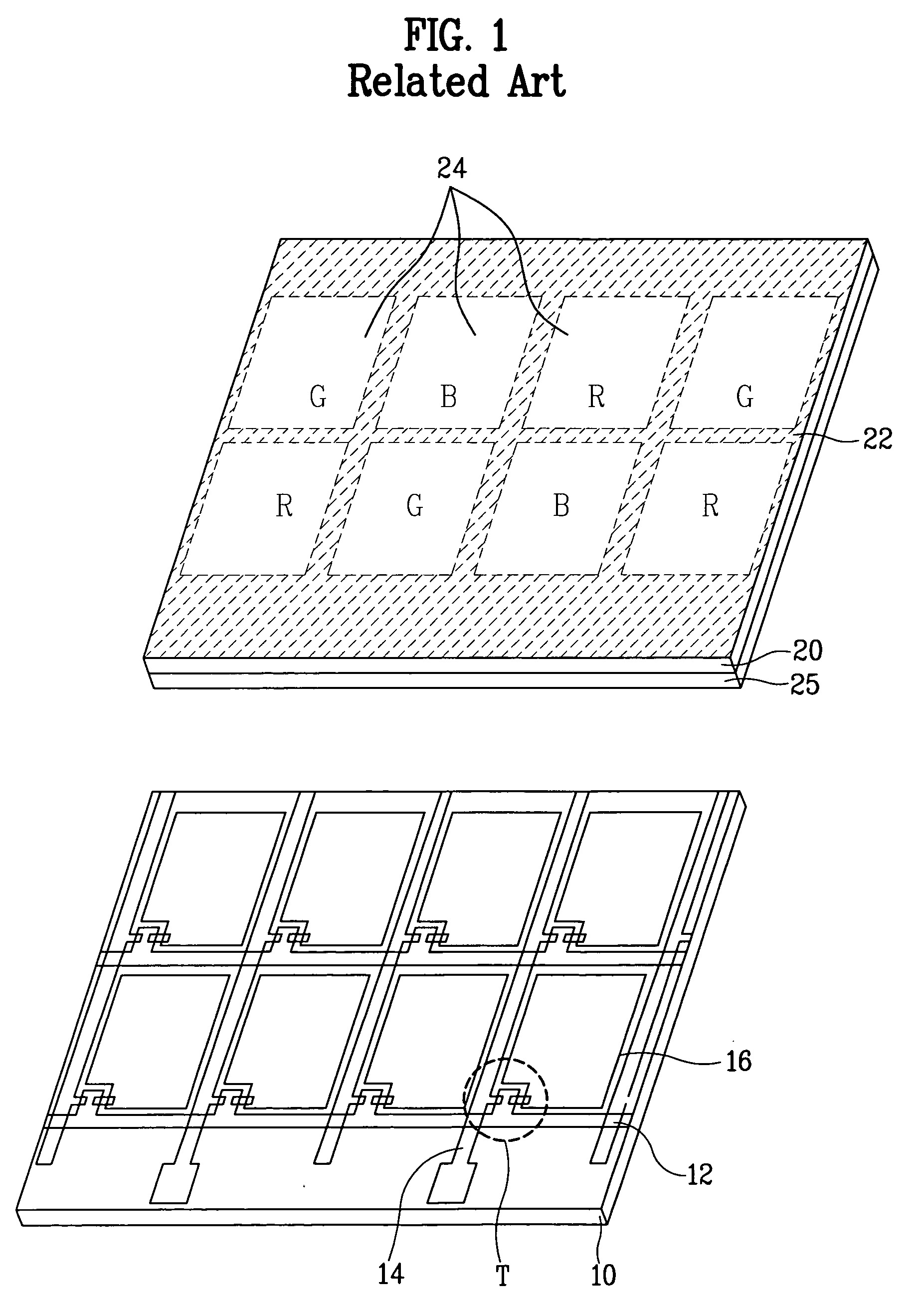

Liquid crystal display device and method of fabricating the same

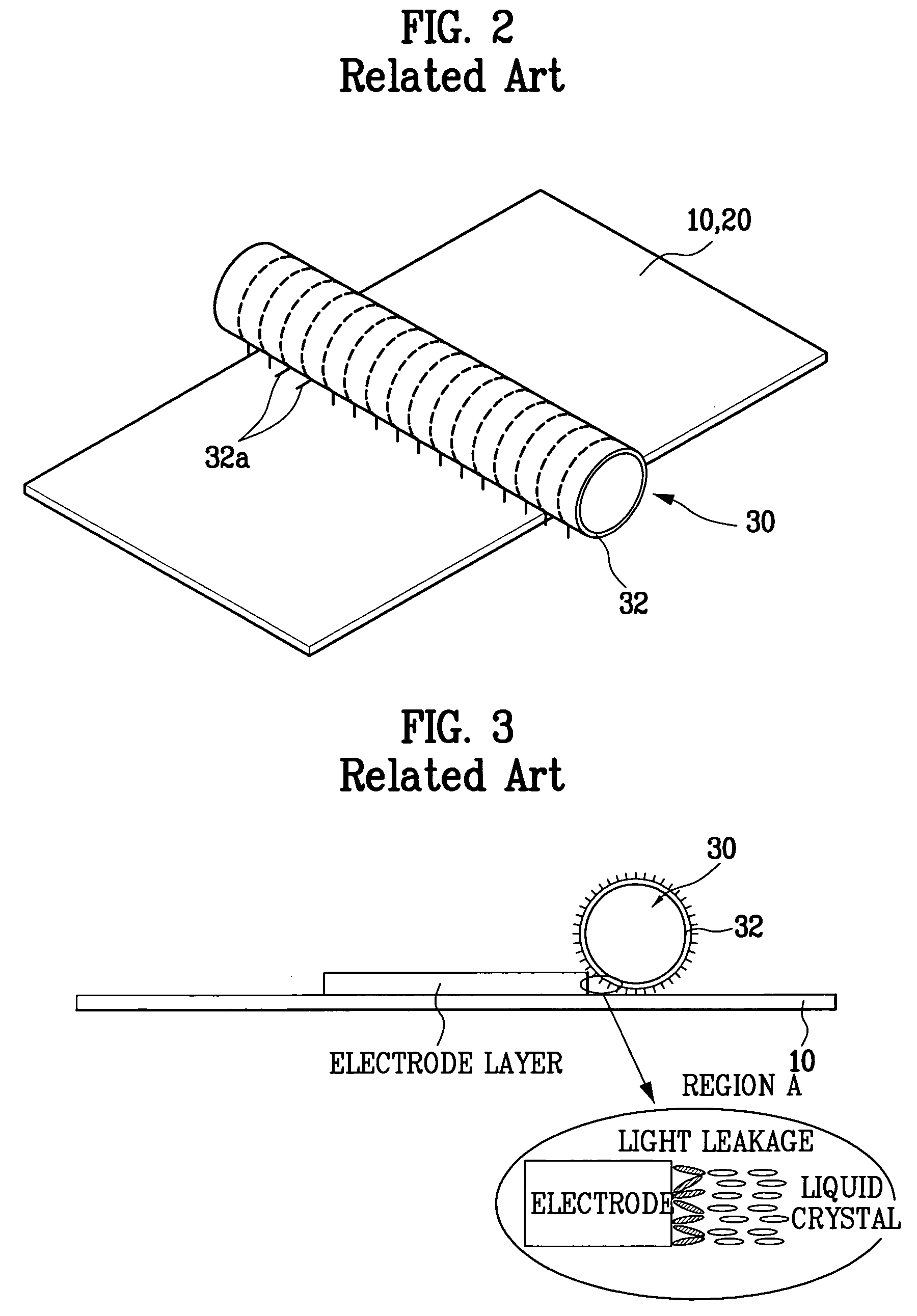

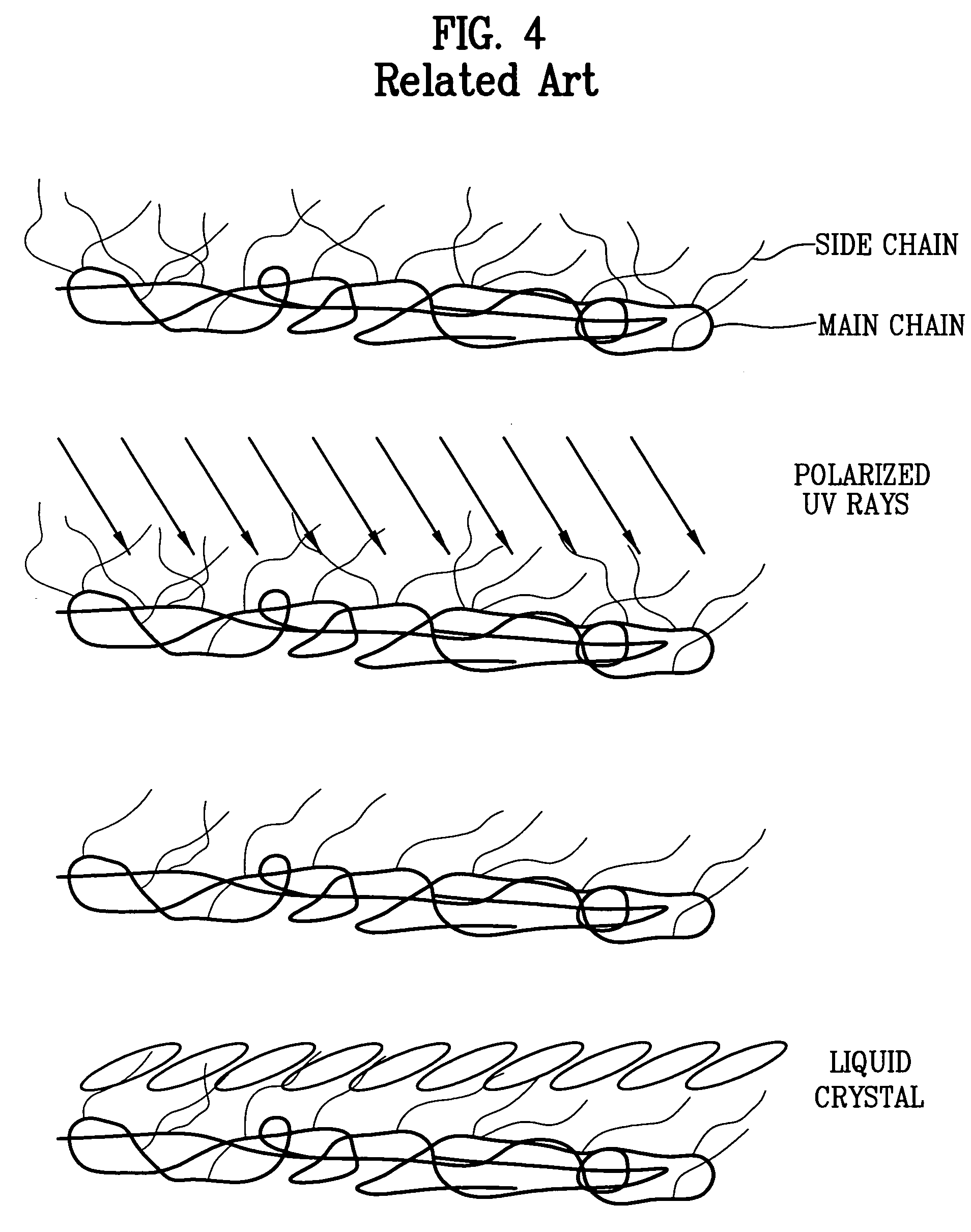

a technology of liquid crystal display and liquid crystal layer, which is applied in the direction of thin material processing, instruments, chemistry apparatus and processes, etc., can solve the problems of problematic light leakage, difficult to achieve a consistent arrangement of molecules in the liquid crystal layer, and difficulty in achieving light leakage in the region of the liquid crystal layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0040] The invention addresses the problems of the conventional methods by combining a rubbing alignment method and a photo-alignment method. In other words, with the rubbing alignment method, when arrangement of a rubbing cloth becomes disordered or the rubbing cloth fails to contact the substrate, the alignment material coated on a region does not align with a constant alignment direction. Thus, the inventors of the present application recognized this problem and conceived a method for causing the portion(s) of the alignment material not aligned by the rubbing alignment method of the related art to be aligned by a photo-alignment method configured to address this need. Also, using the rubbing alignment method so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com