Striking plate for golf club head

a golf club head and strike plate technology, applied in the field of strike plates, can solve the problems of shortening the life of the golf club head, and achieve the effect of improving the vibration resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

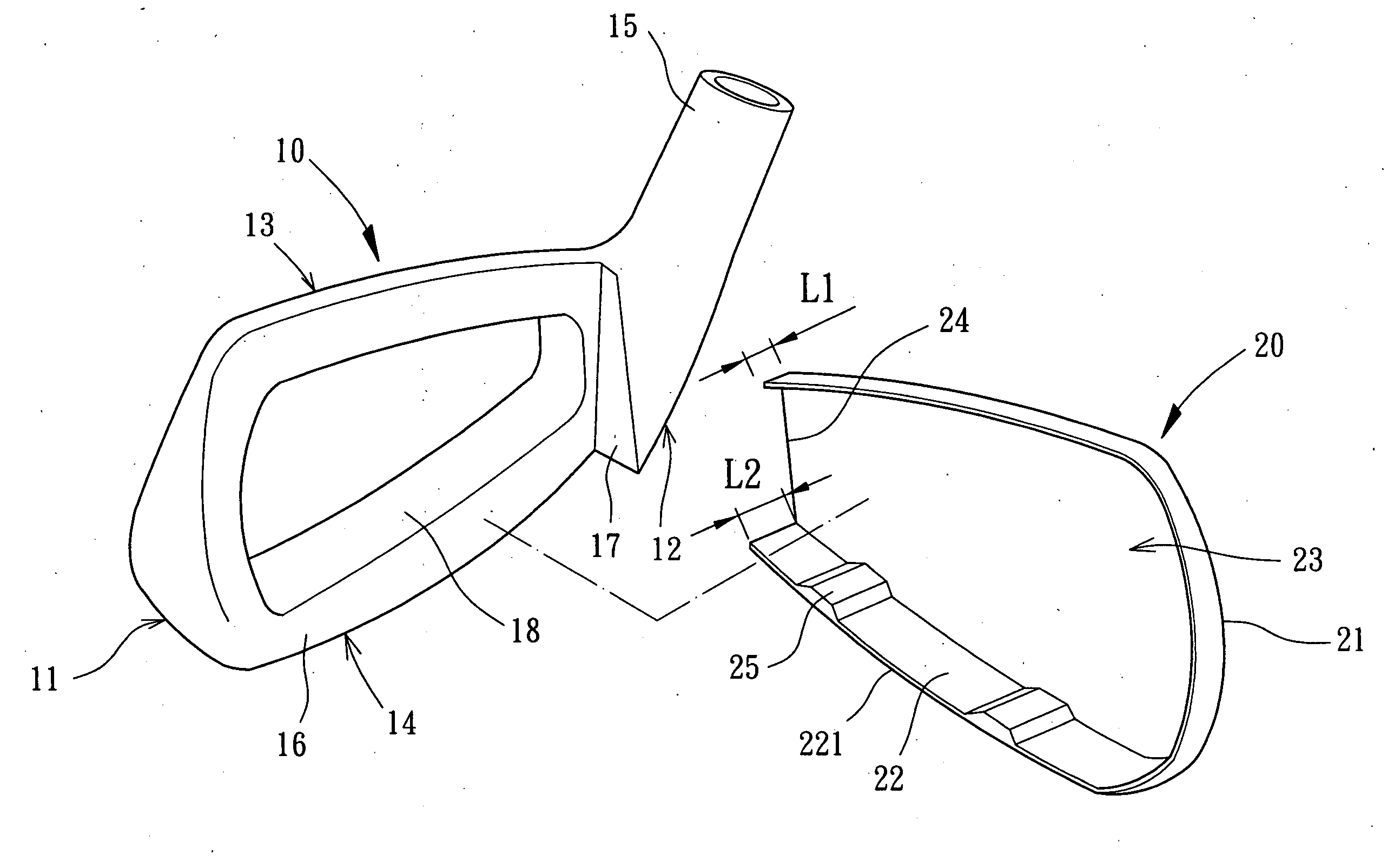

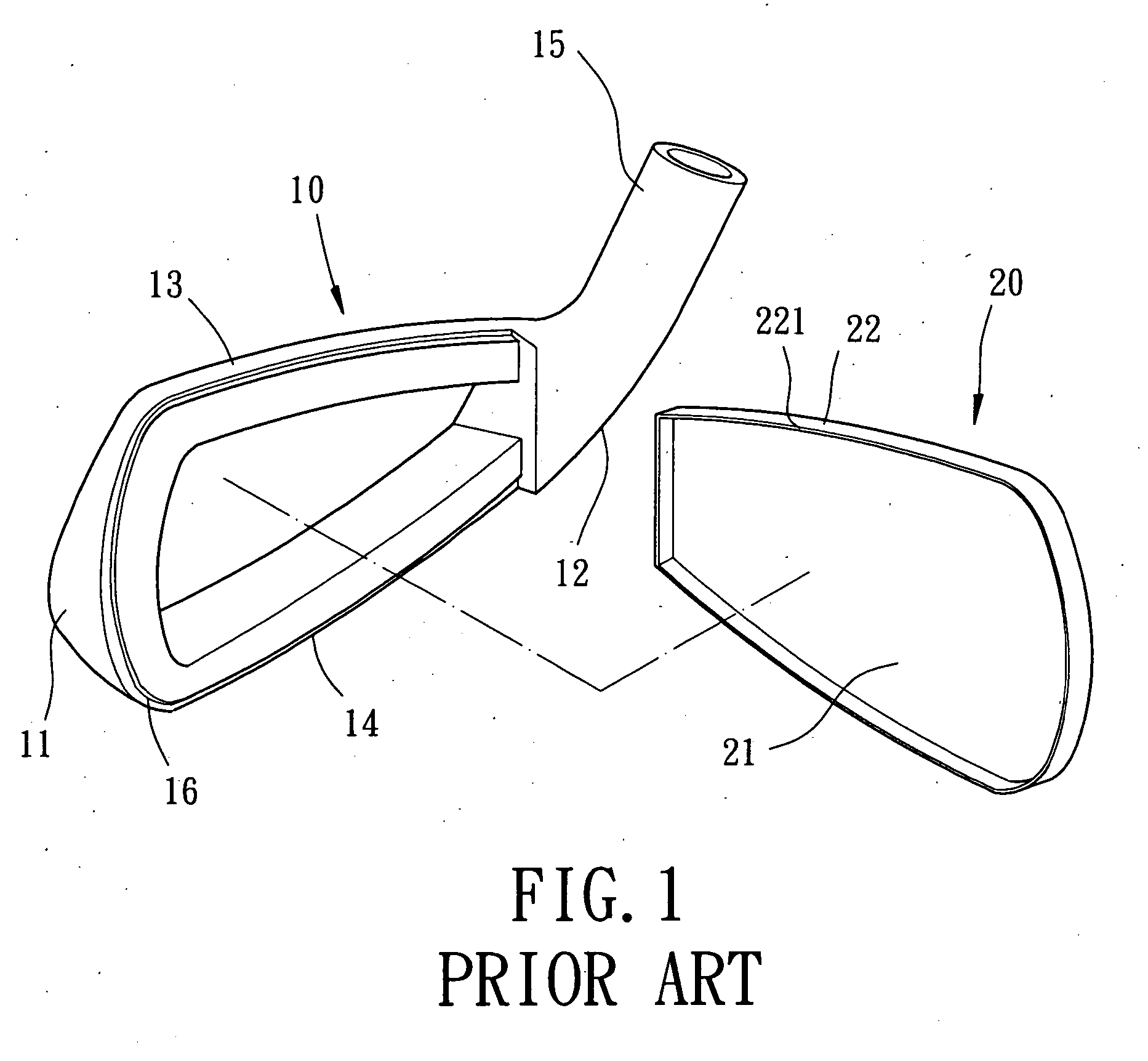

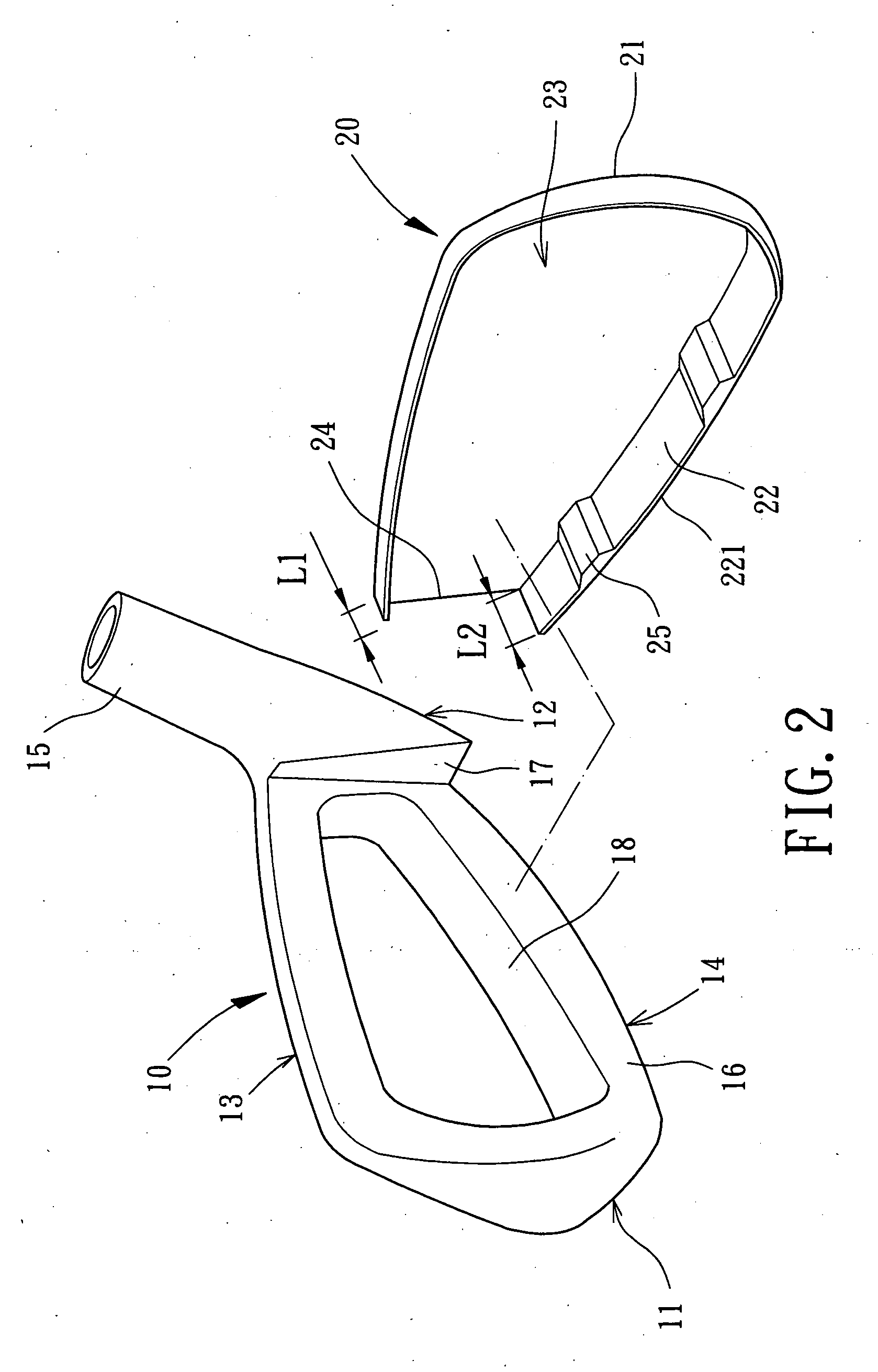

[0025]FIG. 2 shows a golf club head with a striking plate in accordance with the present invention. The golf club head comprises a body 10 and a striking plate 20. In the illustrated embodiment, the golf club head is of iron type. Nevertheless, the striking plate 20 in accordance with the present invention can be used with golf club heads of other types, such as wood type, utility type, putter type, etc.

[0026] Still referring to FIG. 2, the body 10 is preferably made of metal, alloy, or non-metal material and formed by casting, forging, or mechanic processing. The body 10 comprises a toe 11, a heel 12, a crown (or blade) 13, and a sole 14. A hosel 15 is formed on a side of the body 10 for coupling with a shaft (not shown). The body 10 further comprises a coupling section 16 and a sidewall portion 17. Preferably, the body 10 further comprises a cavity 18 having an open or closed end. The coupling section 16 is substantially a front perimeter face on a front side of the body 10. The s...

second embodiment

[0034]FIG. 4 illustrates the striking plate 20 in accordance with the present invention, wherein the striking plate 20 is used with a wood type golf club head. Similarly, the perimeter wall 22 with varied width provides the sweet spot of the striking portion 22 with improved elastic deformability, whereas the reinforcing protrusions 25 effectively avoid cracking of the sidewall 22 or the welding bead, thereby preventing the striking plate 20 from being disengaged or damaged. The vibration resistance of the golf club head is improved and the life of the golf club head is prolonged.

[0035]FIG. 5 illustrates a third embodiment modified from the first embodiment. In this embodiment, two reinforcing protrusions 25 are formed on the inner face of the top portion of the perimeter wall 22 and located adjacent to the toe 11 or the heel 12. The reinforcing protrusions 25 effectively avoid cracking of the sidewall 22 or the welding bead, thereby preventing the striking plate 20 from being disen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com