Fast set screw device for non-metallic boxes

a non-metallic box, fast technology, applied in the direction of coupling device connection, machine support, mechanical apparatus, etc., can solve the problems of disadvantage of both types of retaining device, and achieve the effect of enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

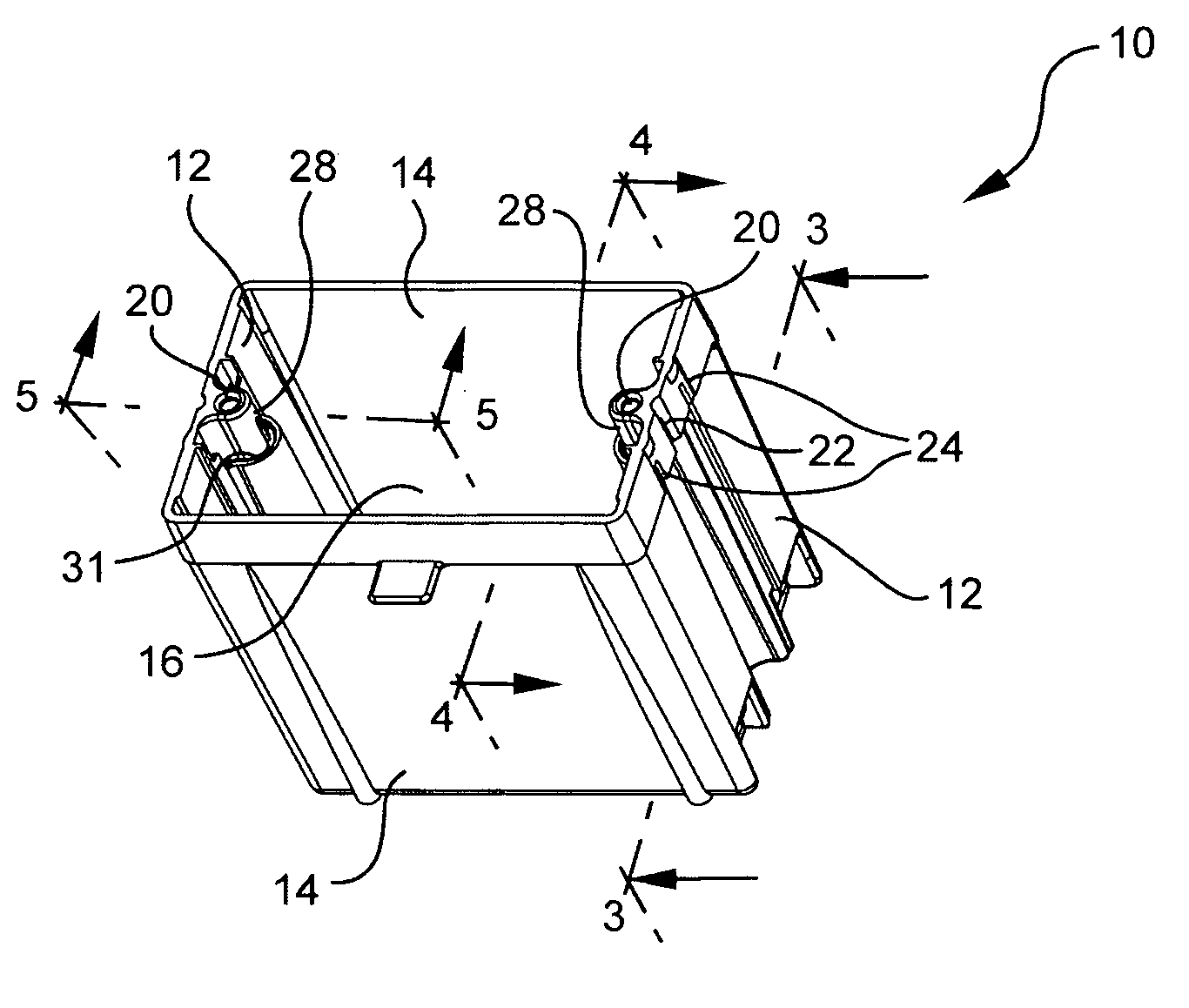

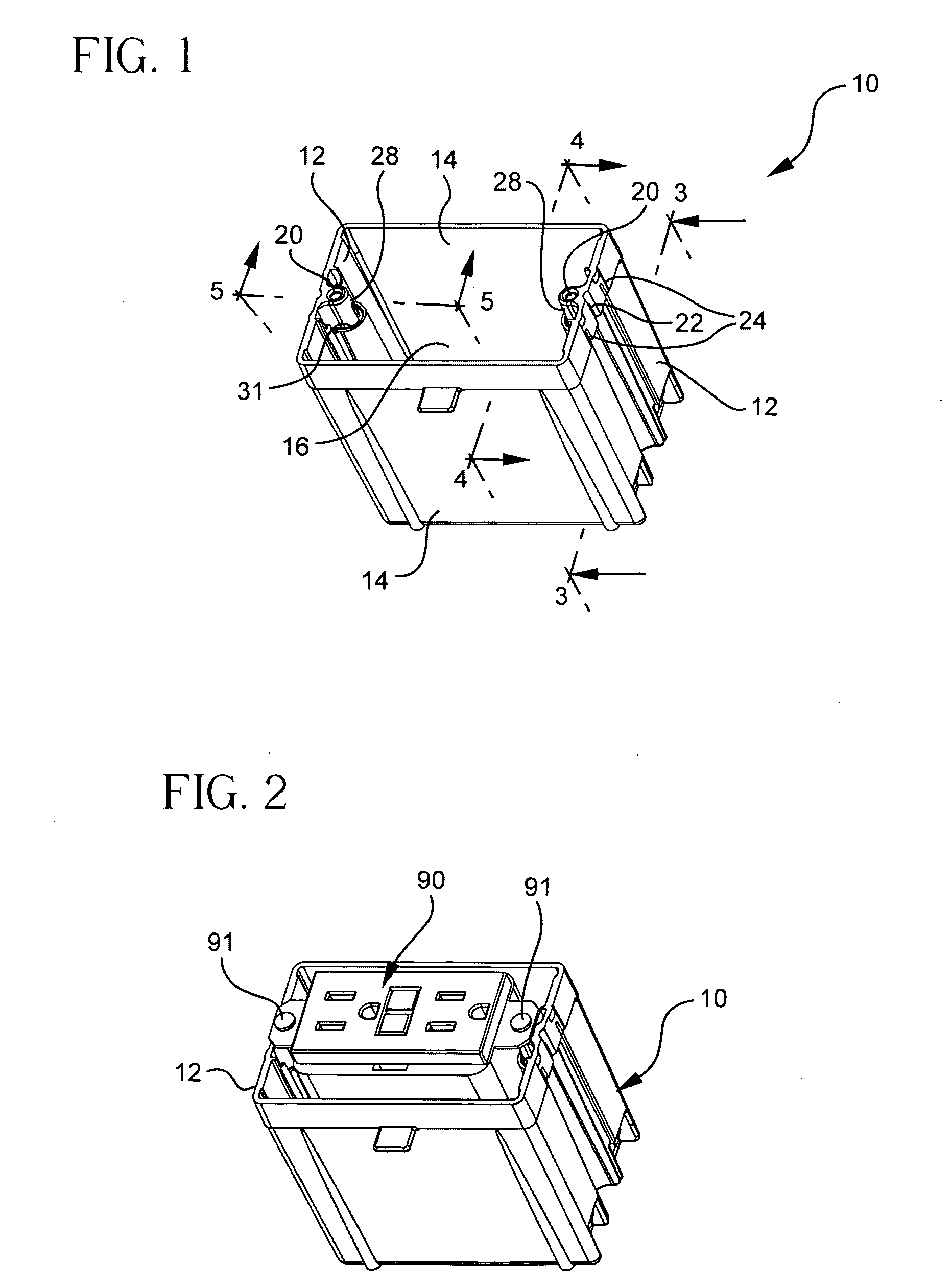

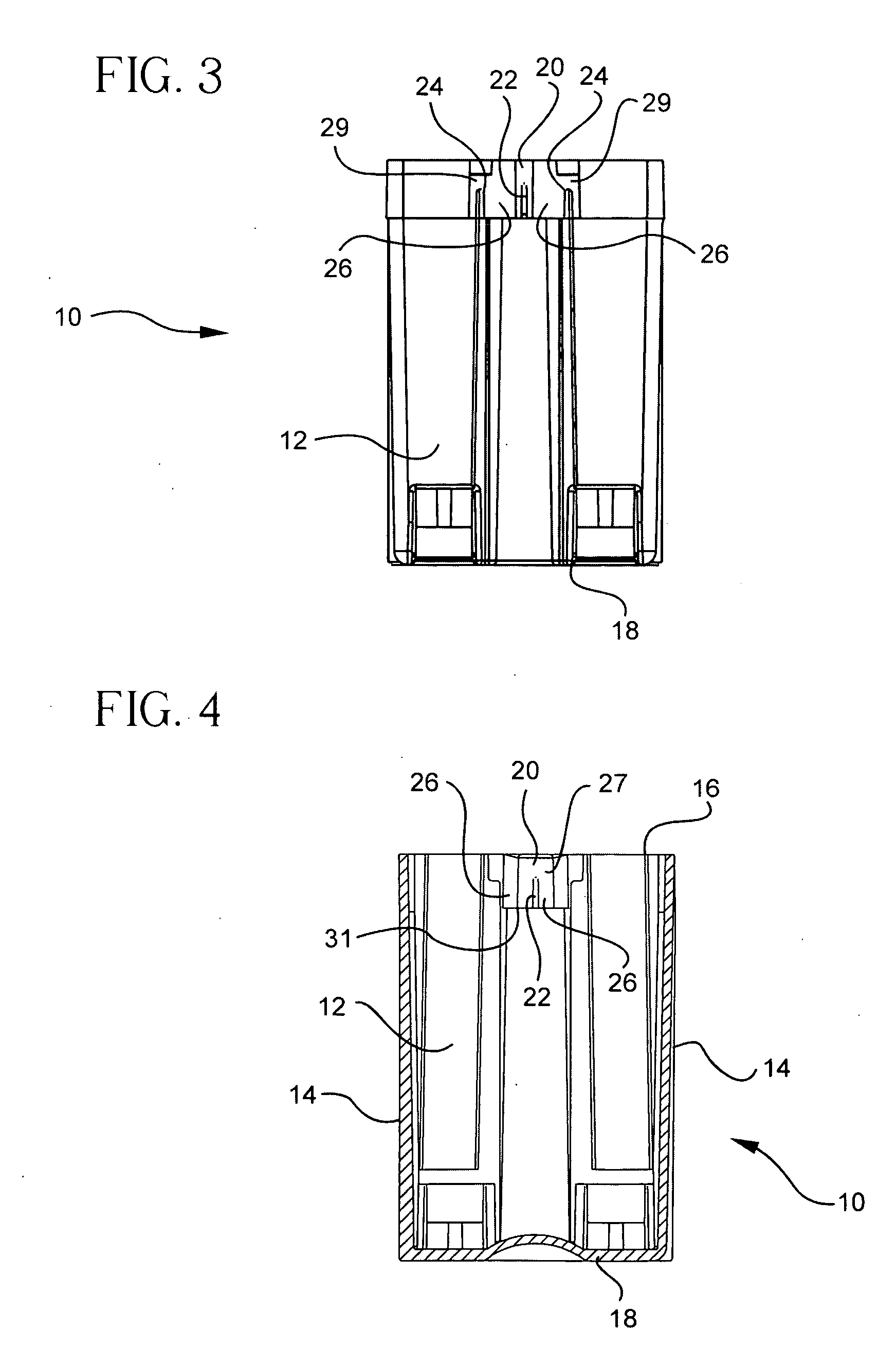

[0029] The present invention is an electrical junction box with fast set screw mounting sockets for installing electrical devices in the box. The fast set screw mounting sockets allow the user to install an electrical device, such as a receptacle, into a single or multi gang box without having to manually thread the mounting screws into the box or use power tools. The electrical junction box of the present invention allows a device to be installed by simply placing the device in the box, aligning the mounting apertures of the device with the fast set screw mounting sockets of the box and pushing the mounting screws into the sockets. Optionally, the user can still turn the mounting screws a couple of twists to engage the threads of the screw with the interior walls of the socket, if mounting the traditional way is desired.

[0030] The fast set screw mounting sockets have a first end, which corresponds to the front opening of the box, a second or rear end and a mid-region, which is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com