Crank handle for spinning reel

a spinning reel and crank handle technology, applied in the field of fishing tackles, can solve problems such as the unstable crank handle b>3/b>, and achieve the effect of high stability and durabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

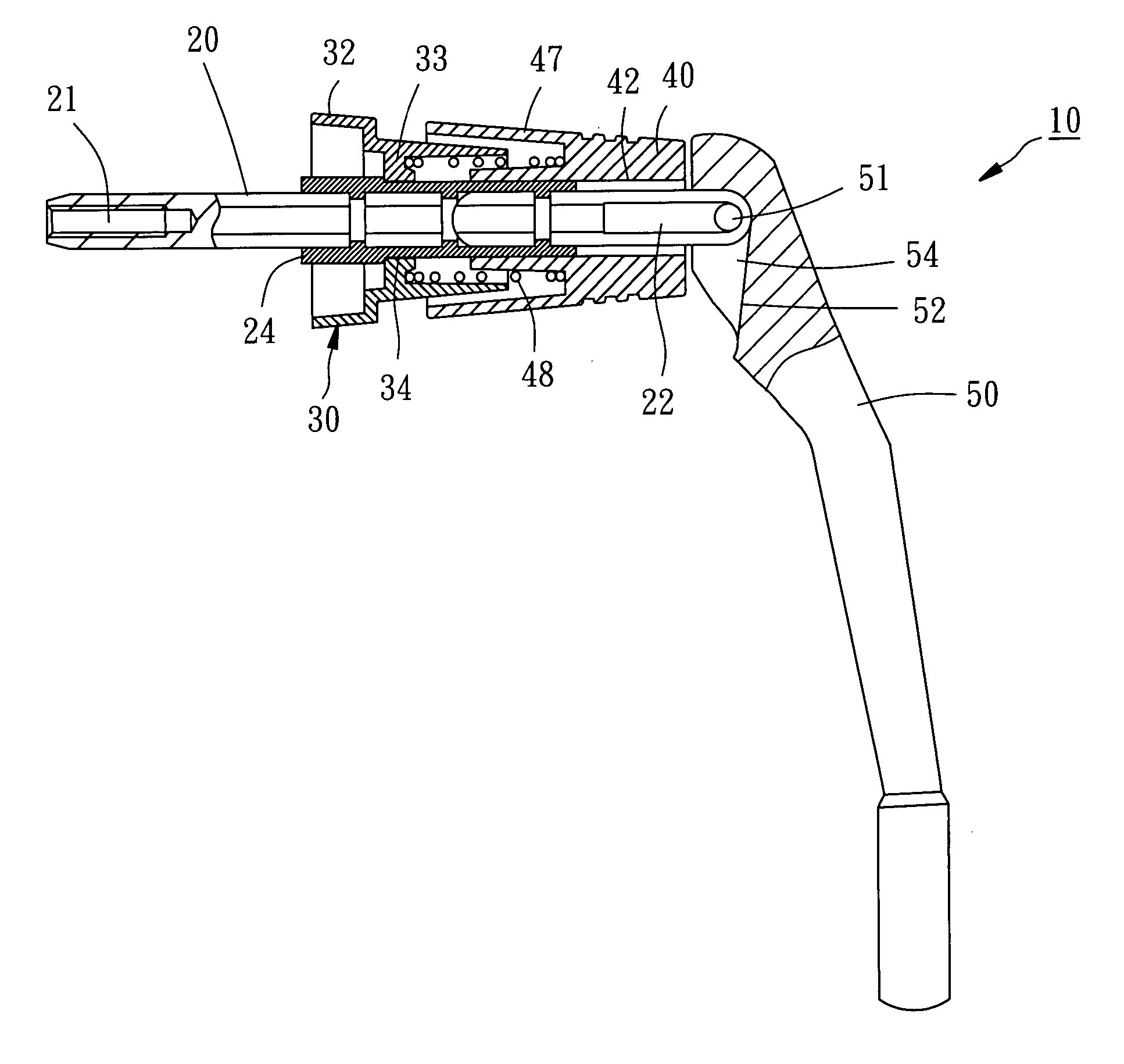

[0019] Referring to FIGS. 4-7, a crank handle 10 for a spinning reel in accordance with the first embodiment of the present invention is shown comprised of an axle 20, a base 30, a bush 24, a retaining member 40, a spring 48, and a handle 50.

[0020] The axle 20 has a screw hole 21 axially provided at one end thereof for fastening to the spinning reel with a screw (not shown), and two cut faces 22 longitudinally disposed at the other end thereof at two opposite sides. The axle 20 is a hexagonal rod member for engagement with other gear (not shown) in the spinning reel.

[0021] The base 30 comprises a tubular shell 32, a partition wall 33 transversely provided inside the tubular shell 32, and a through hole 34 provided at the partition wall 33 through which the axle 20 is inserted.

[0022] The bush 24 is sleeved onto the axle 20 and inserted into the through hole 34 of the base 30. The bush 24 is fixedly fastened to the axle 20 so that the bush 24 and the axle 20 can be rotated relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com