Cleaning tool and method of manufacturing cleaning part thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

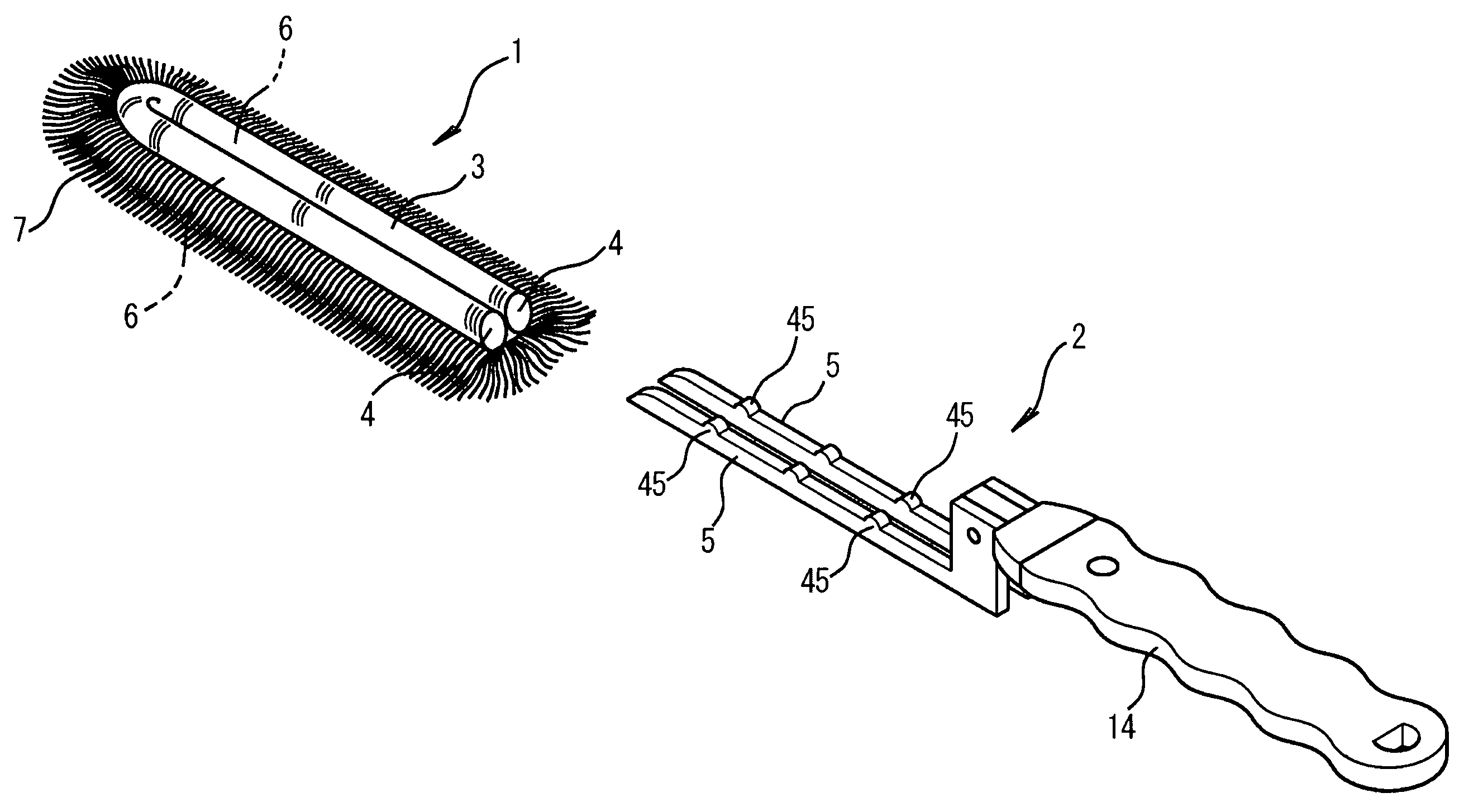

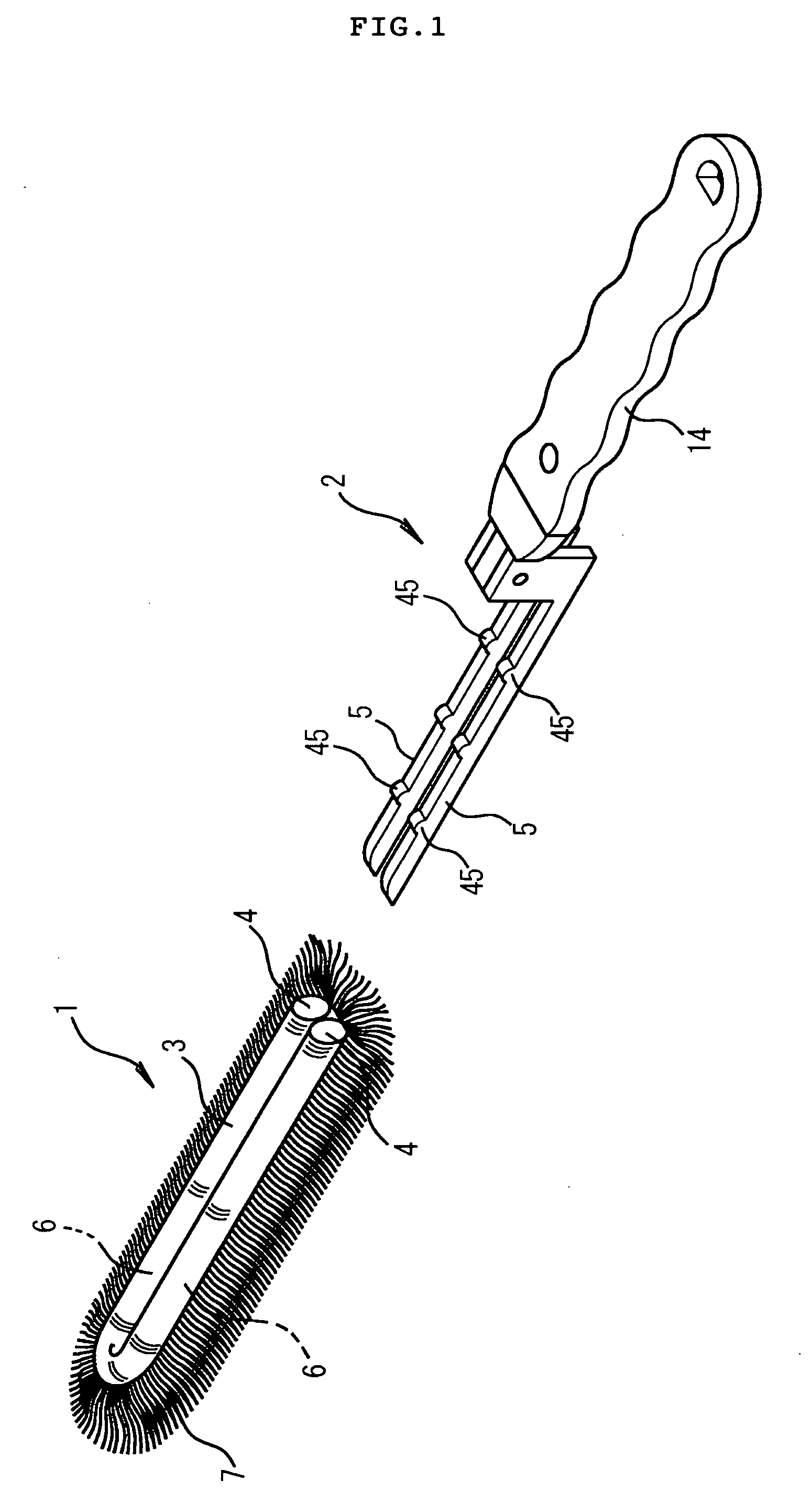

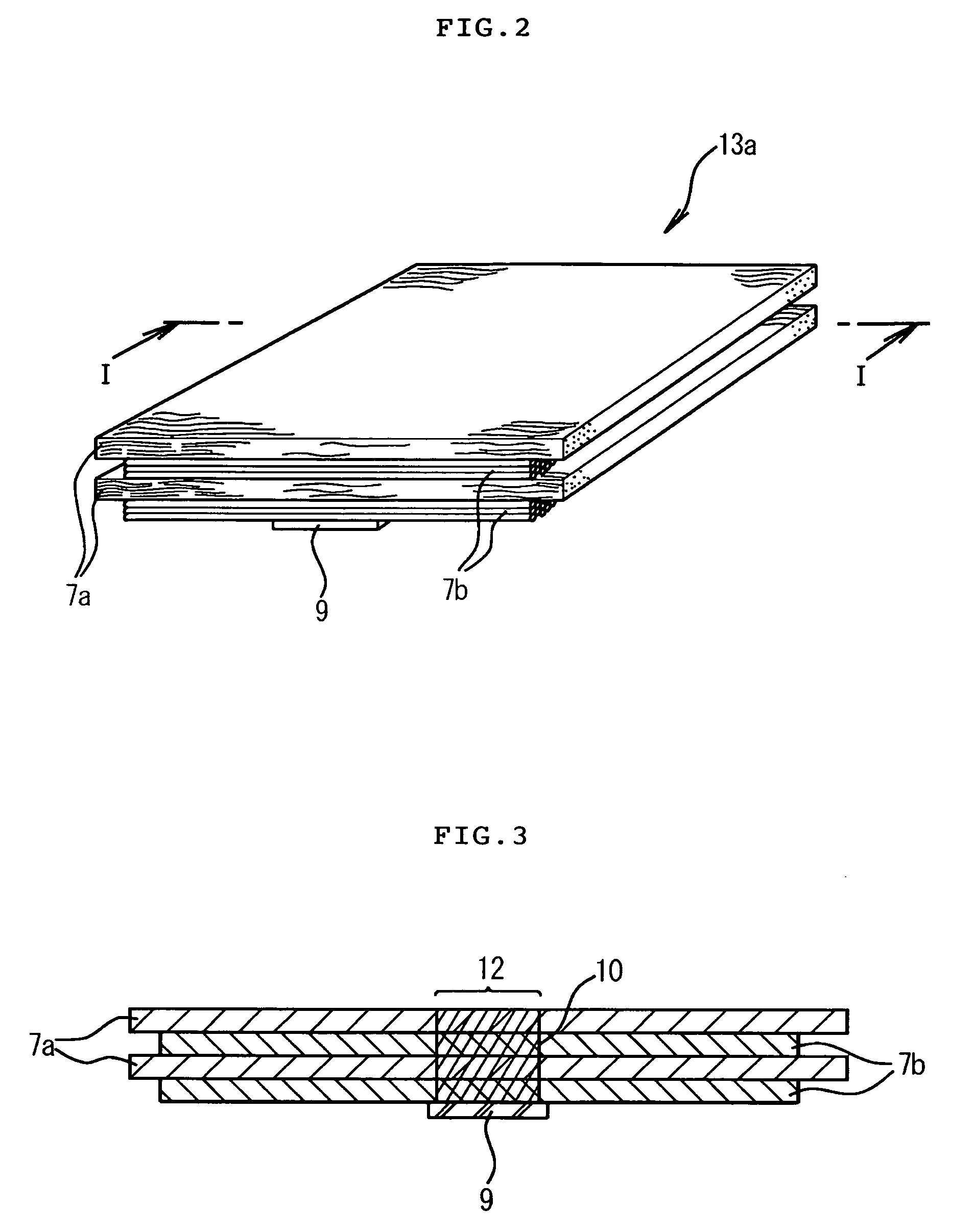

[0072] The cleaning tool of the present invention comprises a cleaning component and a handle component, wherein the cleaning component is designed such that a sheet-like fiber bundle and a sheet are joined to produce a sheet laminate in which a joining portion is formed, this sheet laminate is bent along the joining portion to form a bulky component formation portion, the sheet laminate in which said bulky component formation portion has been formed is bent so that bulky component formation portions are across from each other, and integrated such that the contact surfaces of the opposing sheet-like fiber bundles are joined together, and support rods of the handle component are inserted into a handle insertion component formed inside the bulky component formation portion and having handle insertion openings made at one end of the bulky component formation portions.

[0073] Examples of the sheet used in the cleaning component include paper, synthetic resin sheets, and nonwoven cloth, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com