Machine for filling and closing two-piece capsules

a two-piece capsule and machine technology, applied in the direction of liquid materials, packaging goods, transportation and packaging, etc., can solve the problems of not being sufficiently improved to provide a higher product yield, and still residues in and around the cap and bottom receptacles that may have an adverse effect, so as to increase the production of product-filled capsules, increase the cleaning activity of receptacles, and reduce damage. the effect of product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

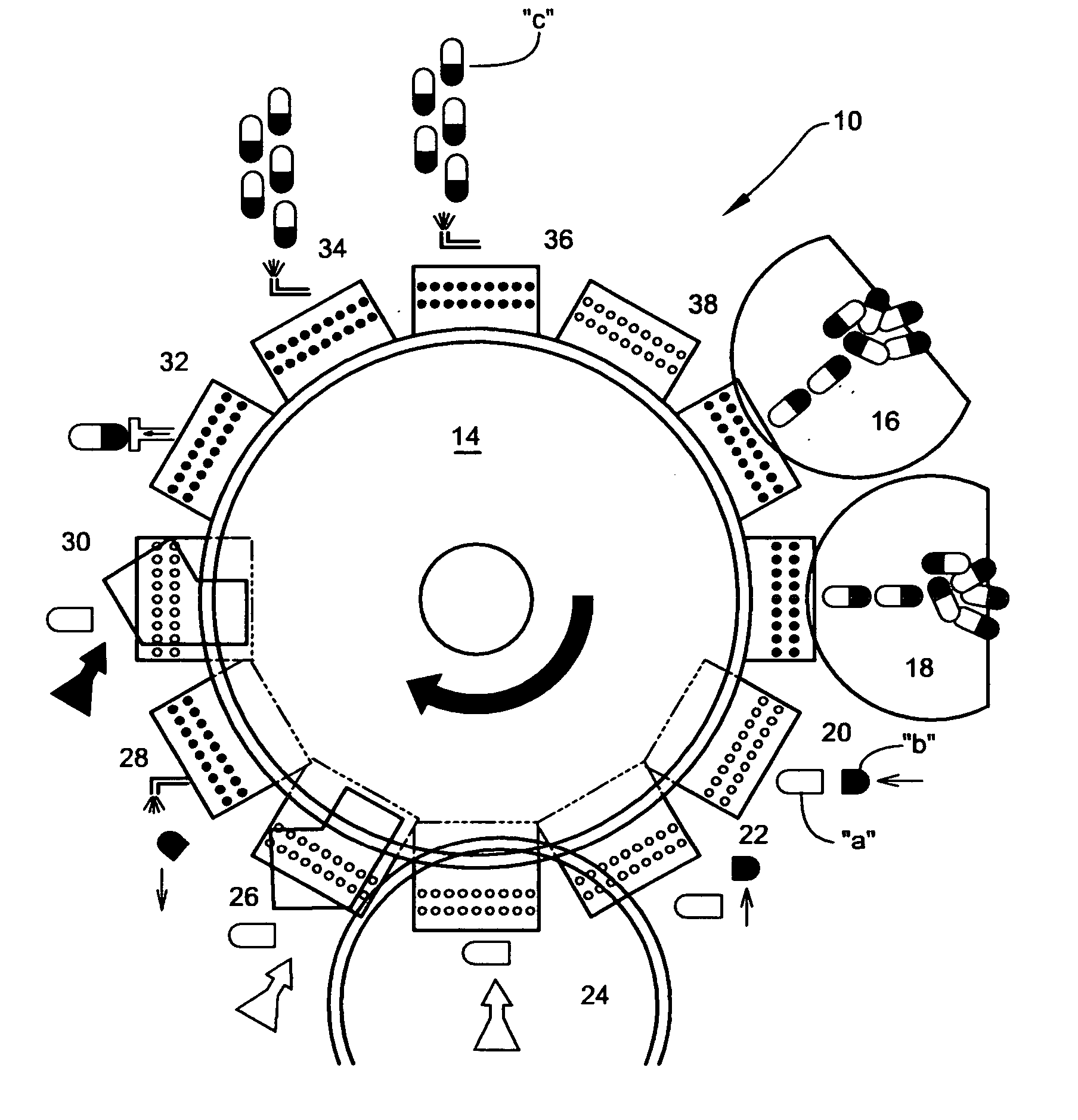

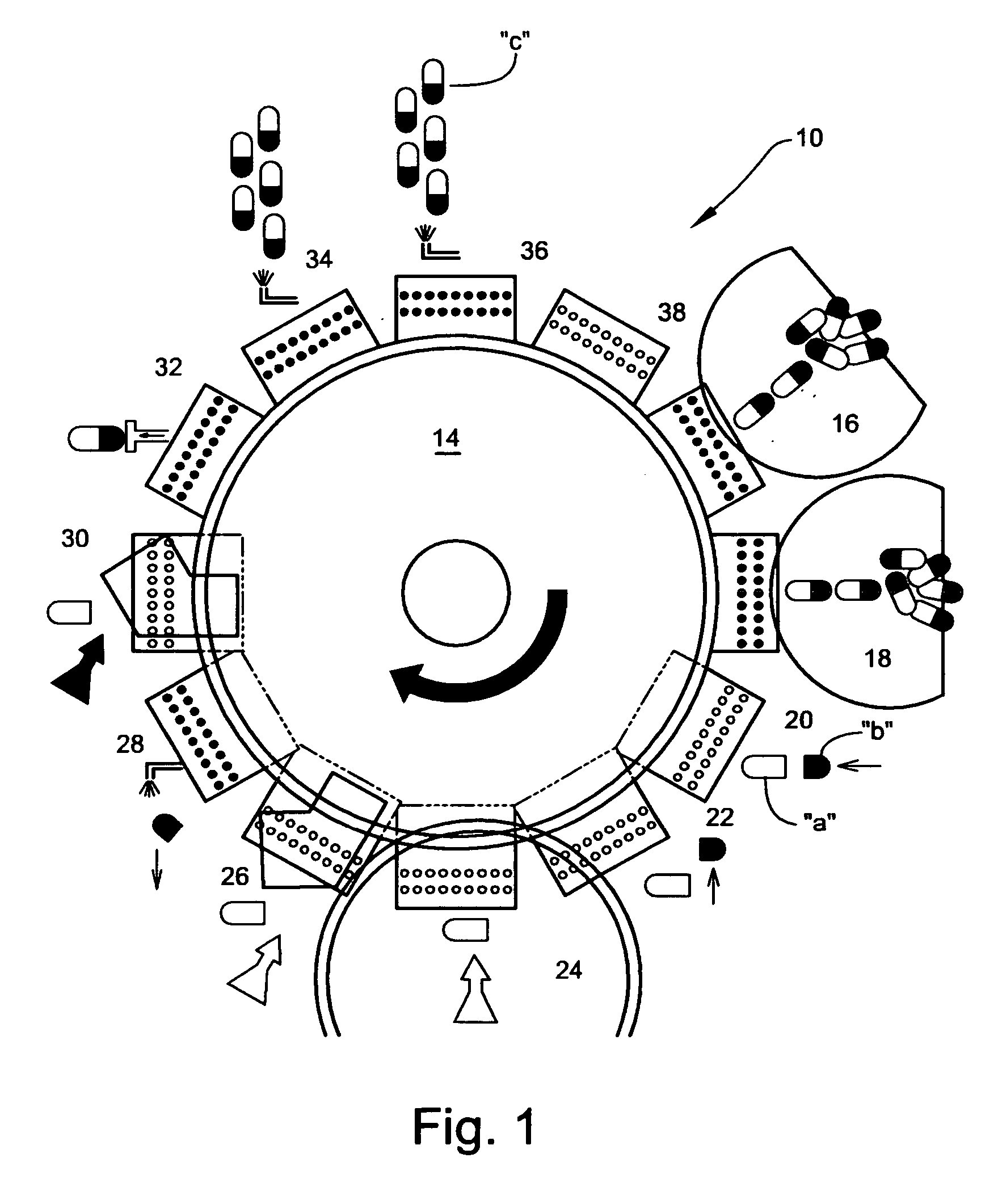

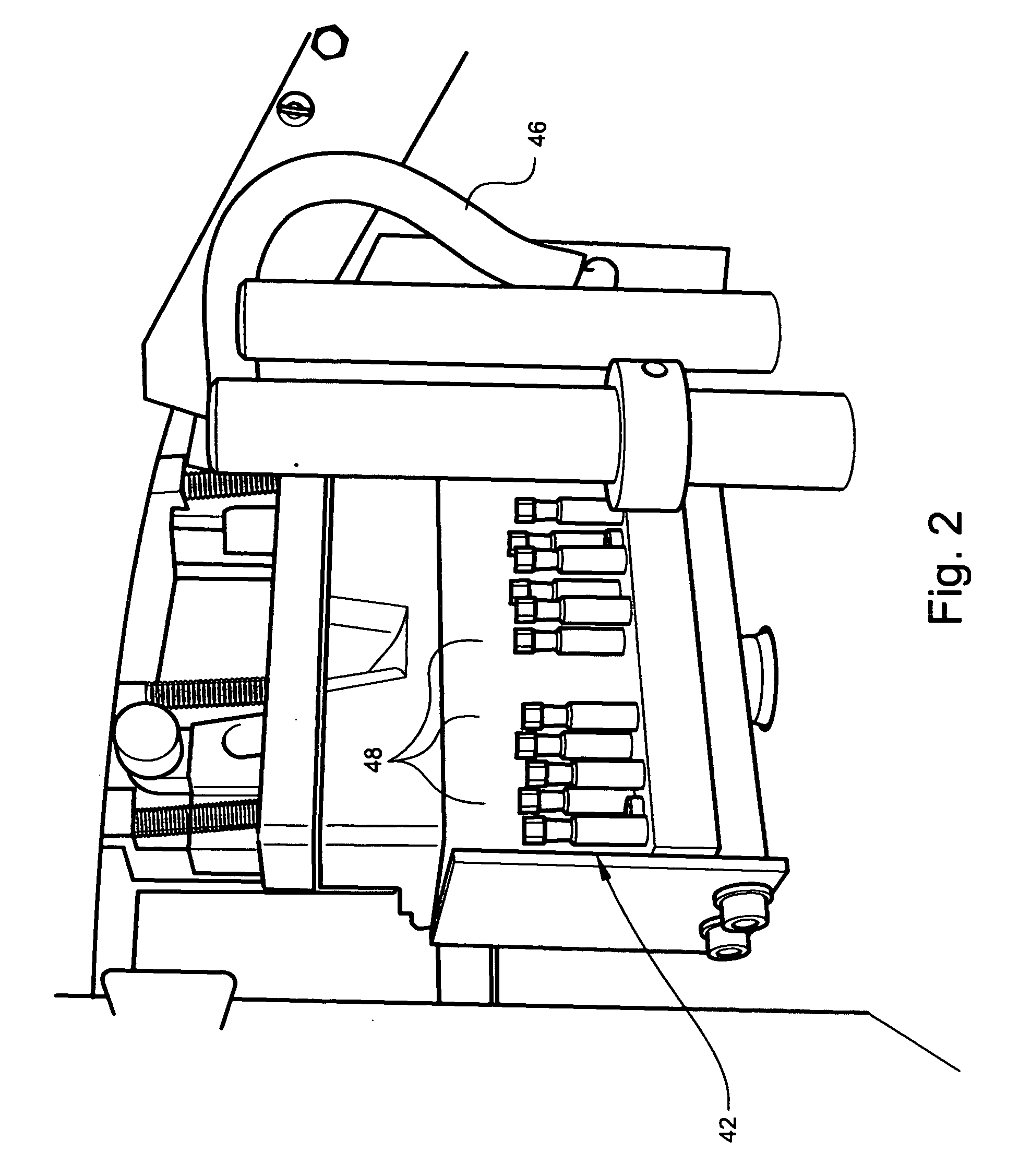

[0023] Referring now to the drawings and particularly FIG. 1, a machine shown generally as 10, for filling and closing capsules “c” made up of a capsule bottom “a” and a cap “b” mounted on the capsule, has a 12 piece feed wheel 14 rotated in increments about a vertical axis at stations 16, 18, 20, 22, 24, 26, 28, 30, 32, 34, 36 and 38. The individual segment blocks are arranged along the path of revolution as shown. At station 16, the empty capsules c to be filled are placed in random order and then delivered straightened and in order to the feed wheel 14. At station 18, the caps b are then separated from the capsule bottoms a, and both parts are checked by a checking device 40 for their presence and intactness. At station 20, the caps b are separated from the capsule bottoms so that at stations 22, 24 and 26 product can be placed in the capsule bottom a. At station 28, any capsule bottoms a and caps b that have been found defective are expelled. At station 30, the caps b are pushed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com