Container for Transporting Temperature Controlled Items

a technology for temperature control items and containers, applied in the direction of packaging foodstuffs, domestic cooling devices, packaged goods, etc., can solve the problems of not meeting the need for documented temperature monitoring, unable to transport biological materials such as blood and blood products in a timely manner, and significant limitations of coolers used to cool biological and related materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The term “temperature controlled item” is intended to cover any product that must be kept within predetermined temperature ranges during transport and is not intended to be interpreted in a narrow or limiting manner.

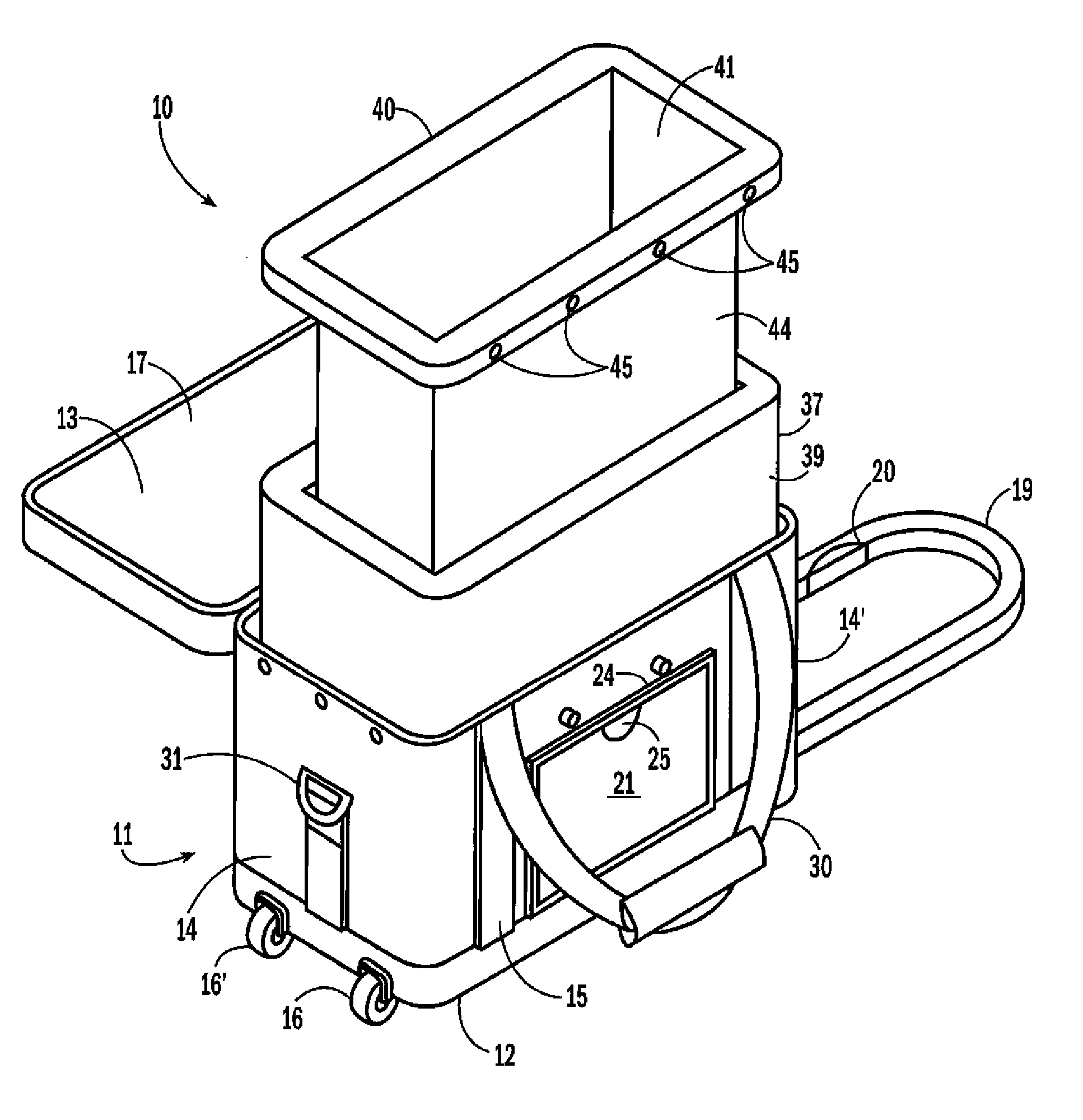

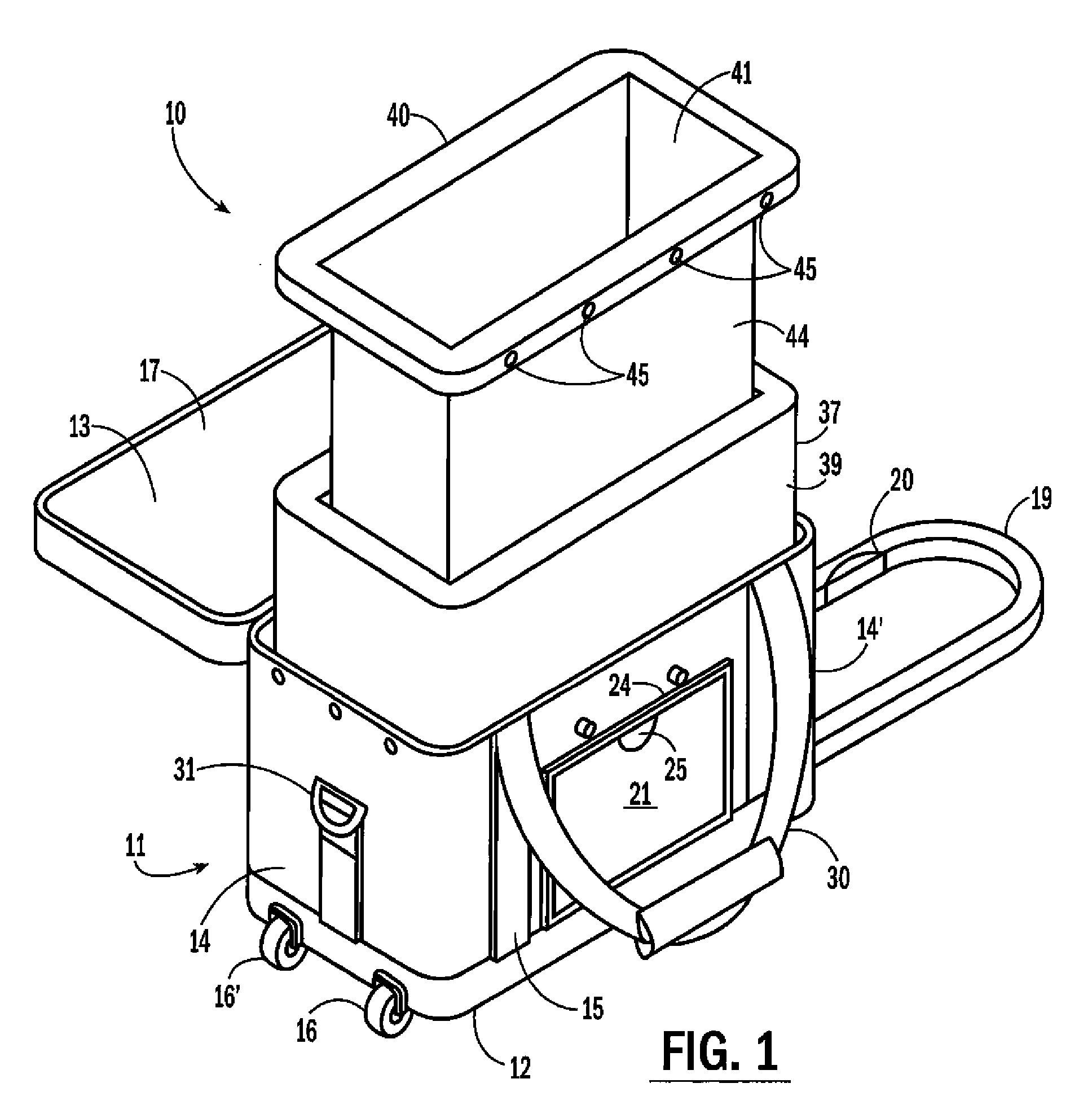

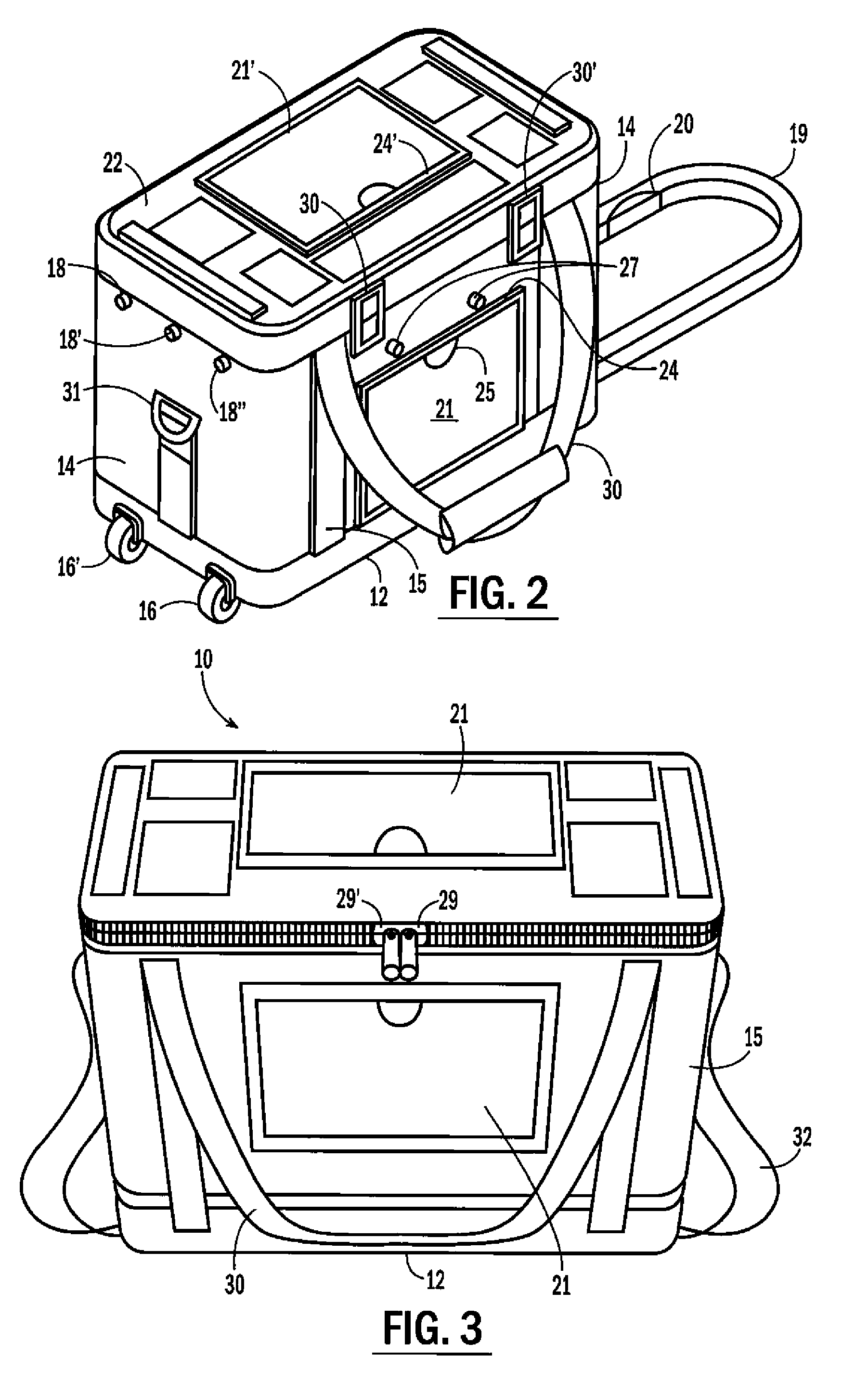

[0039] By reference to the exemplary drawings in detail wherein like numerals indicate like elements throughout the various views, there is shown in FIG. 1 an exemplary container 10 for transporting temperature controlled items in accordance with the invention.

[0040] The container 10 can include an outer case 11 that may be formed from soft, flexible, lightweight material such as ballistic nylon, vinyl or canvas, or a hard rigid material for more durability, or any other suitable materials generally known and used by persons skilled in the art. The outer case 11 is preferably made of waterproof, stain resistant, rustproof material, which can be easily cleaned. The container 10 may be made in different sizes depending on the number of blood or blood product units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com