Method for increasing the strength of a volume of soil, particularly for containing and supporting excavation faces

a technology of soil and strength, applied in the direction of bulkheads/piles, foundation engineering, construction, etc., can solve the problems of unstable slopes that are not necessarily steeply inclined, inducing horizontal displacements that are dangerous for buildings arranged, and a long time of draining conditions, etc., to achieve the effect of increasing the resistance to all the various stresses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

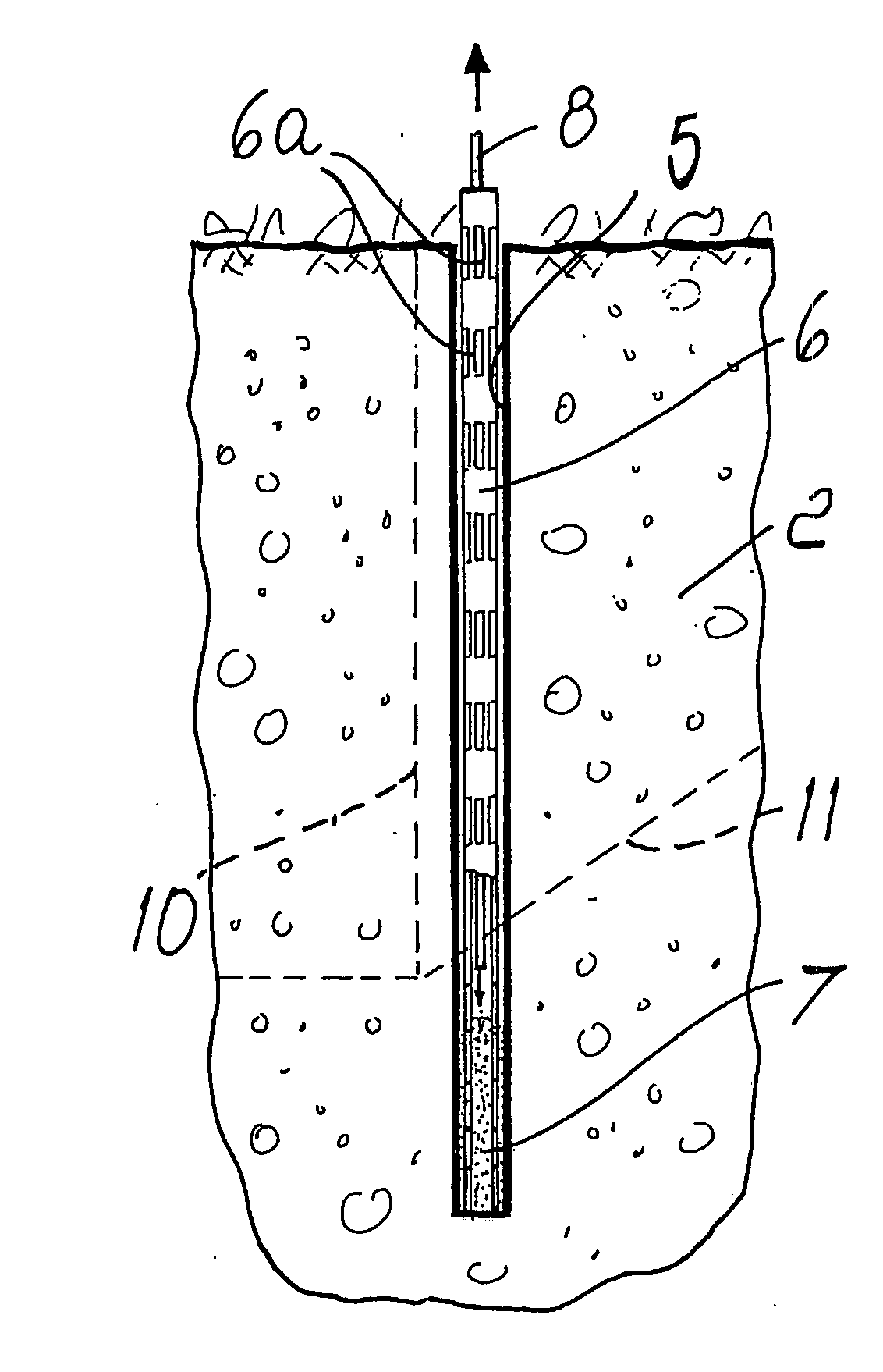

[0128] If the strength and composition characteristics of the soil in the natural state whose resistance to all the various stresses is to be increased are such as to allow the injected synthetic substance, once the chemical expansion reaction is completed, to have a high final density (approximately 250-400 Kg / m3), such as to ensure high resistances to shear stresses (and therefore high adhesion to the reinforcement structure), the method according to the invention can be performed in a simplified form, or second embodiment, by avoiding the preventive consolidation step and performing only the reinforcement step. In this case, the synthetic substance injected into the reinforcement holes 5 is chosen so as to achieve simultaneously a consolidation of the soil that surrounds the reinforcement holes 5 and an adequate locking of the reinforcement elements in the reinforcement holes 5.

[0129] In this case, the synthetic substance that is injected into the reinforcement holes 5, as a cons...

first embodiment

[0131] In the simplified embodiment of the method according to the invention, owing to the fact that the strength and composition characteristics of the soil in the natural state to be strengthened are such as to allow the injected synthetic substance, once the chemical expansion reaction has ended, to have a high final density (generally comprised between 250 Kg / m3 and 400 Kg / m3), such as to ensure high shear strengths (and therefore high resistance to extraction of the reinforcement elements), the synthetic substance that is used may also be the consolidating synthetic substance that can be used in the consolidation step described with reference to the method according to the invention.

[0132] In the presence of a high but not sufficient degree of strength of the soil, the method can be performed in a third embodiment, which is intermediate with respect to the two previously described embodiments and according to which the injection step and the reinforcement step are performed sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com