Lightweight Wall Structure For Building Construction

a technology for building construction and light weight, applied in the direction of walls, constructions, building material handling, etc., can solve the problem of labor-intensive task of laying blocks to create walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

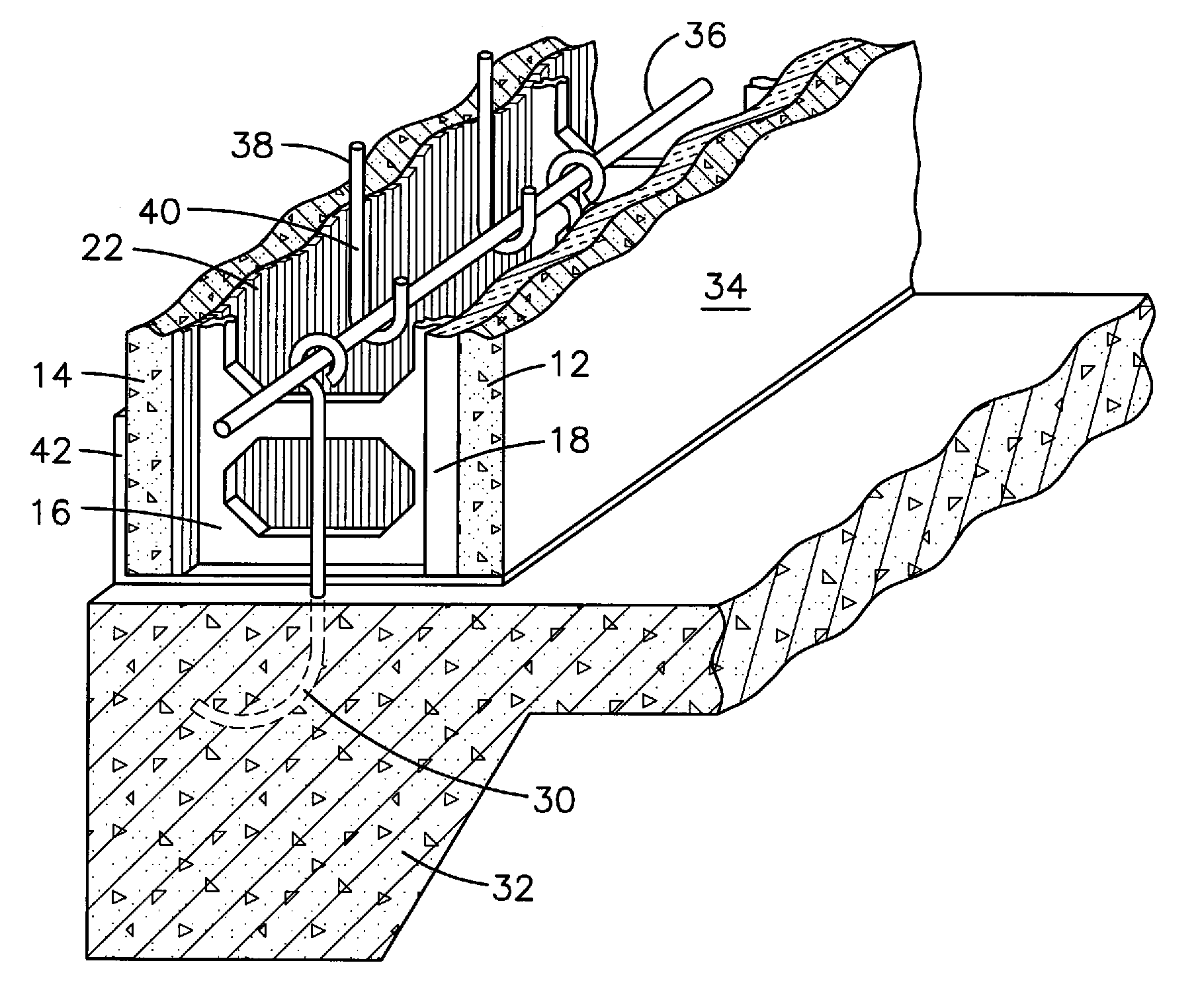

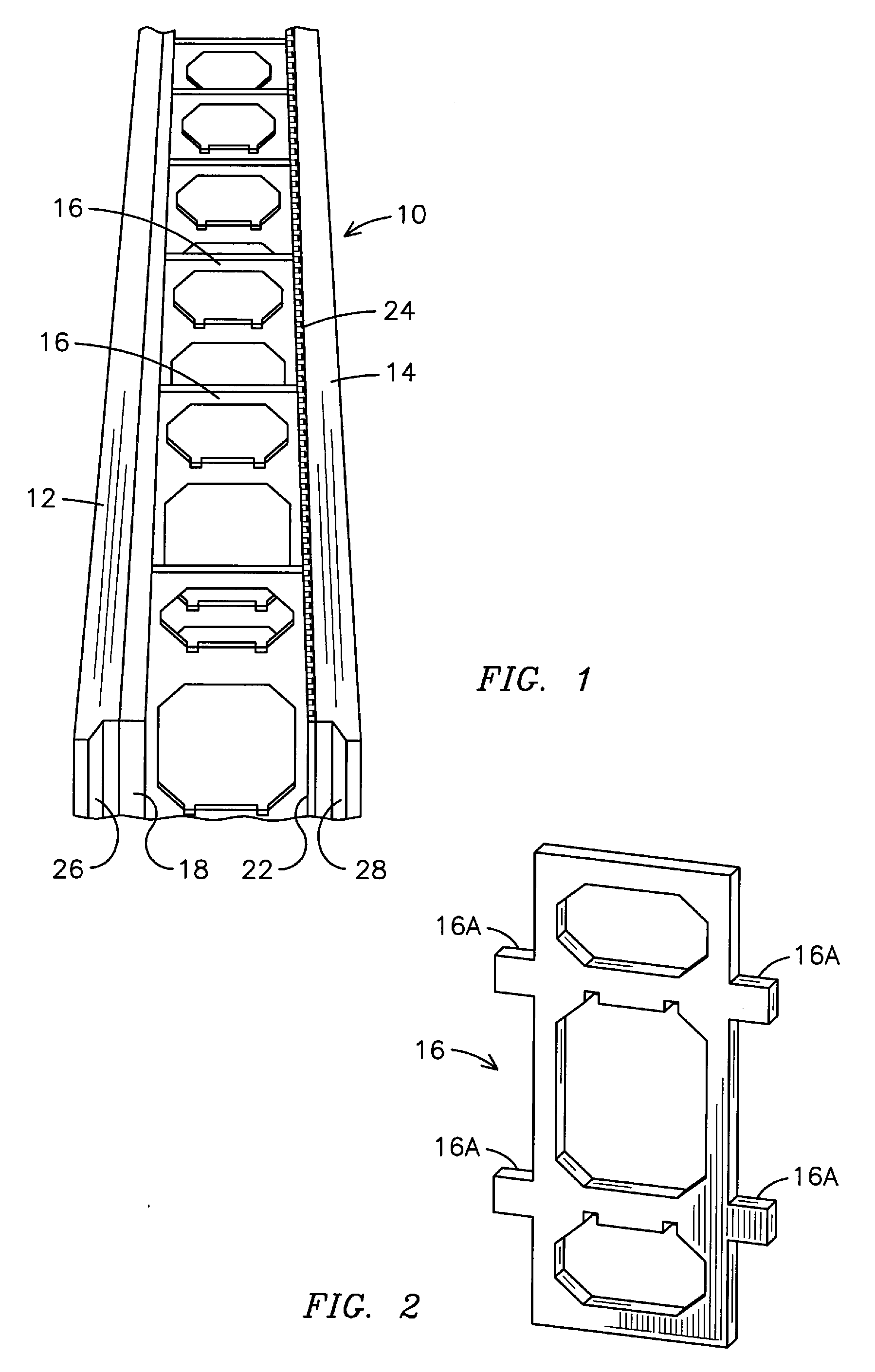

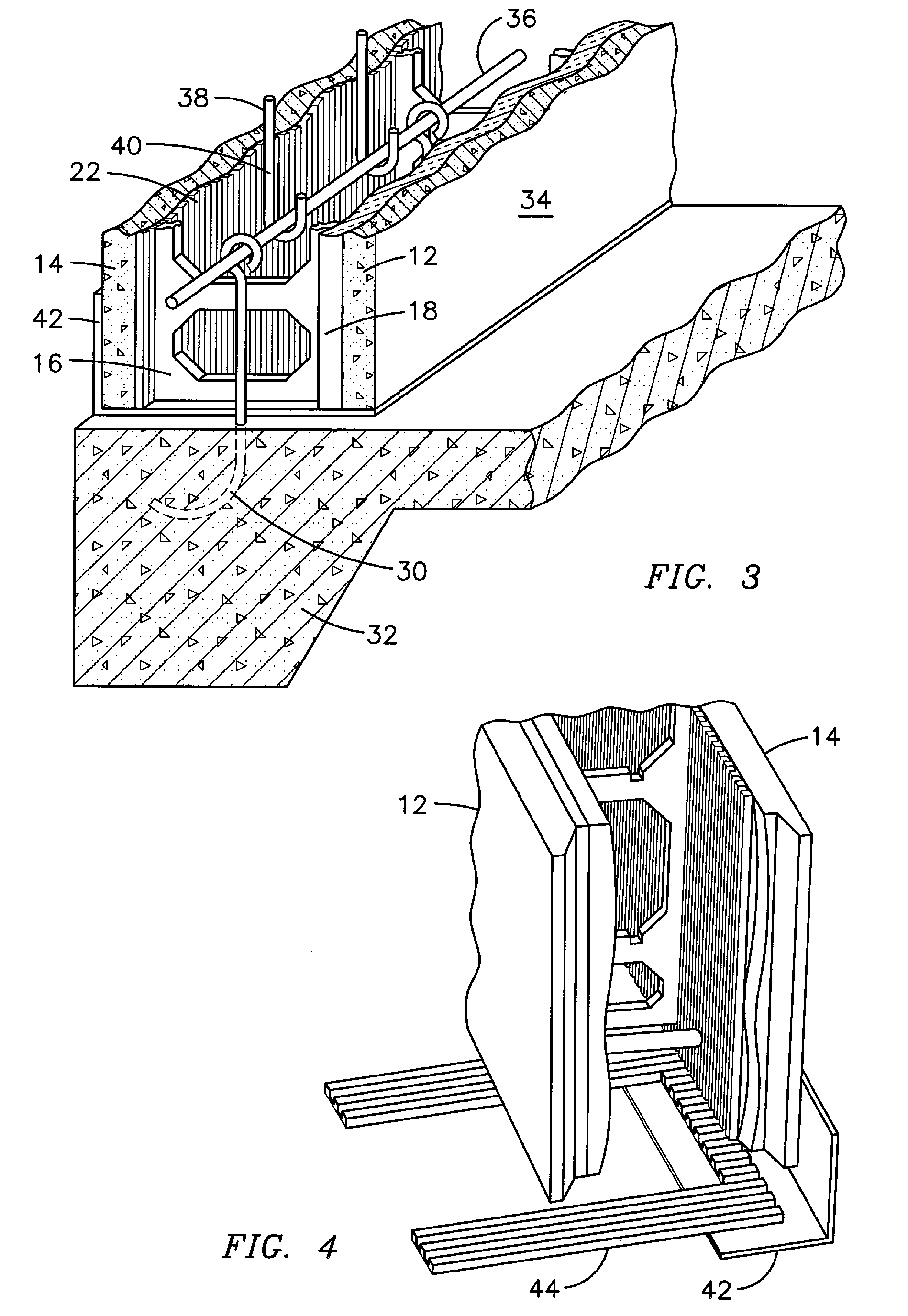

[0028] Applicant has found that a prefabricated building wall section can be constructed of lightweight concrete and designed so as to meet building code requirements and yet have a size and weight that will allow the wall sections to be assembled in situ by an individual without the need for mechanical lifting apparatus. In one form as indicated in FIG. 1, the wall section 10 is shown in an edge view having an outer panel 12 and an inner panel 14. The inner and out panels are joined by a plurality of spaced cross-members 16, each cross-member having portions extending into the panels 12 and 14. FIG. 2 is a front view of one of the cross-members 16 showing the extending portions 16A that are embedded in the panels 12,14. Each of the panels 12 and 14 are formed from poured lightweight concrete, such as, for example, a Forton® or a Donalite® concrete mix. The cross-members 16 may be made from a fiber reinforced material or plastic material of sufficient strength to support the inner a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com