Brick wall reinforced concrete wall stud structure

A reinforced concrete and pouring concrete technology, which is applied in building construction, building maintenance, construction, etc., can solve problems such as failure to produce occlusal effect and unsatisfactory reinforcement effect, so as to improve overall stability and local compressive bearing capacity, The effect of small member cross-sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

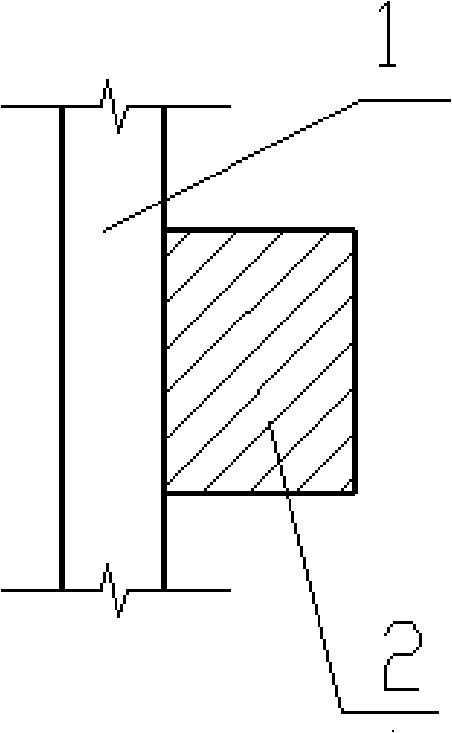

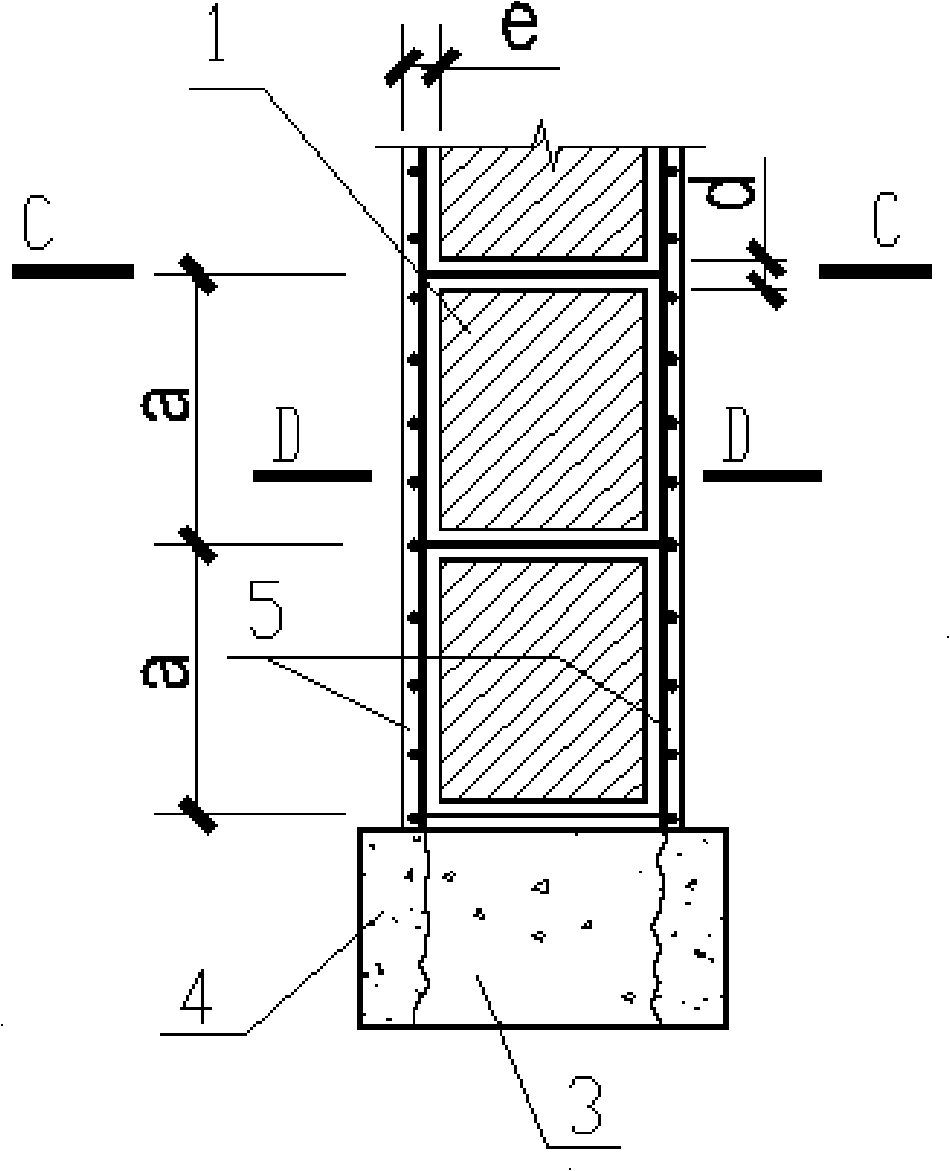

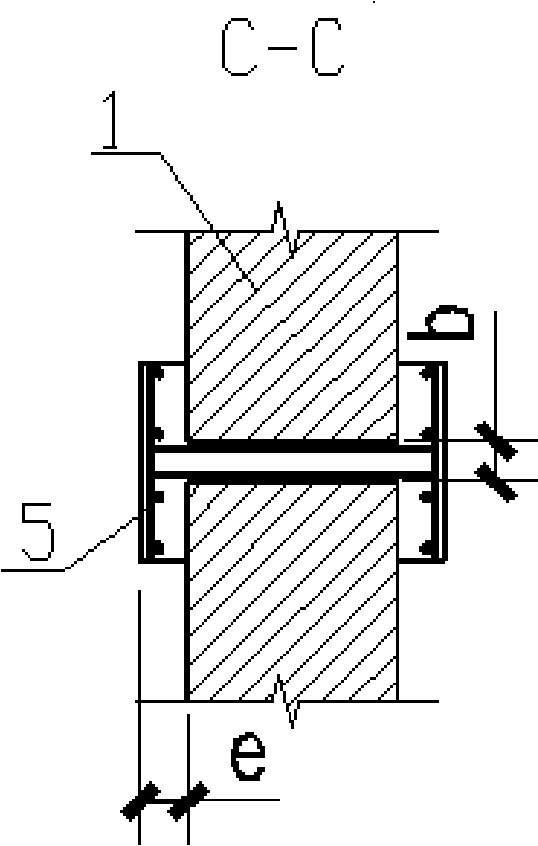

[0015] Embodiment of the present invention: when adopting the inventive method to set up reinforced concrete wall column, can carry out as follows:

[0016] First, determine the area, location and quantity of reinforced concrete pilasters 5 to be added through calculation, so as to ensure that the stability and local pressure of the wall can meet the requirements after the pilasters are added;

[0017] Second, pour the new plain concrete strip foundation 4 required after adding reinforced concrete pilasters. Before pouring, the edges of the plain concrete strip foundation 3 of the original brick wall 1 should be roughened to facilitate better connection between the new and old foundations. ;

[0018] Third, dig a hole on the existing brick wall 1. The hole should be set from the bottom of the brick wall. The center distance of the hole on the brick wall is 1m, the width is 120mm, and the height is 60mm;

[0019] Fourth, put 2 steel bars with a diameter of φ8mm in each hole, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com