Round coal yard barricade of concrete pilaster of steel plate wall

A technology of concrete and steel plate walls, applied in fences, building types, buildings, etc., can solve the problems of complex calculation of retaining walls, large consumption of steel bars, complex temperature effects, etc., and achieve the effects of convenient installation, material saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

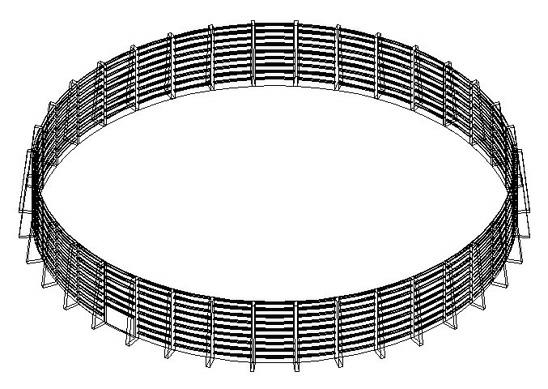

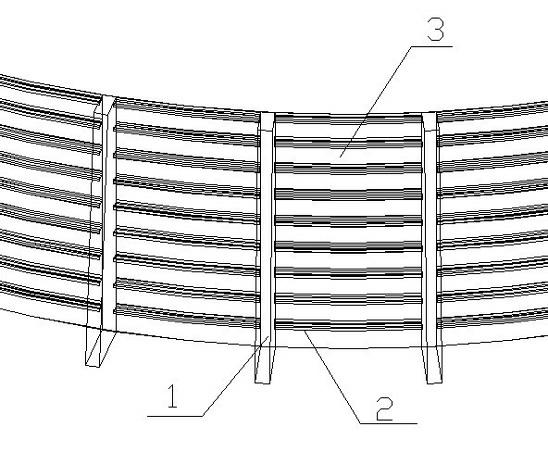

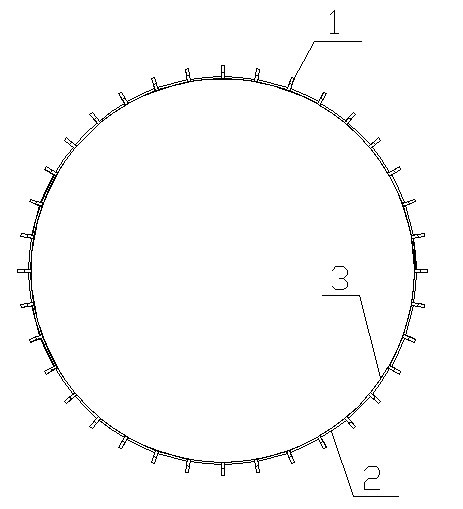

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the present invention mainly consists of buttress columns 1 made of reinforced concrete and side wall walls of steel plates 2 and steel beams 3 fixed on said buttress columns 1, and said buttress columns 1 are uniformly distributed in a ring shape , said steel beams 3 are circumferentially fixed on all buttress columns 1, and said circumferential steel beams 3 are connected with circumferentially arranged steel plates 2.

[0019] The section of the buttress column 1 shown in the figure is made into a variable-section trapezoidal section with a small top and a large bottom; the hoop steel plate 2 is connected to the hoop steel beam 3 by intermittent welding.

[0020] The buttress column 1 of the present invention is embedded with embedded parts, and the circumferential steel beam 3 is fixedly connected to the buttress column 1 through the embedded par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com