Wire sideplates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

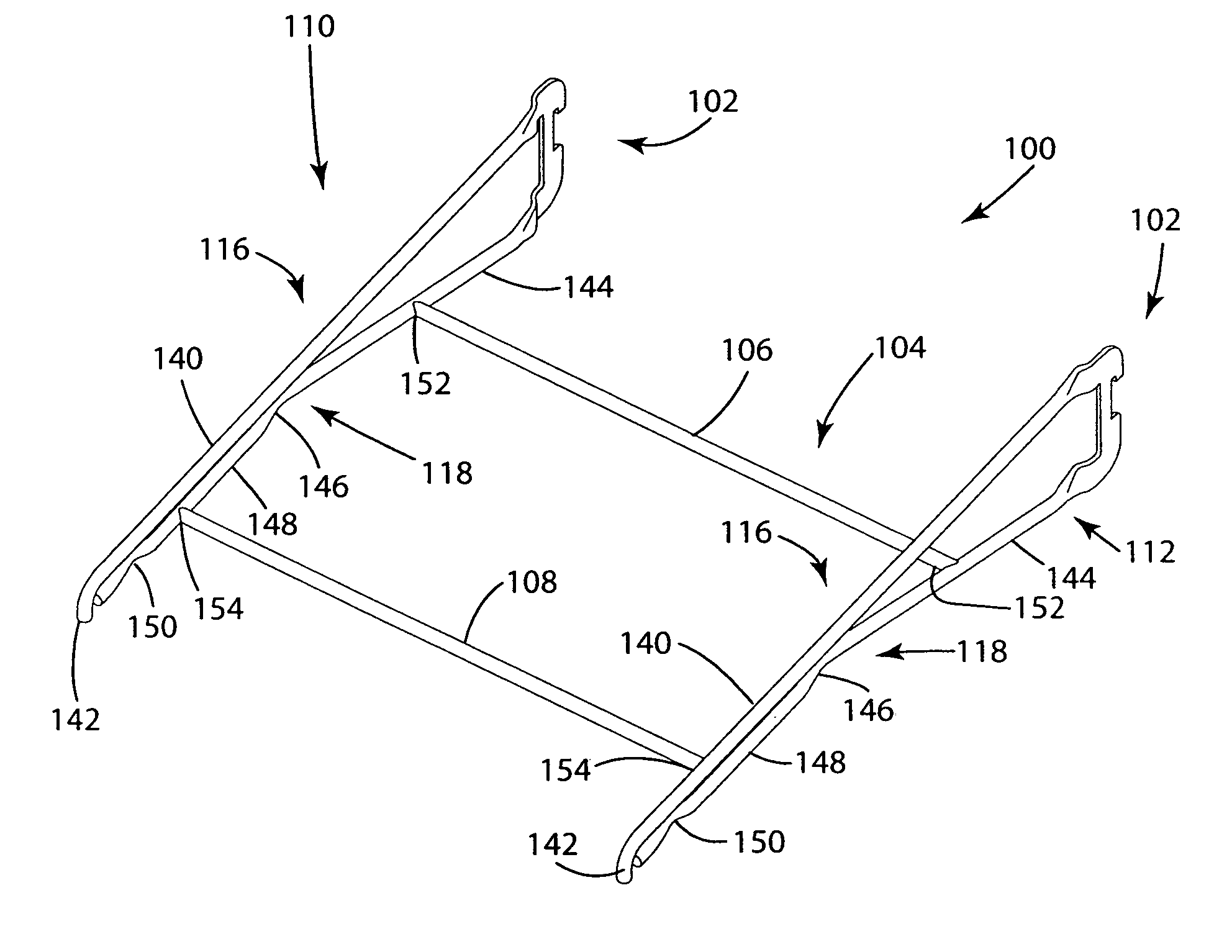

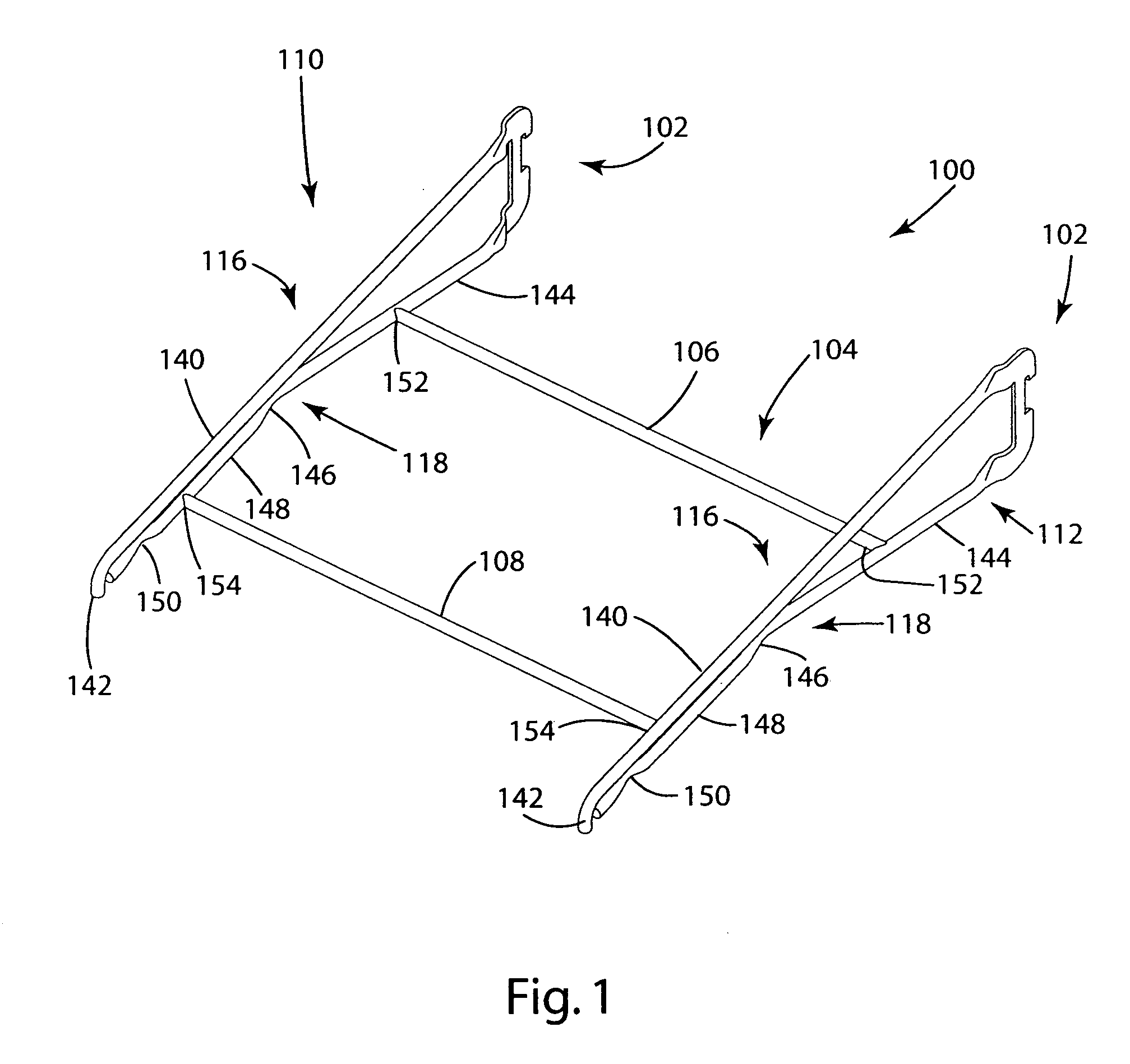

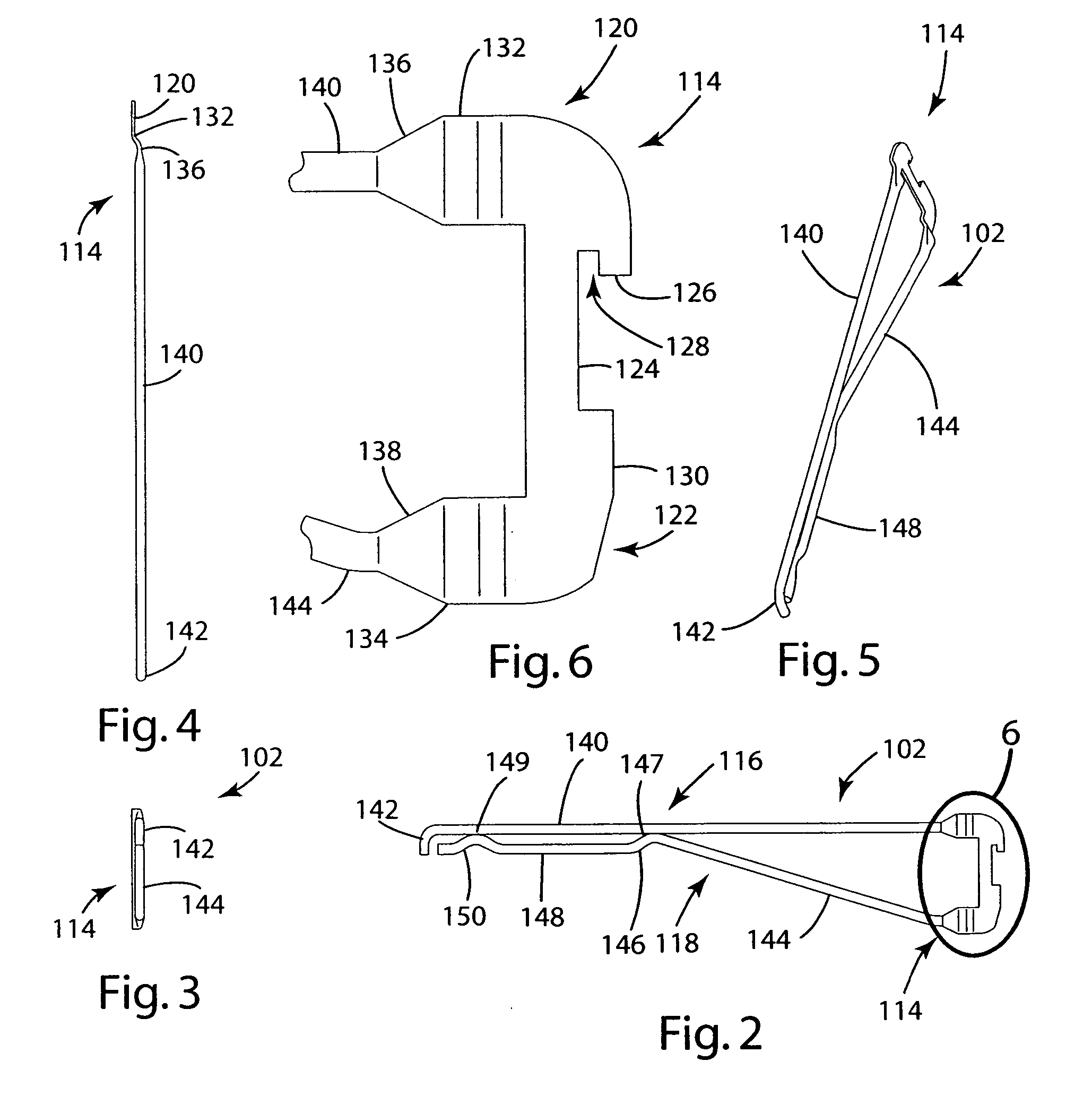

[0068] The principles of the invention are disclosed, by way of example, in certain embodiments of sideplates, sideplate frames and use of the sideplates and sideplate frames in shelving assemblies, as illustrated in FIGS. 1-39. As described in subsequent paragraphs herein, the wire sideplates in accordance with the invention comprise single pieces of wire which are formed and then pressed or stamped so as to be releasably interconnected into a number of different types of cantilever ladders which are commonly used to support shelving systems in various environments. The wire sideplates in accordance with the invention employ relatively less steel than known shelving systems which typically utilize solid pieces of stamped metal as support brackets or sideplates for shelving assemblies. Still further, wire sideplates in accordance with the invention require relatively less finishing material, in view of the reduction in surface area as compared to known support brackets or sideplates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com