MEMS sensor package leak test

a sensor and leakage test technology, applied in the field of microelectromechanical systems (mems) sensors, can solve the problems of gas leakage into or out of the sensor cavity, leakage of internal package pressure, and sensor seals often not having perfect seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

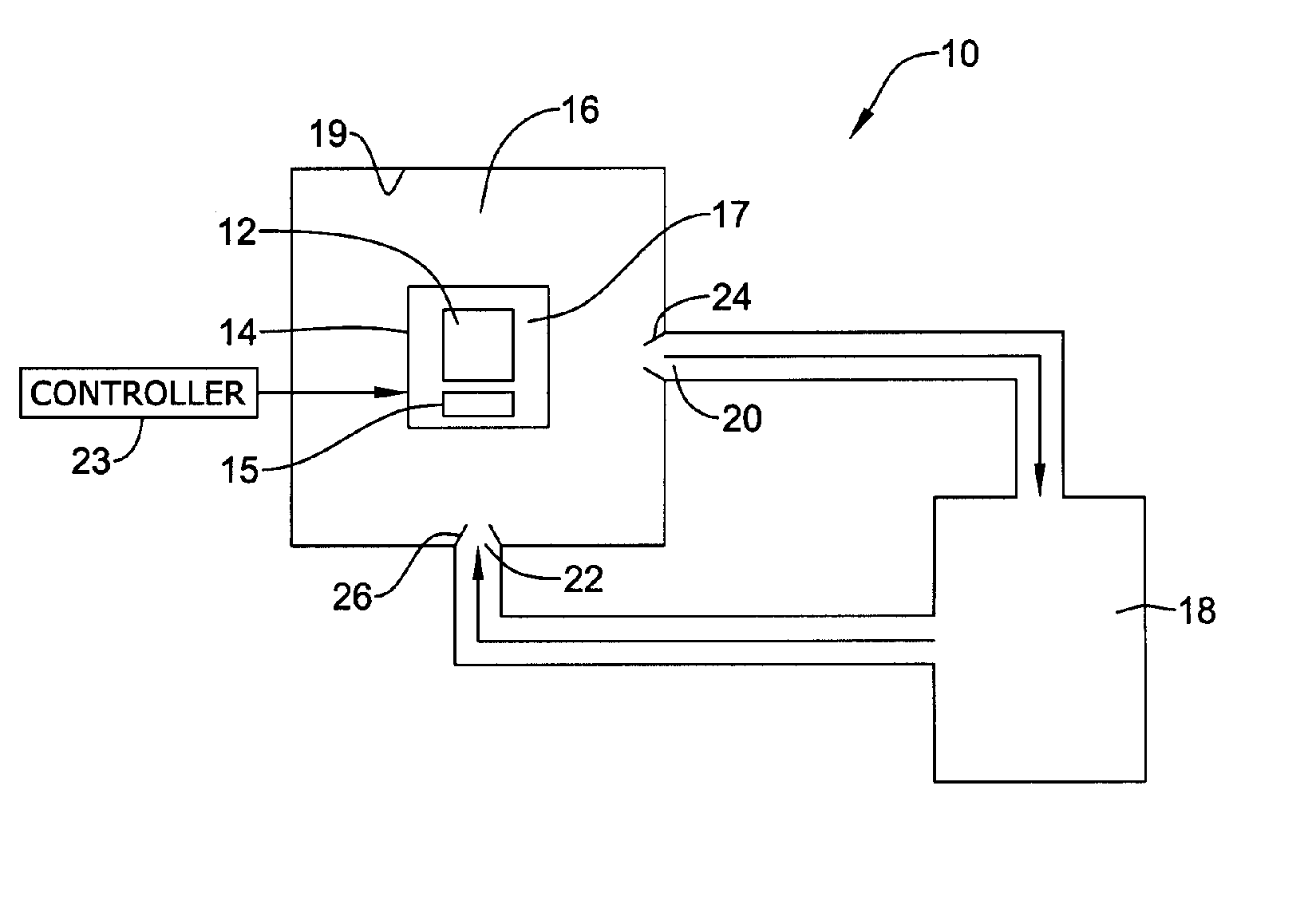

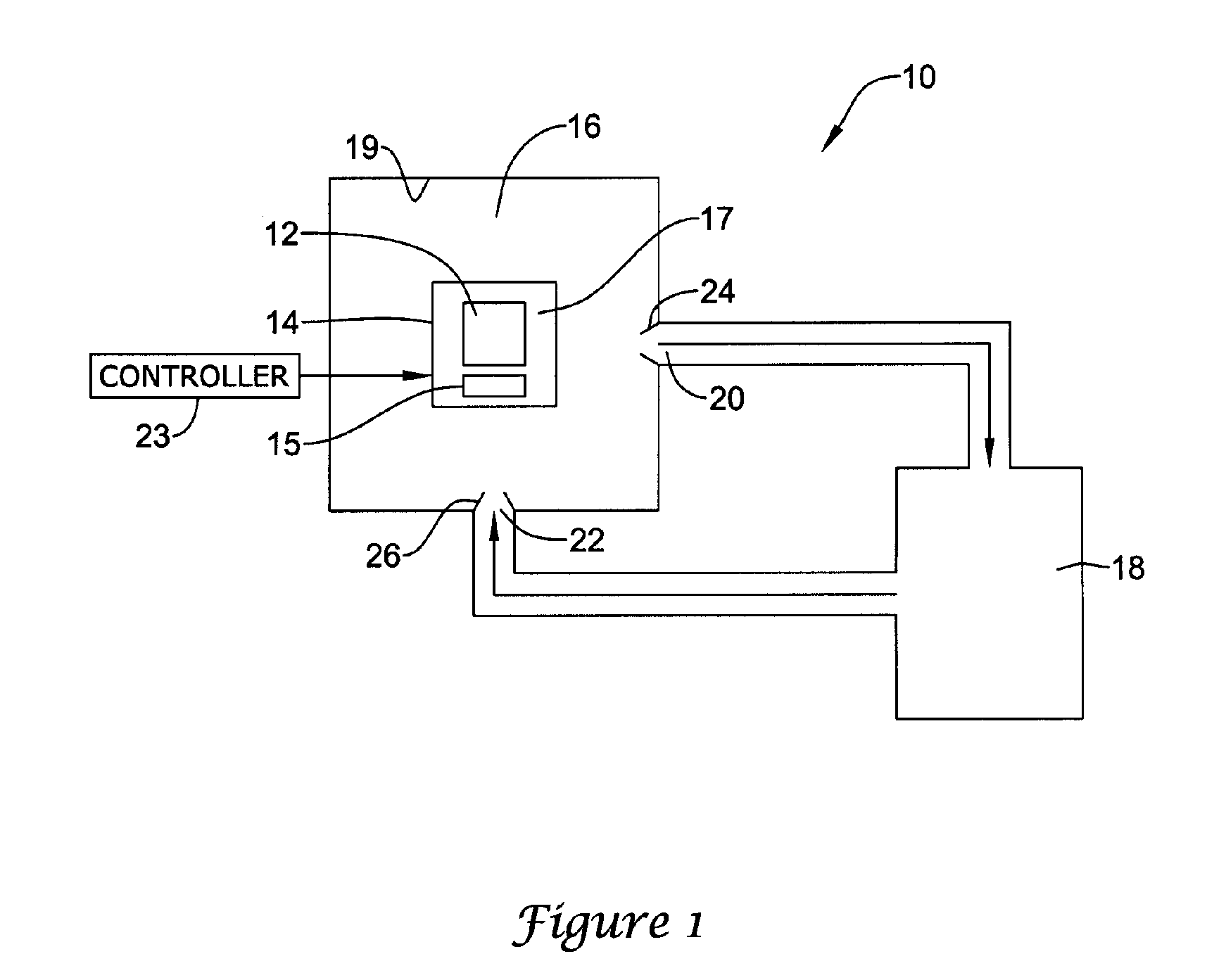

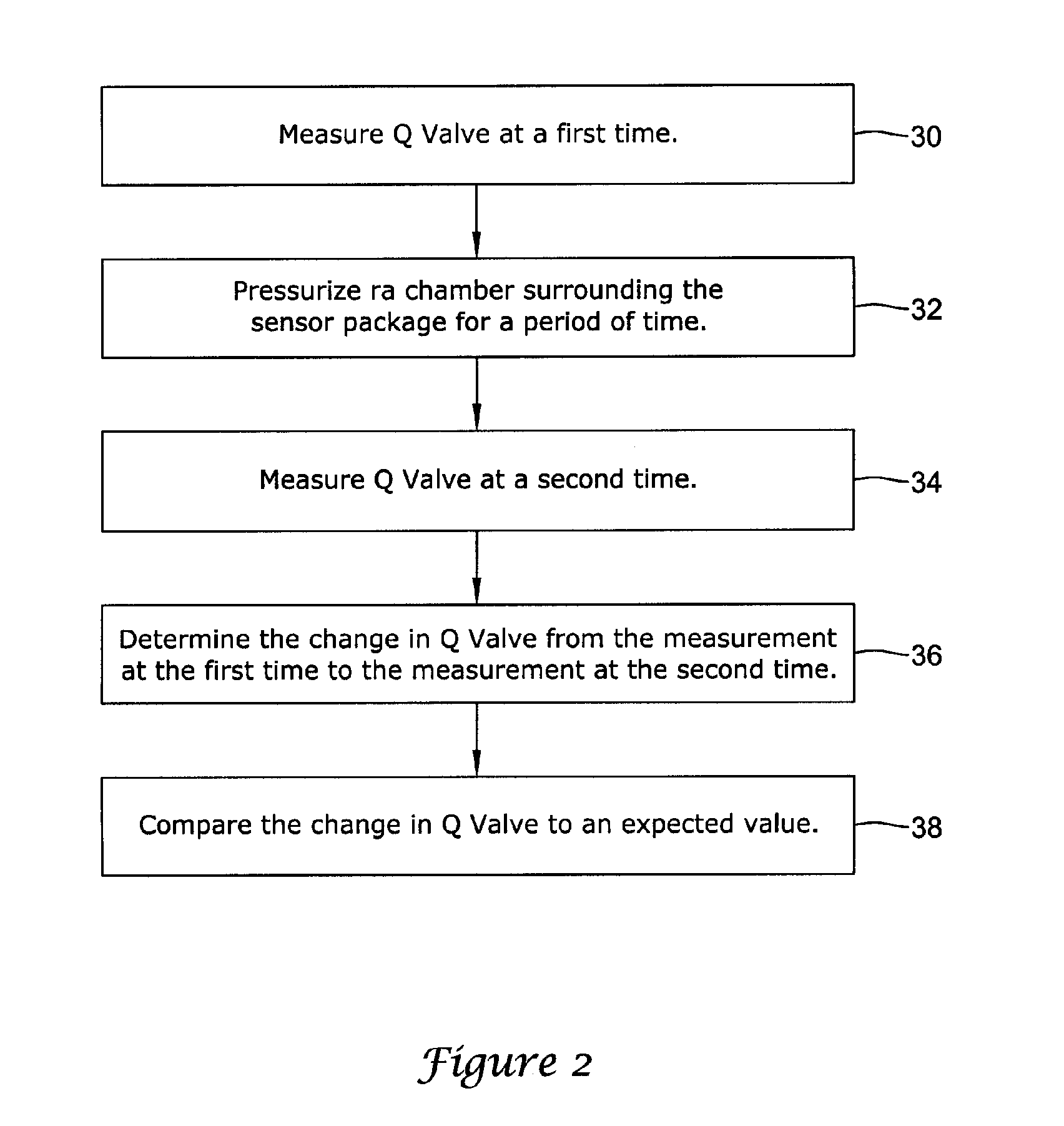

[0019] The following description should be read with reference to the drawings wherein like reference numerals indicate like elements throughout the several views. The detailed description and drawings show several embodiments, which are meant to be illustrative of the claimed invention.

[0020] In some applications, it is desirable to provide a MEMS sensor with an expected useful life in the range of 10 to 20 years, or greater. MEMS sensors for the automotive industry may be one such application. To have a relatively long life, a MEMS sensor package must typically maintain a pressure limit in a sensor cavity over the expected useful lifetime of the MEMS sensor. For example, and in one application, the pressure in the sensor cavity must be less than 47 mTorr over the expected lifetime of the MEMs sensor. Other applications may have higher or lower pressure limits for the MEMS sensor package, as desired. In one case, the MEMS sensor package may have a sensor cavity with a volume of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com