Assist Rod and Basket Assembly

a technology of baskets and rods, applied in the direction of transportation and packaging, railway signalling, roads, etc., can solve the problems of requiring unusually long ties to maintain the clearance necessary, and affecting the operation of the switch. , to achieve the effect of avoiding the need to worry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

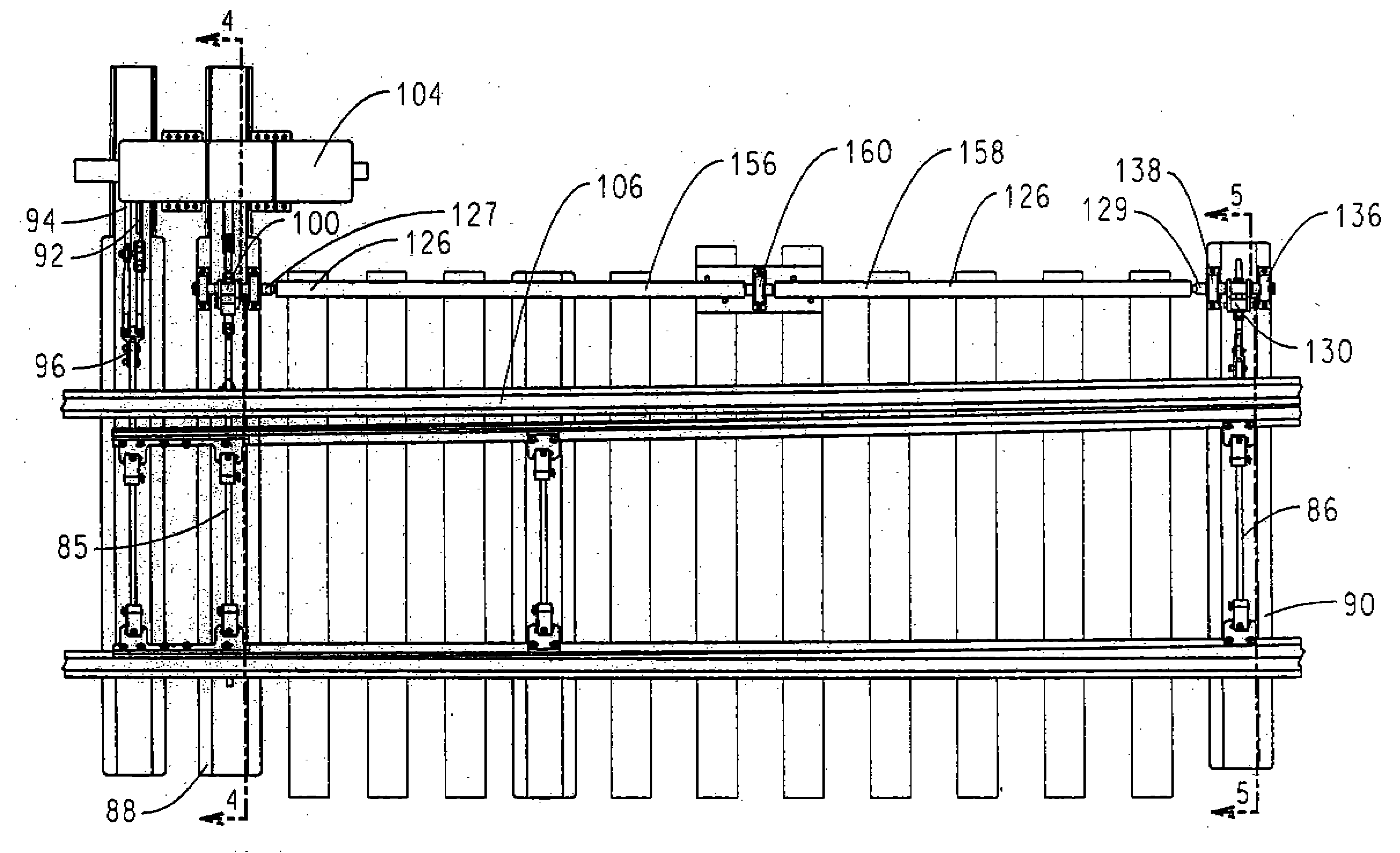

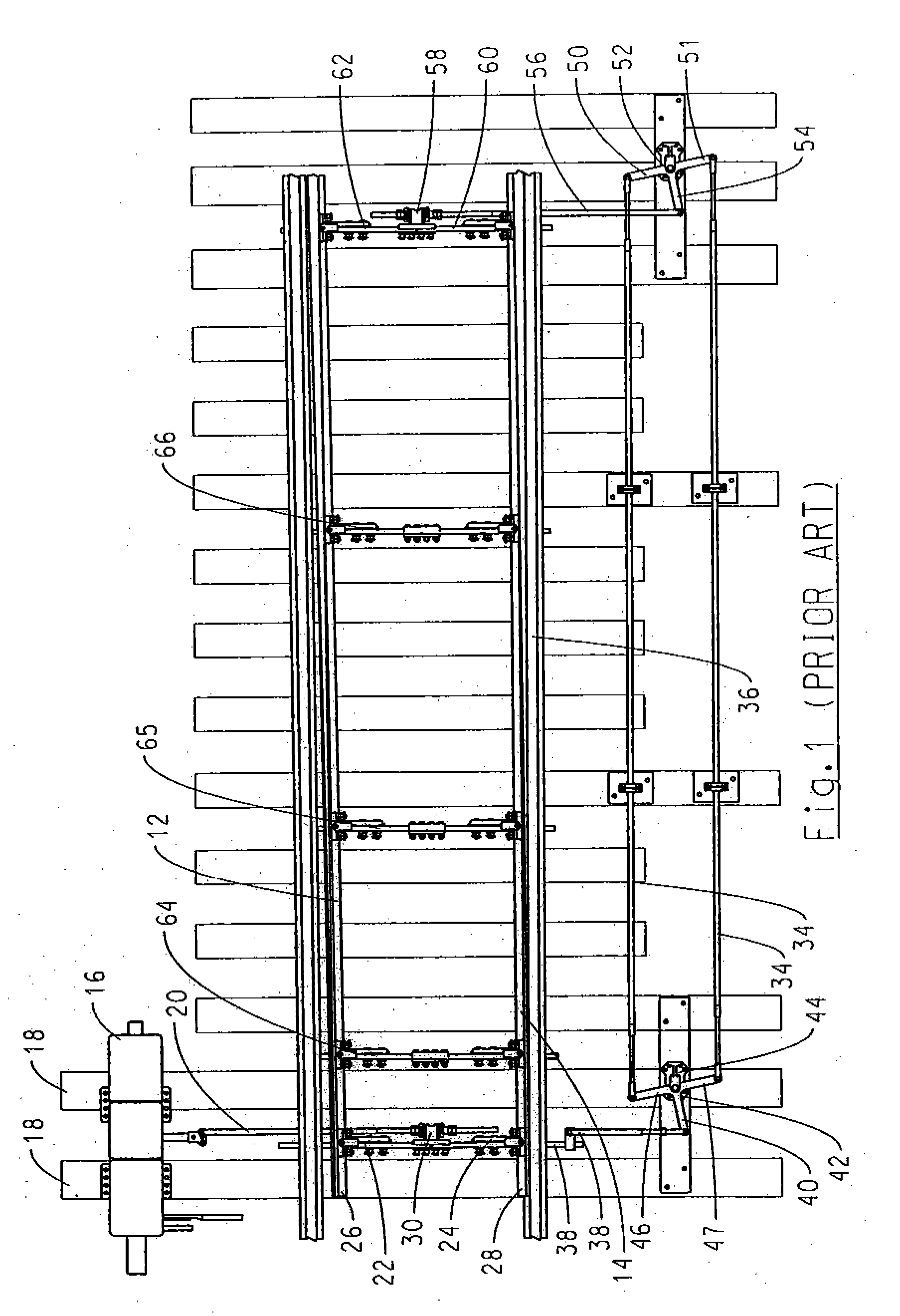

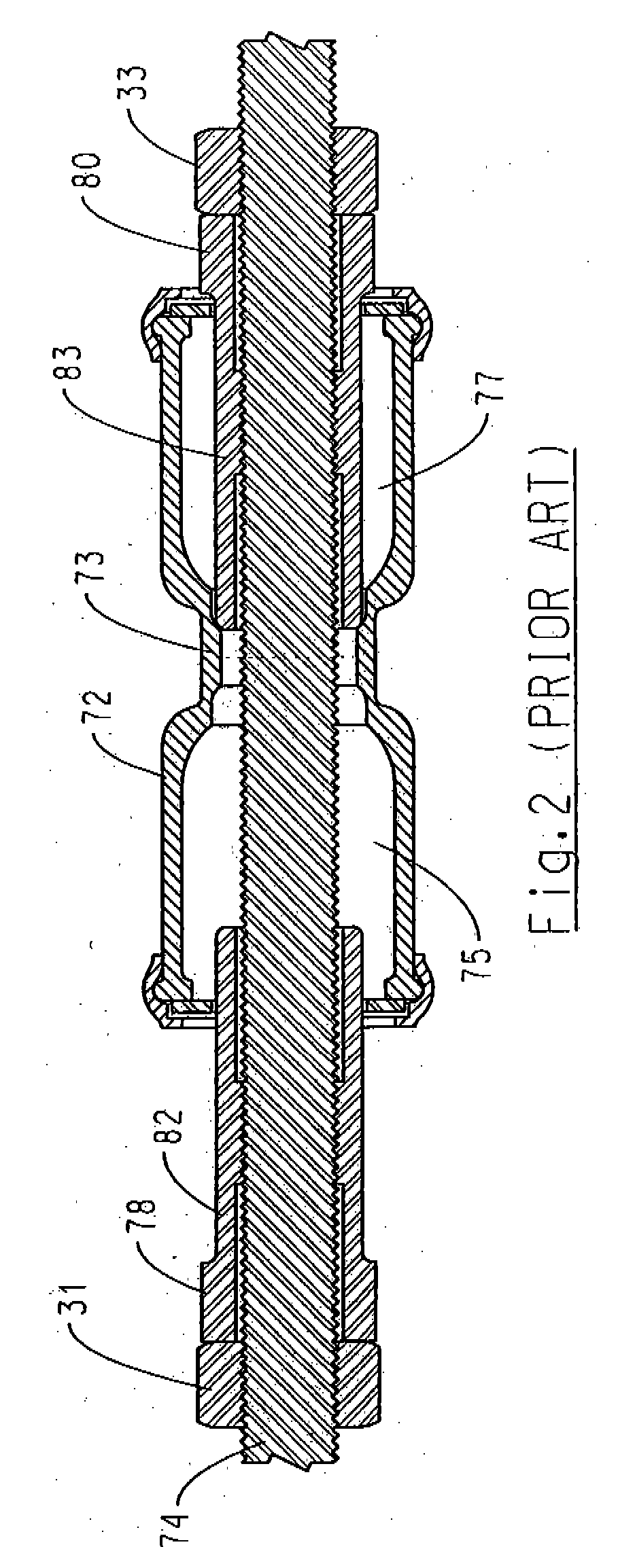

[0031]FIG. 1 illustrates a fairly typical prior art switch layout in which the assist rod and basket assembly is shown. The switch is used to throw the switch point (rails 12, 14).

[0032] A switch machine 16 is mounted on the outside of the rails on a switch stand plate attached to the ends of elongated ties 18. Switch machine 16 actuates a throw rod 20 that is connected to a pair of switch rods 22, 24 connected end to end and extending between the points 26, 28 of the switch point rails.

[0033] A front basket 30 is disposed between the throw rod 20 and the switch rods 22, 24. As is known, the basket 30 is adapted to slide a predetermined amount along the throw rod 20 before the basket will engage so as to actuate movement of the switch rods. As will be appreciated by reference to FIG. 2, the predetermined amount may be adjusted in the field by displacing basket nuts 31, 33 that are engaged on a threaded portion of the throw rod 20.

[0034] The switch may also include ancillary roddi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com