Nx steel lumber

a technology of c-shaped studs and elongated structures, applied in the direction of girders, joists, trusses, etc., can solve the problems of increased interest in fabricating and constructing buildings with frames, c-shaped studs that are susceptible to local buckling, bending, bending, bending, etc., to achieve the effect of increasing lateral resistance, increasing lateral resistance, and improving lateral resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

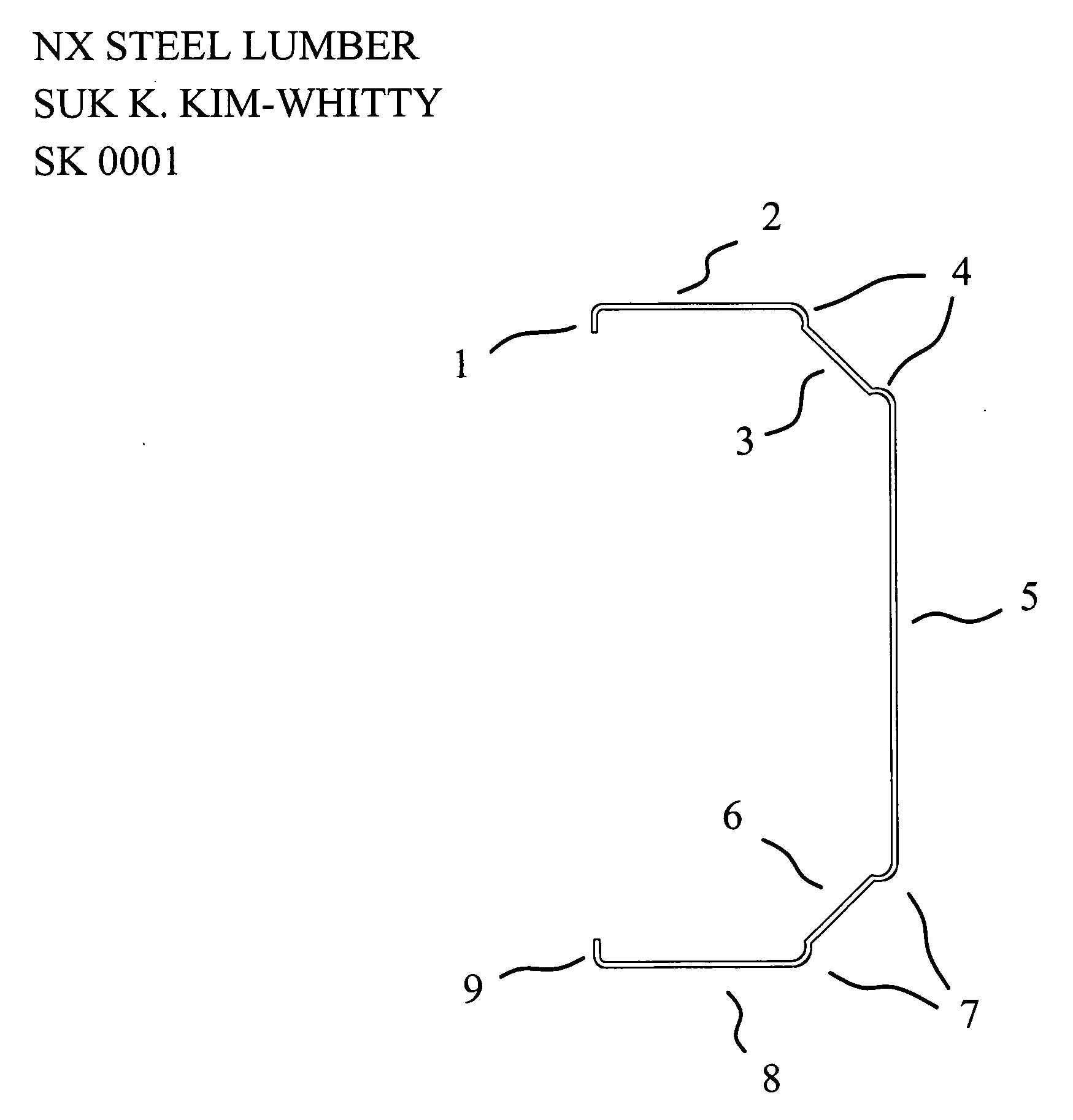

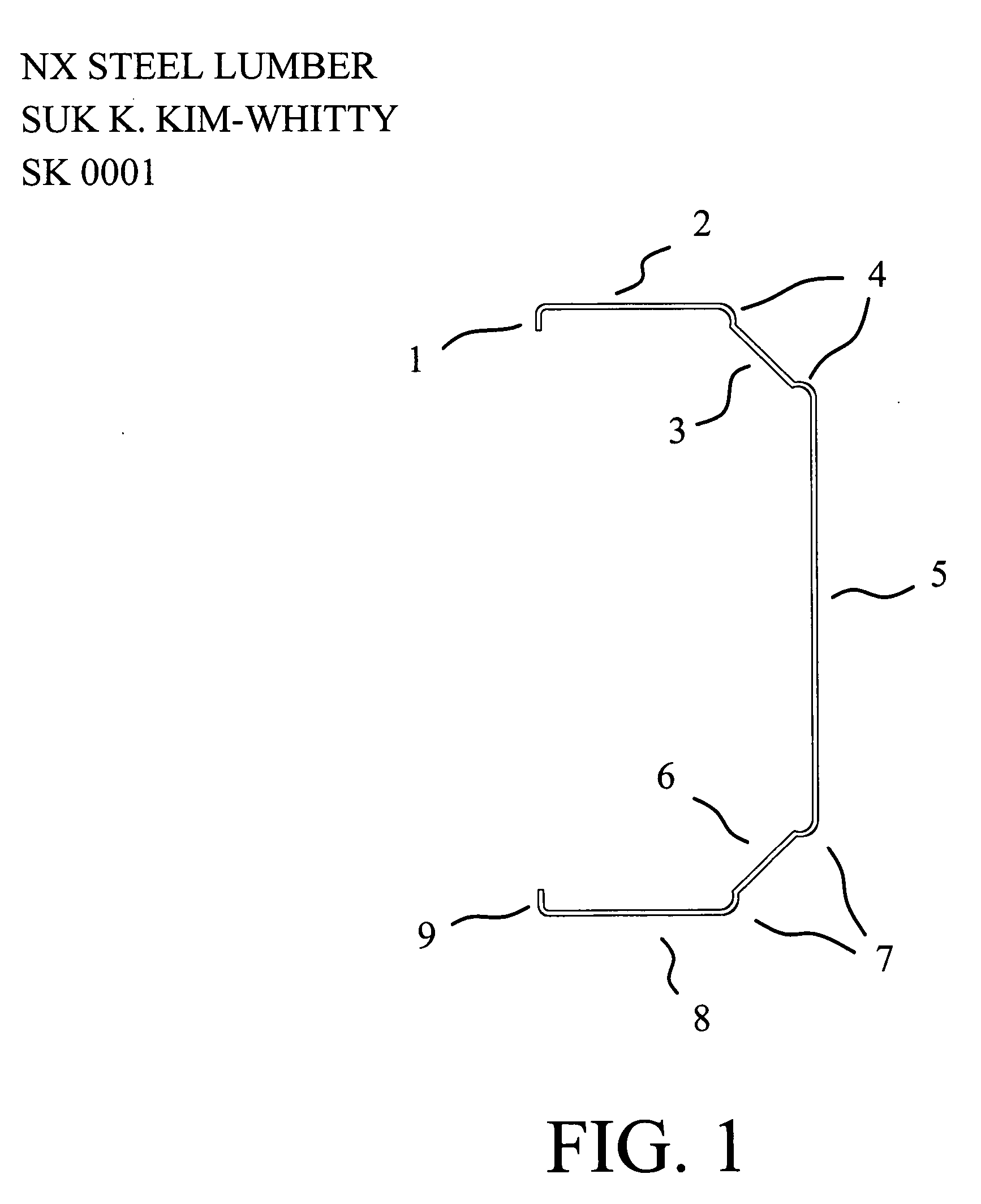

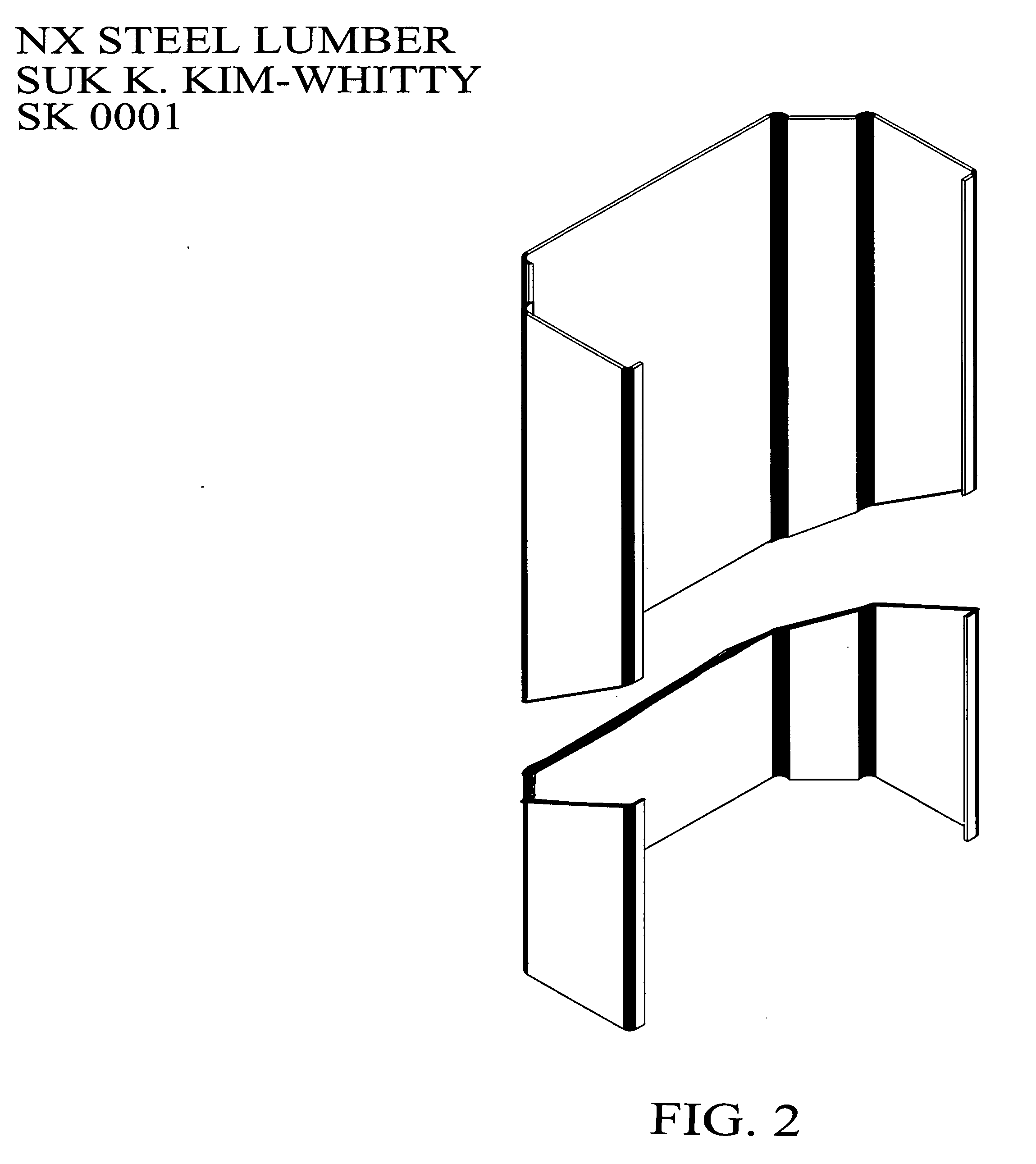

[0024] The structural member illustrated in FIG. 1 would be roll formed from thin, high tensile, galvanized steel in a structural grade. It can be roll formed by a single passage of an initially flat strip of sheet metal through a series of stands of forming rolls which successively modify the shape of the strip passing through the machines. FIG. 1 is a cross sectional view of a first embodiment of the C-shaped construction member. It comprises a longitudinal, elongate web member 5 having an angular intervening web extension 3 with variable exaggerated bends 4 and extending laterally to flange member 2 perpendicular to web member 5 and extending to an end wall member I of the flange member 2, in which the stiffening lip 1 is formed substantially parallel to web member 5 at the cross sectional end. The variable exaggerated bends 4, on both sides of flange member 3, satisfies safety requirements and provides improved lateral strength. The longitudinal, elongate web member 5, being the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com