Trash bin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

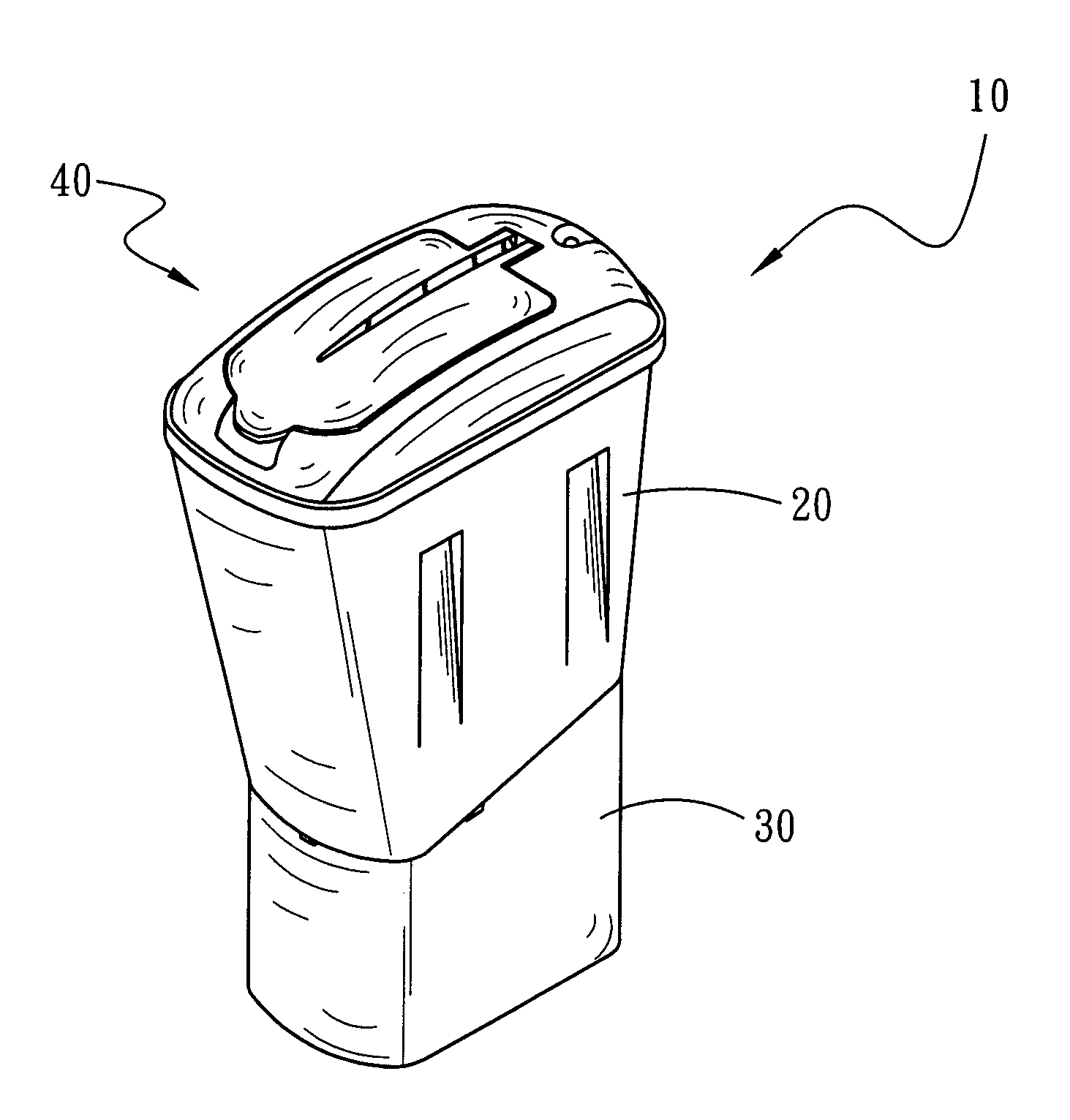

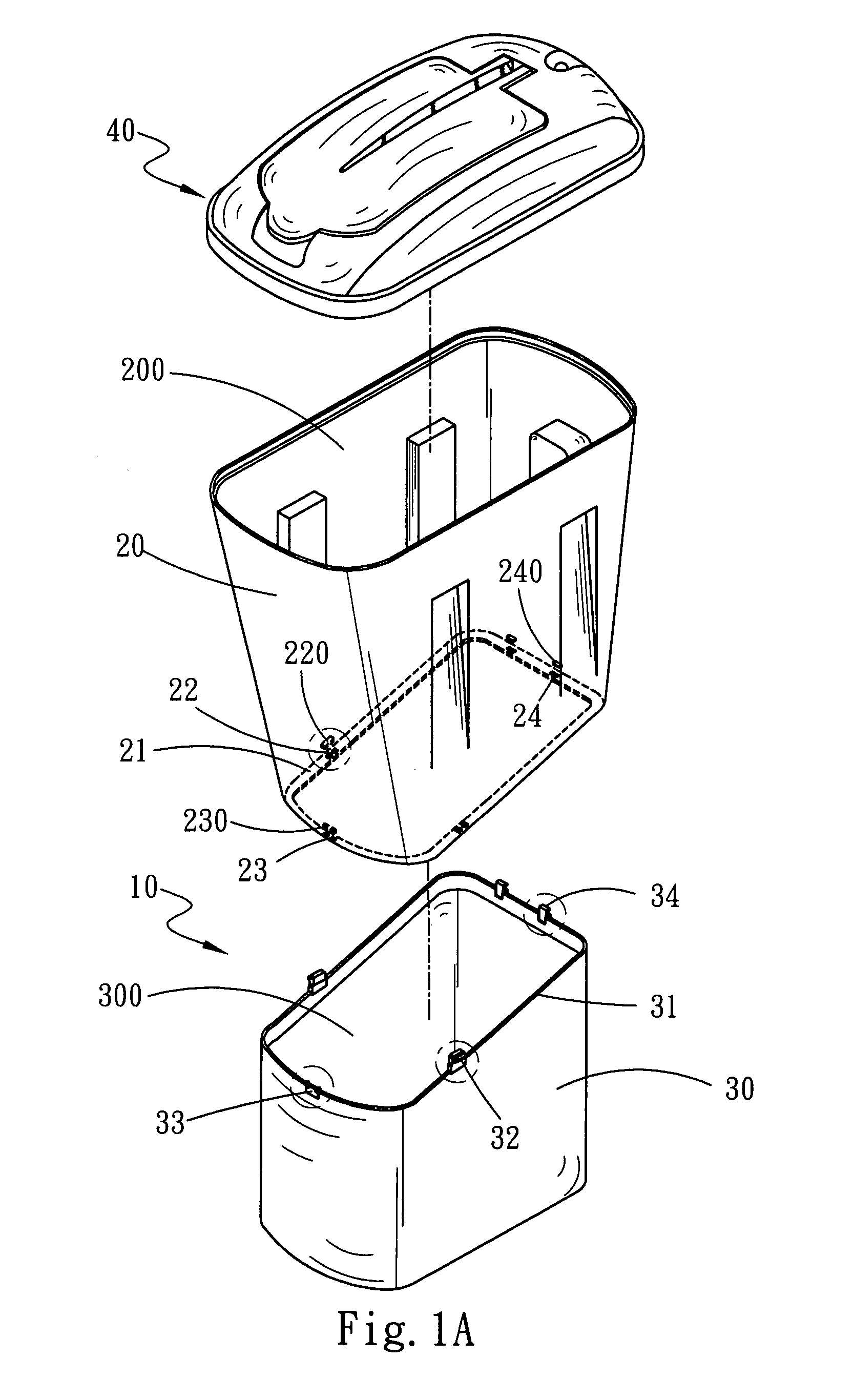

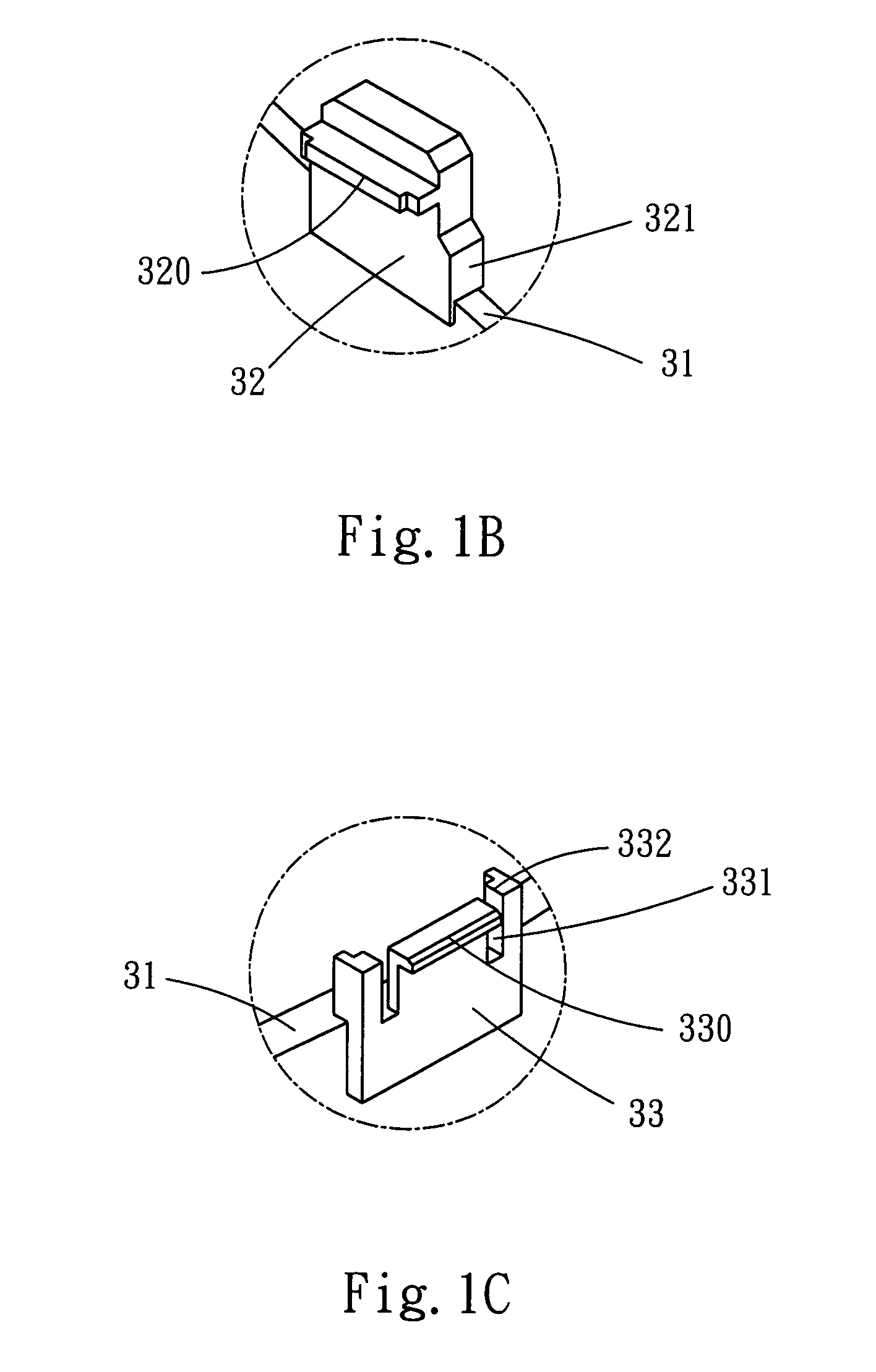

[0017] Please referring to FIGS. 1A through 1D, the trash bin according to the invention mainly includes a barrel body 10 and an upper lid 40 which can be lifted automatically. The barrel body 10 includes an upper barrel 20 and a lower barrel 30 that can be stacked and coupled together. In an embodiment shown in the drawings, the upper barrel 20 has a frame flange 21 on the bottom that has at least one or more apertures 22, 23 and 24. On a lateral side of each of the apertures 22, 23 and 24, there is a latch member 220, 230 and 240 (also referring to FIGS. 1A and 1E) extending upwards that may be coupled respectively with a corresponding coupling member 32, 33 and 34 located on two lateral sides and the front side and rear side of a upper coupling end 31 of the lower barrel 30. The upper barrel 20 has a first opening 200.

[0018] The lower barrel 30 has a second opening 300 on an upper side. The coupling members 32 on the two lateral sides of the coupling end 31 are opposing each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com