Diesel engine power estimation method

A diesel engine and power technology, applied in the direction of mechanical equipment, engine control, machine/engine, etc., can solve the problems of difficult installation of sensors, poor signal quality, etc., and achieve the effect of improving practicability, convenience, and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

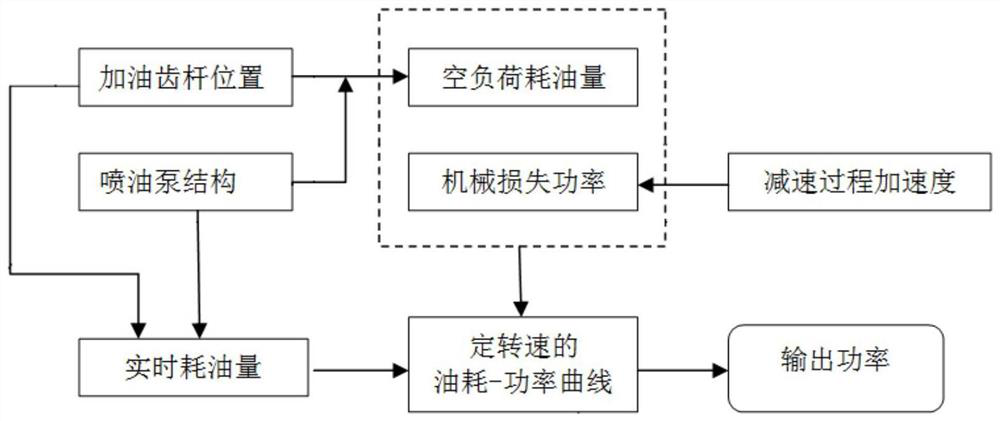

AI Technical Summary

Problems solved by technology

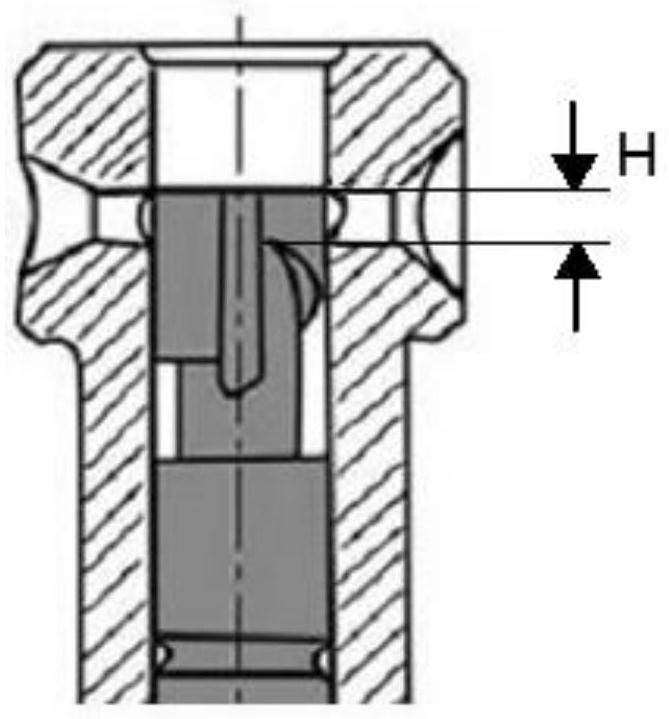

Method used

Image

Examples

Embodiment

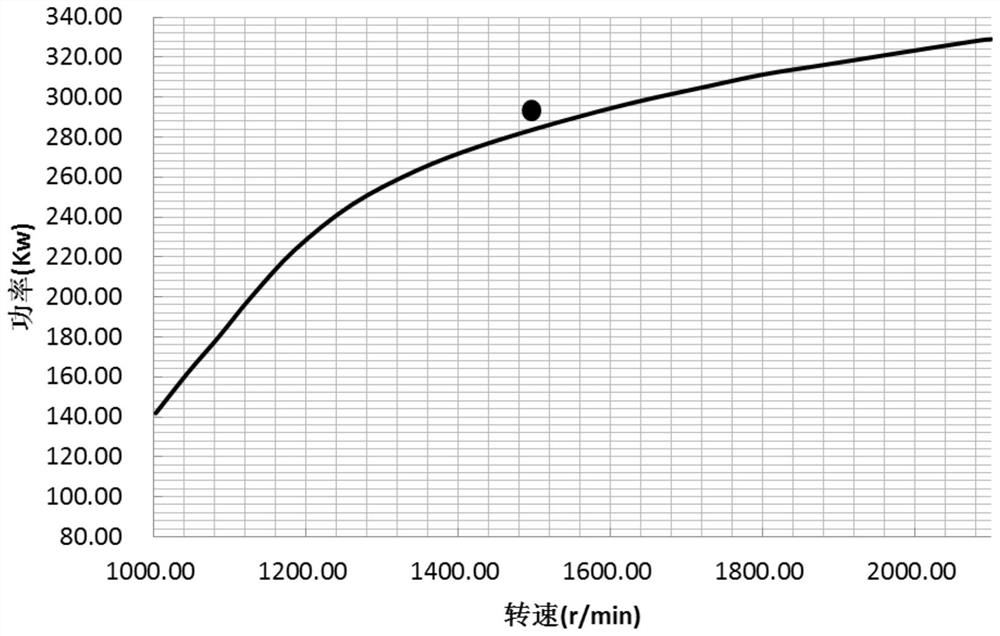

[0087] According to the estimation method, taking a certain type of diesel engine as an example, the plunger diameter of a certain type of diesel engine is 10mm, the plunger parameter is 2.74mm, the constant is 1.122, the ring gear diameter is 28.6mm, and the fixed speed is determined to be 1500r / min. The mechanical loss efficiency of the new diesel engine is 17.1KW. The displacement of the refueling gear rod is 3mm detected through the no-load operation of the diesel engine. The calculated no-load fuel consumption is 0.874g / s. The maximum refueling position of the diesel engine at 1500r / min. The displacement is 15mm, the calculated maximum fuel supply is 15.8g / s, and the calculated power value is 292.1KW. Compare the calculated power value with the external characteristic diagram such as image 3 As shown in the figure, the abscissa in the figure represents the speed of the diesel engine, and the ordinate represents the power of the diesel engine; the dots in the figure repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com