Receiving and launching barrel turnover device

A technology of sending and receiving bulbs and turning devices, which is applied in drilling equipment, wellbore/well components, earth-moving drilling and mining, etc., can solve the problems of large risks, inconvenient transportation, and inability to fix steadily, so as to reduce the impact and improve the practicability. and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

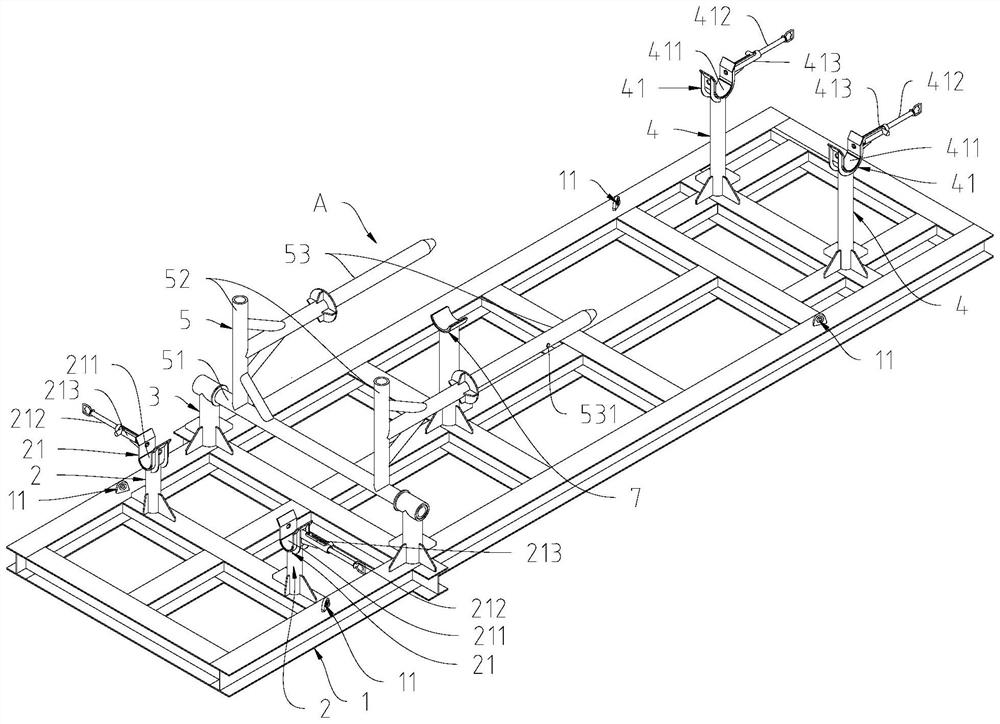

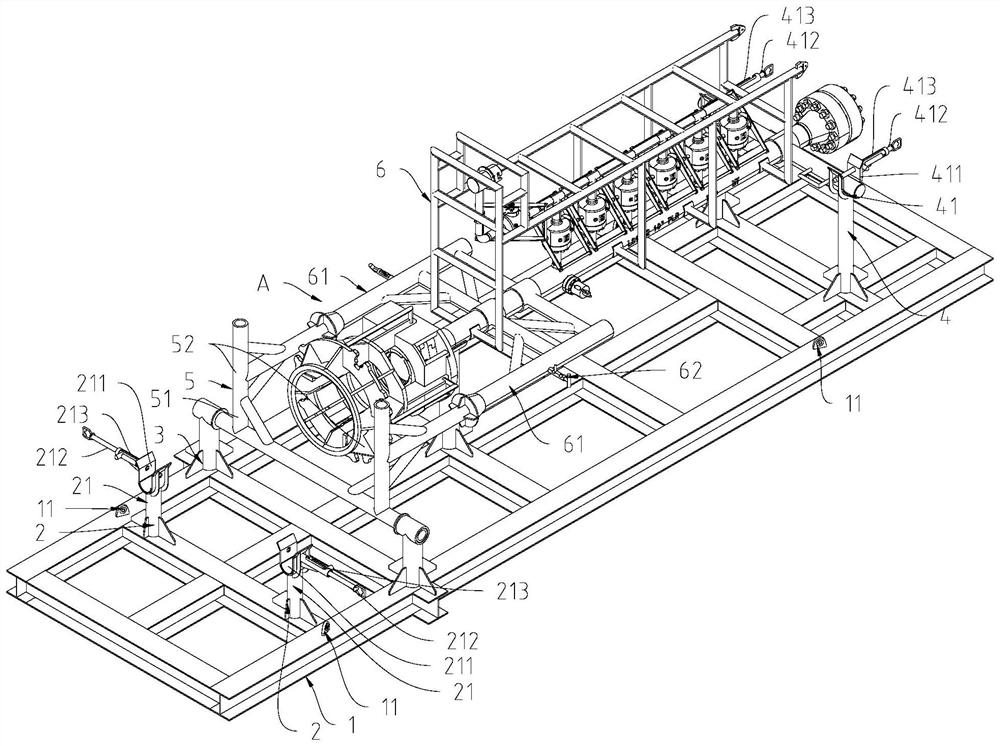

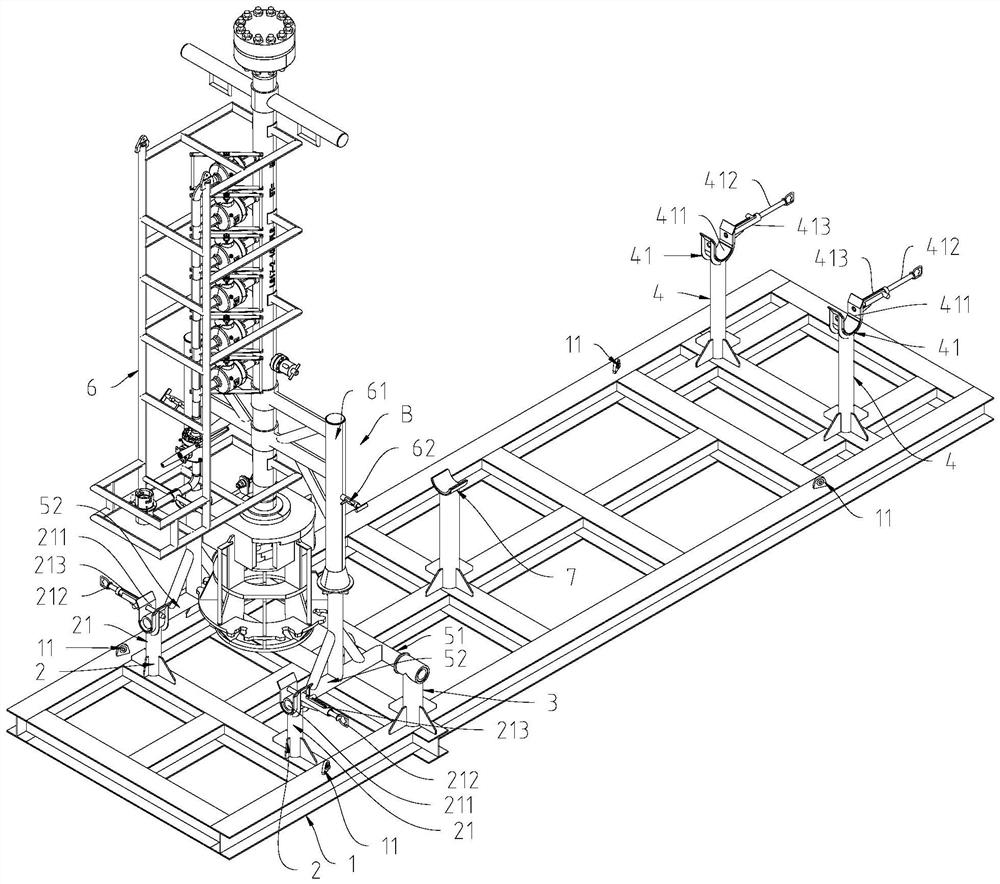

[0029] Such as Figure 1 to Figure 3 As shown, the receiving and receiving ball tube turning device in a preferred embodiment of the present invention includes a base 1 , a front support base 2 , a middle support base 3 , a rear support base 4 , and an overturn frame 5 .

[0030] The front support seat 2, the middle support seat 3, and the rear support seat 4 are arranged at intervals successively on the base 1, so that the receiving and receiving ball tube 6 can be supported when it is placed horizontally or erected.

[0031] The overturn frame 5 can rotate between the first rotation position A and the second rotation position B. The overturn frame 5 includes an overturn seat 51 that is rotatably engaged with the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com