Ultrasonic Blade Design for Scoring Double Angle Groove And Products Therefrom

a technology of ultrasonic blades and grooves, applied in the direction of manufacturing tools, pedestrian/occupant safety arrangements, vehicular safety arrangements, etc., can solve the problems of affecting the work environment, affecting the quality of work, so as to prevent the front side of the skin from being readout at a reasonable high rate of speed, the effect of preventing the side of the groove from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

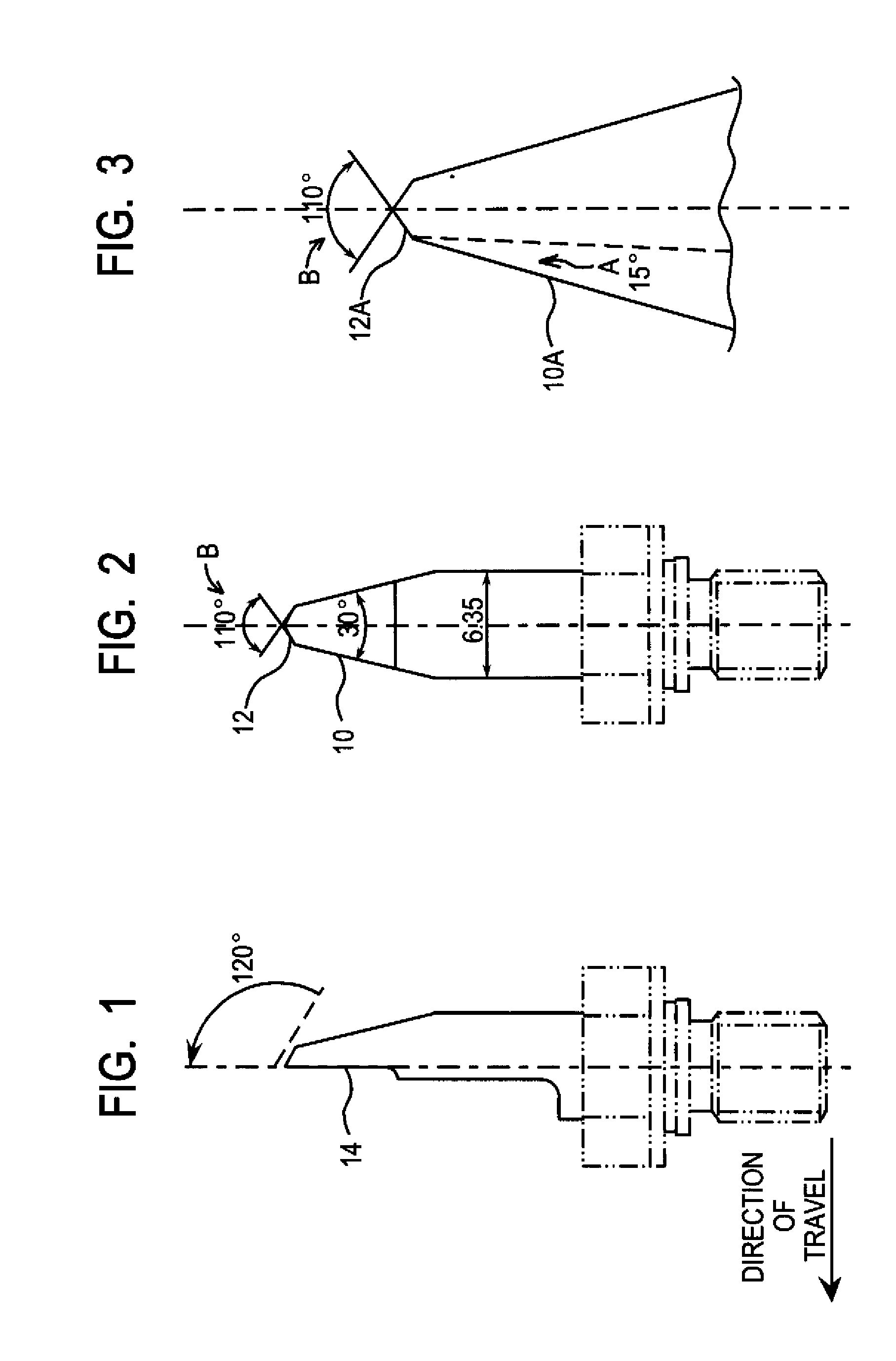

[0023]FIG. 1 illustrates a side view of the preferred ultrasonic blade that can be used in accordance with the present invention. However, it should be appreciated that in broad context, any blade that operates to provide the V-shaped groove described herein is contemplated.

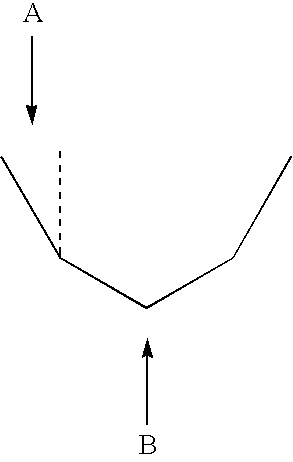

[0024] With attention directed to FIG. 2, as illustrated therein the blade contains a double angle V-shaped configuration. Shown at 10 is the first angle cutting surface A which angle is less than the angle of cutting surface B which is shown generally at 12. In the context of the present invention, angle A is preferably between 5-30 degrees and angle B is between 75-150 degrees. In addition it should be understood that the present invention contemplates all values therebetween in one (1) degree increments. More preferred ranges therefore include angle A of 10-20 degrees and angle B of 90-130 degrees. In a most preferred embodiment, angle A is about 15 degrees and angle B is about 110 degrees. Attention is direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com