Rechargeable vacuum cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

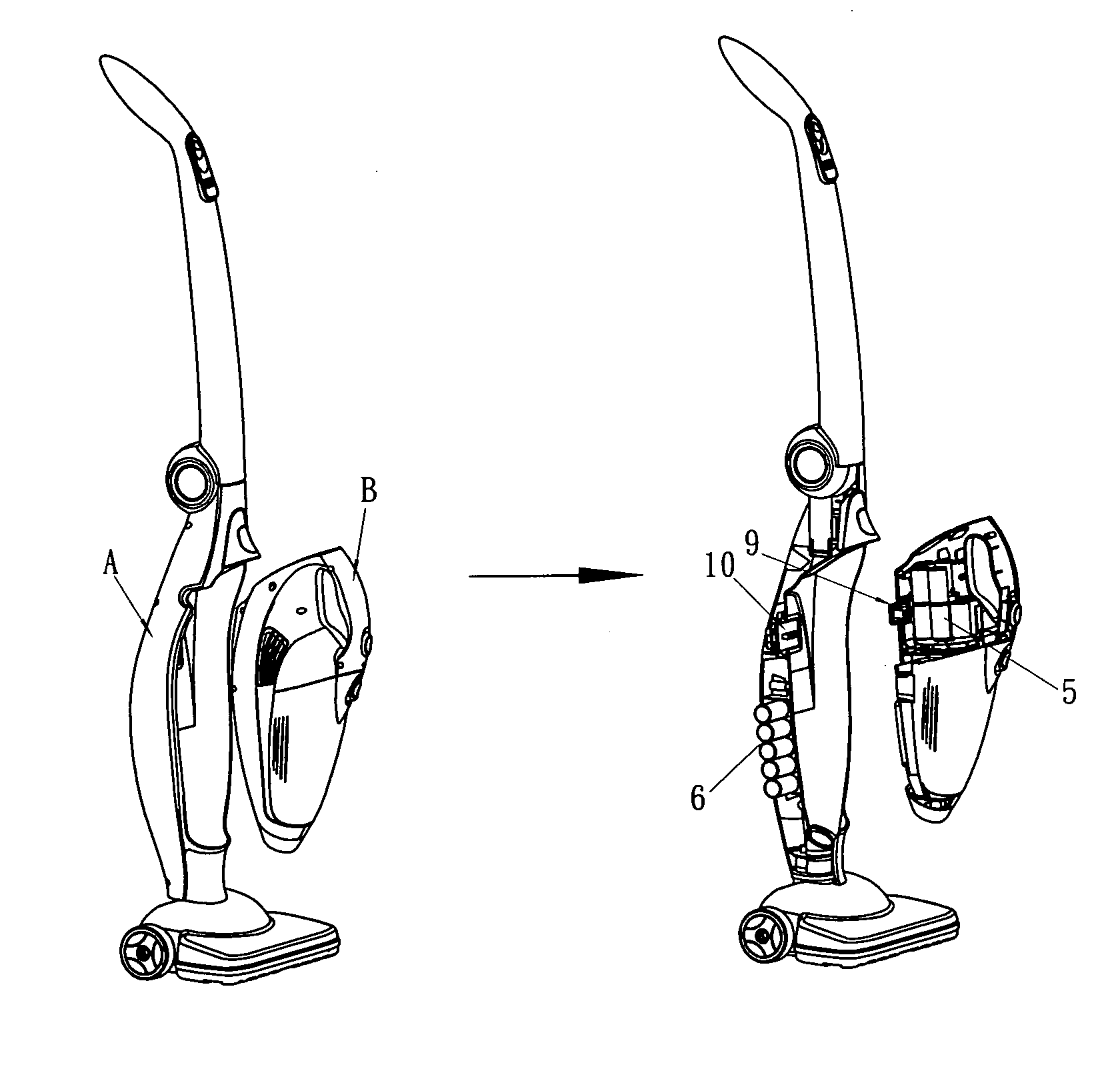

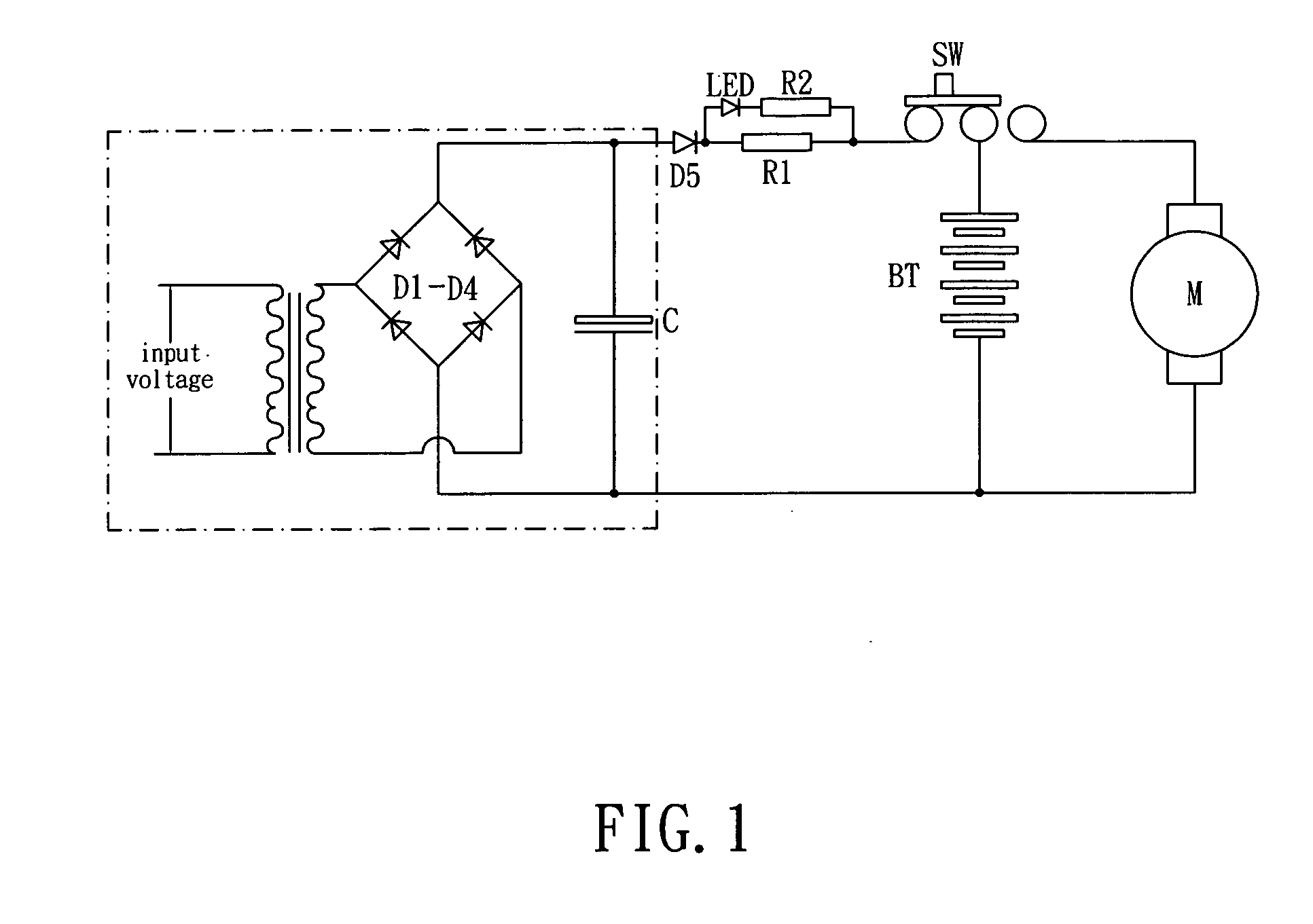

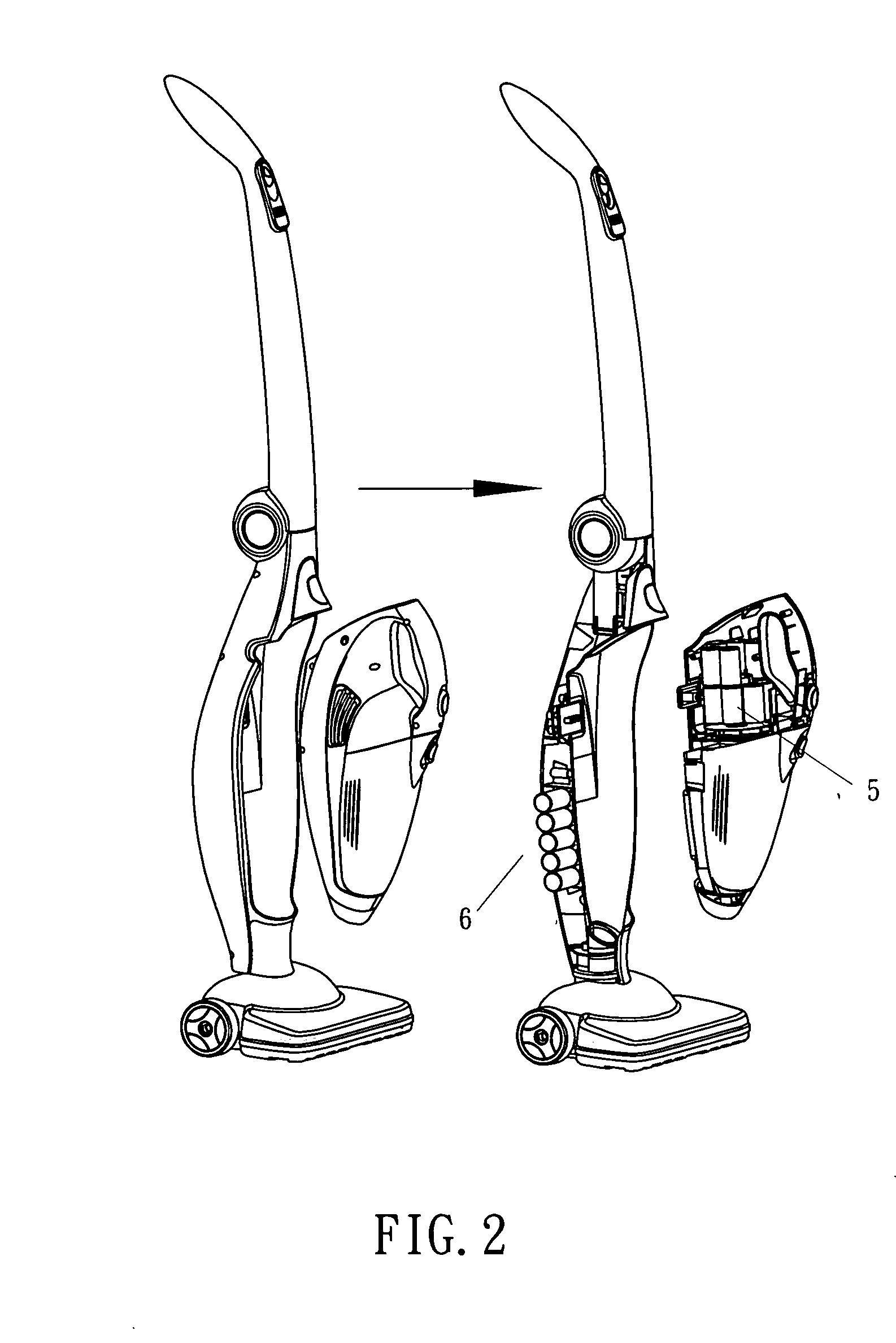

[0025] The various objects and advantages of the present invention will be more readily understood from the following detailed description when read in conjunction with the appended drawings.

[0026] The objective of the present invention is using the technique of voltage dividing to rechargeable vacuum cleaners equipped with more than one sets of rechargeable batteries, whereby the input voltage of the motor is kept constant when: (1) one of the sets of rechargeable batteries is used alone; (2) two sets of rechargeable batteries are used together; and (3) there is an imbalance in electricity capacity over the sets of rechargeable batteries.

[0027] Referring to FIG. 4, the positive-polarity terminals of two sets of rechargeable batteries BT1, BT2 are connected to a terminal of a motor through a power-supply control unit, selected from a silicon assembly and a diode. The negative-polarity terminals of the sets of rechargeable batteries BT1, BT2 are connected to the other terminal of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com