Apparatus and method for assembling vehicle wheel

a technology for vehicles and components, applied in the field of wheels of vehicles, can solve the problems of air of tires leaking through the broken portion of the valve stem, rubber of valve stems may be broken, and air of tires may leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] With reference to the accompanying drawings, exemplary embodiments of the present invention will be described. As those skilled in the art will realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention.

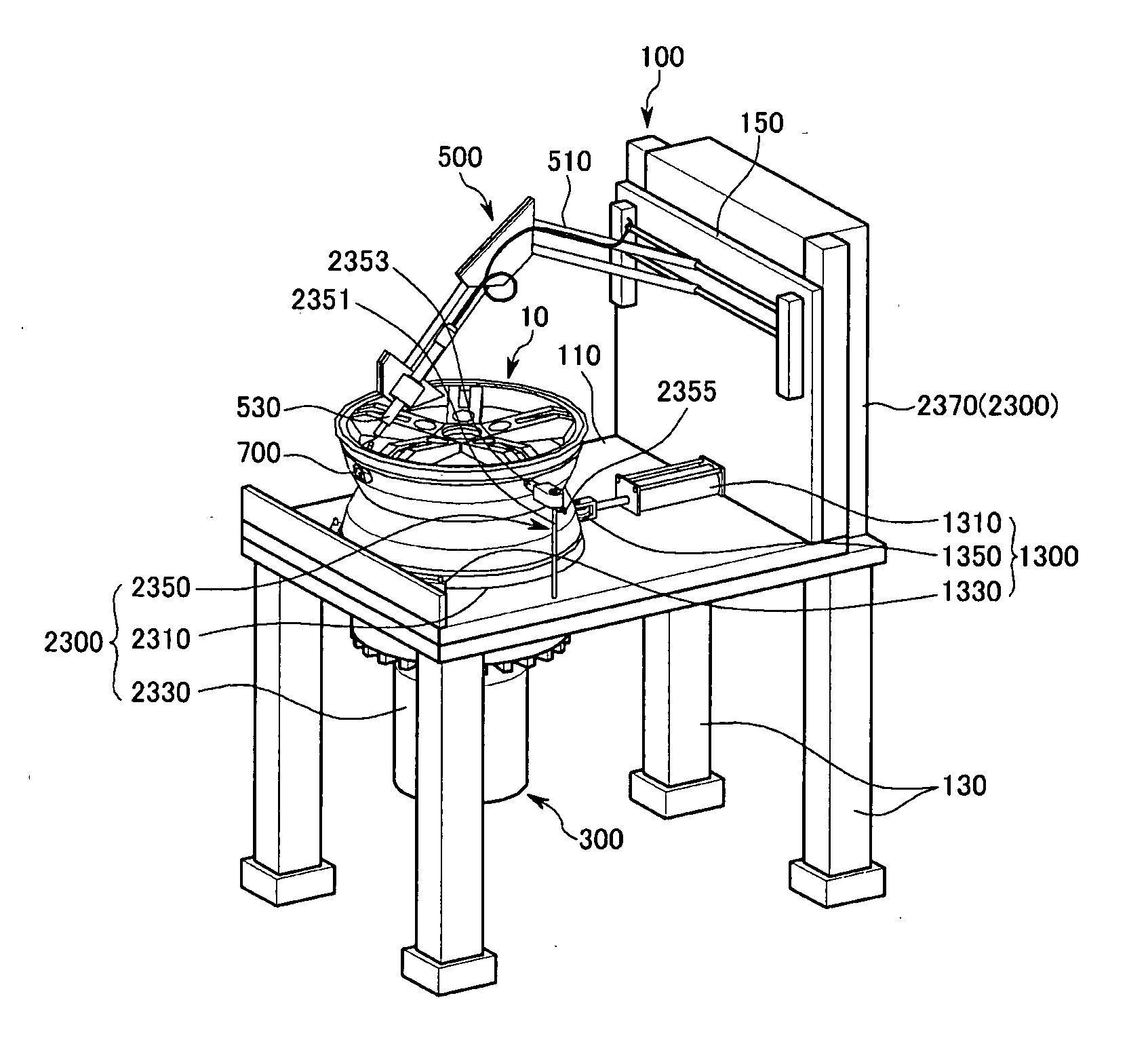

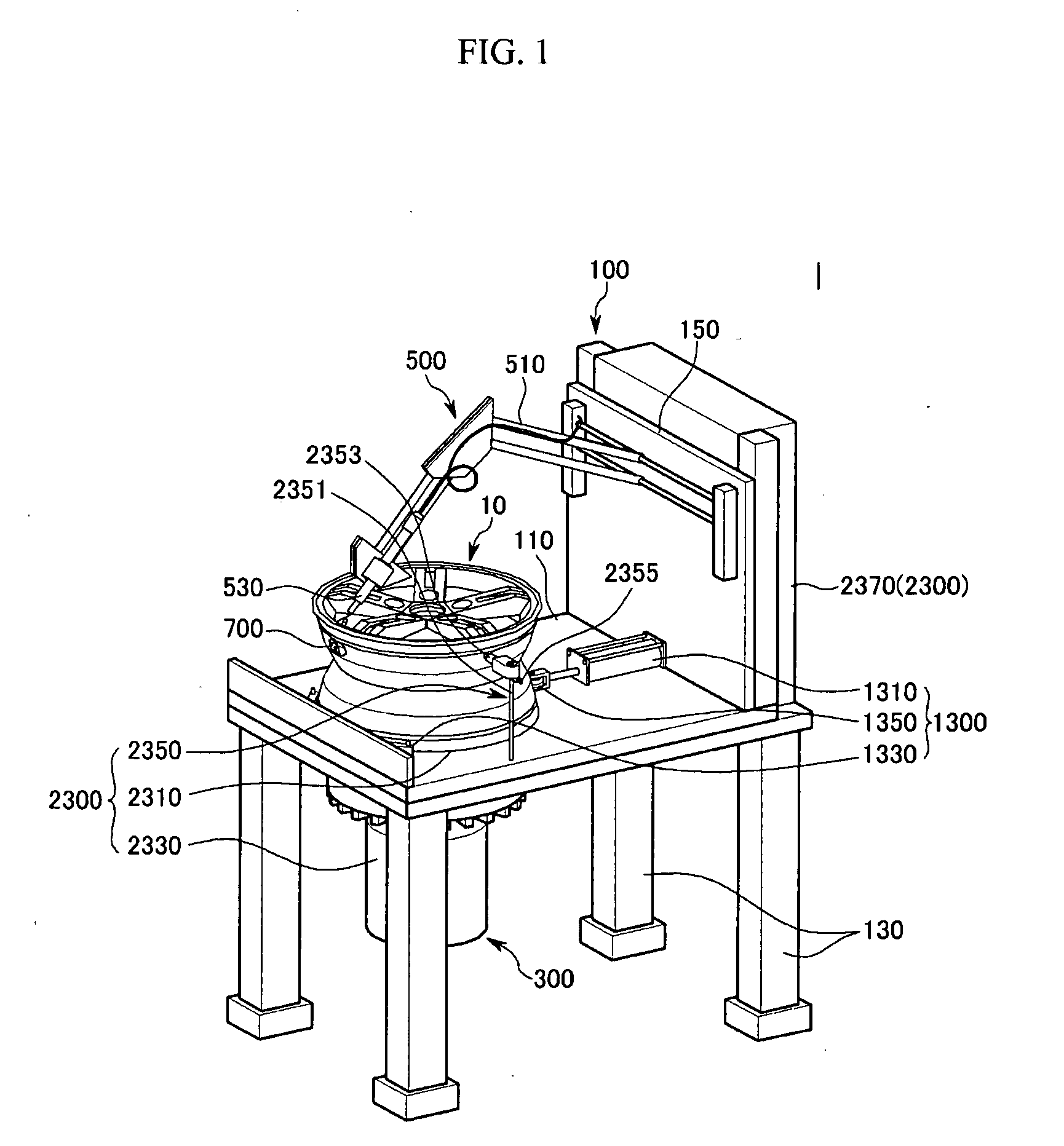

[0031] An apparatus for assembling a vehicle wheel according to an exemplary embodiment of the present invention, as shown in FIGS. 1 and 2, includes a workbench 100, an aligner 300, and a coupling unit 500.

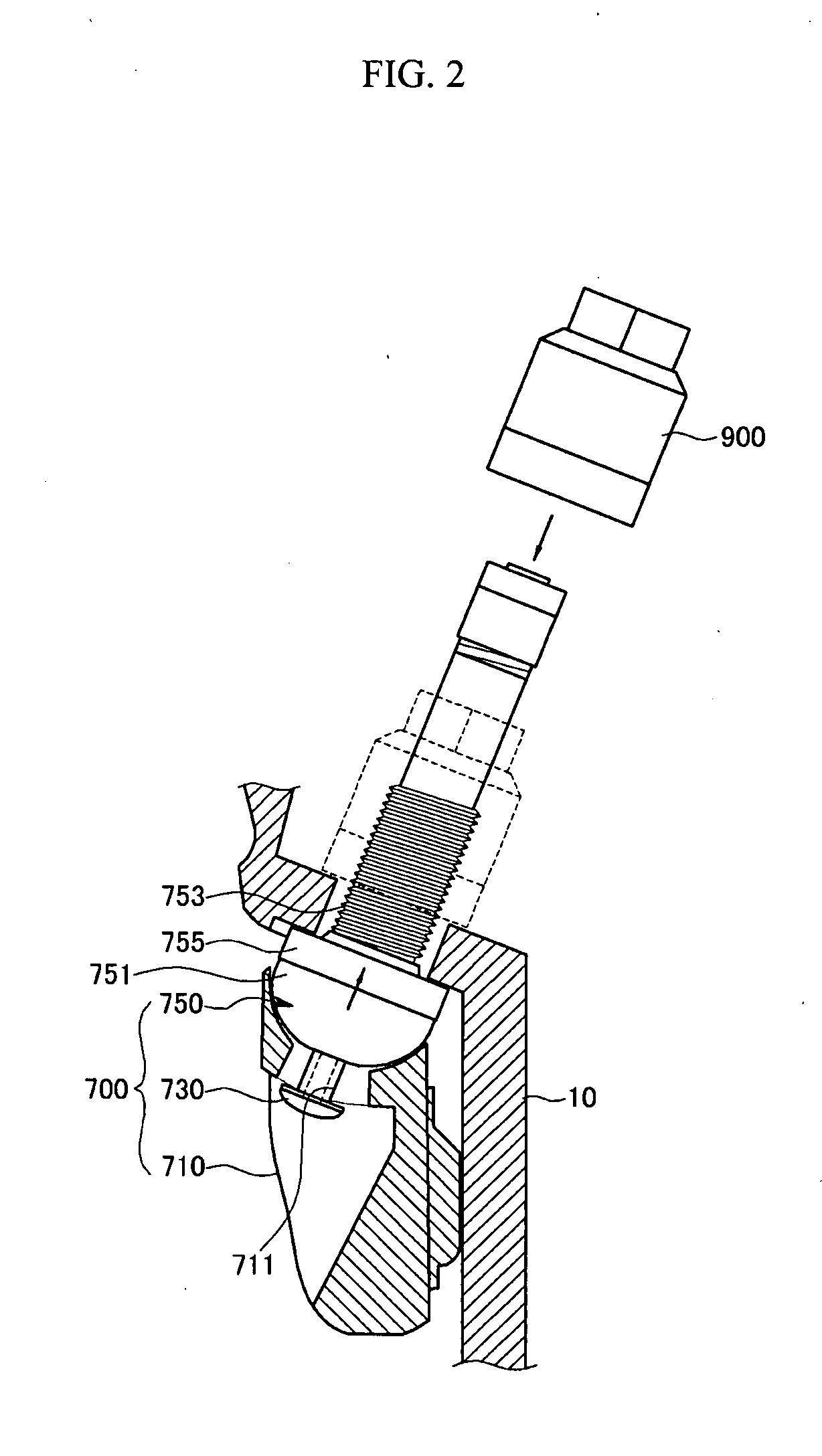

[0032] The workbench 100 accommodates a,wheel 10 to which a first detector 700 is coupled by a coupling member 900 at a first predetermined torque. The aligner 300 is disposed on the workbench 100 and aligns a position of the coupling member 900. The coupling unit 500 is disposed on the workbench 100 and provides torque to the coupling member 900 until the torque reaches a second predetermined torque with a gradual increase.

[0033] First, with reference to FIG. 1, the workbench 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com