Porous carbon electrode substrate and its production method and carbon fiber paper

a carbon electrode and substrate technology, applied in the direction of cell components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of poor conductivity, many electrodes ever made available are thick and easy to break, and the thickness of the substrate is too thick, so as to achieve high conductivity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0065] Fiber bundles of polyacrylonitrile (PAN) type carbon fibers with an average fiber diameter of 4 μm were cut to obtain short fibers with an average fiber length of 3 mm.

[0066] Next, the short fiber bundles were spread in water and sufficiently dispersed, then short fibers of polyvinyl alcohol (PVA) (VBP 105-1 in cut length 3 mm; produced by Kuraray Co., Ltd.) as a binder was evenly dispersed in 15% by mass in the total amount of the carbon fibers and PVA, paper manufacturing was manually carried out according to JIS P-8209 method using a standard square sheet machine (No.2555 Standard square sheet machine; produced by Kumagai Riki Industry Co., Ltd.), and the obtained paper was dried to obtain carbon fiber paper. PVA fibers were in half-dissolved state and contacted the carbon fibers with one another. The areal weight of the obtained carbon fiber paper was 60 g / cm2.

[0067] The carbon fiber paper was immersed in an ethanol solution containing 15% by mass of a phenol resin (Res...

example 2

[0070] An electrode substrate was obtained in the same manner as the example 1 except that the paper manufacturing was continuously carried out in the following manner.

[0071] Fiber bundles of short carbon fibers were spread in water in a slurry tank and sufficiently dispersed, and then short fibers of polyvinyl alcohol (PVA) as a binder (the same one used in the example 1) was evenly dispersed and web was sent out. The sent out web was passed through short net plate and dried by a drier to obtain carbon fiber paper with the length of 20 m. The obtained carbon fiber paper had the areal weight of 60 g / cm2. Further the long carbon fiber paper was cut into 25 cm length for the successive processes.

[0072] The electrode substrate of the present invention was provided with remarkably improved strength owing to the continuous paper-manufacturing and was also excellent in the deflection.

example 3

[0073] A long carbon fiber paper sheet was produced in the same manner as the example 2, and the carbon fiber paper was impregnated with a thermosetting resin by a dip-nip method. That is, the carbon fiber paper was continuously sent to a tray containing a methanol solution containing of 20% by weight of a phenol resin (Phenolite J-325, produced by Dainippon Ink and Chemicals, Inc.), the resin was squeezed by a squeezing apparatus, and then a hot air was continuously blown to dry and obtain resin-impregnated carbon fiber paper. In this case 100 parts by mass of carbon fibers were impregnated with 100 parts by mass of the phenol resin.

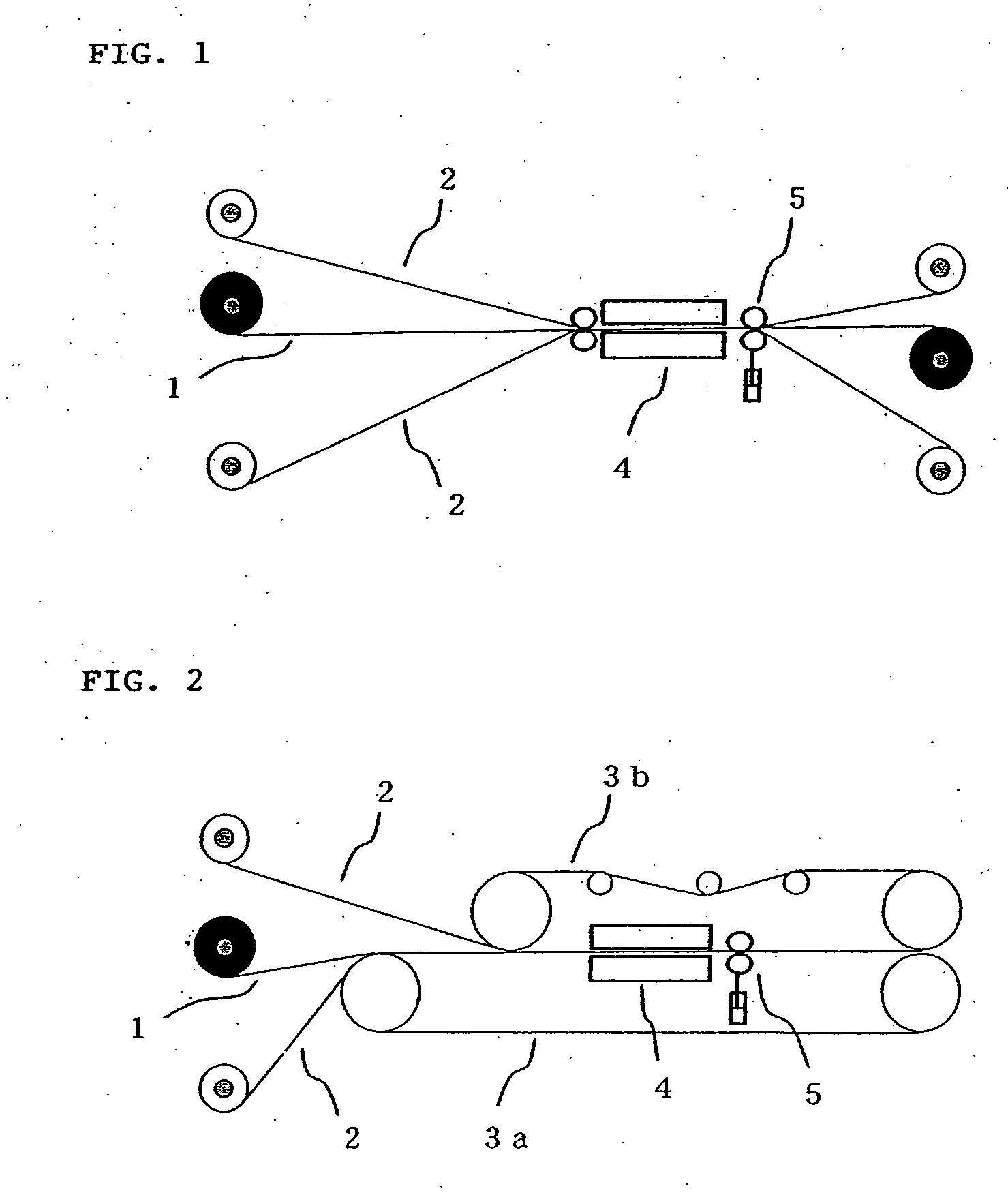

[0074] Next, the resin-impregnated carbon fiber paper was continuously heated and pressed by a continuous type hot roll press machine illustrated in FIG. 1 to obtain resin-cured carbon fiber paper. That is, the above described resin-impregnated carbon fiber paper 1 was sent out the rolls and while being sandwiched between mold release agent-coated subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com