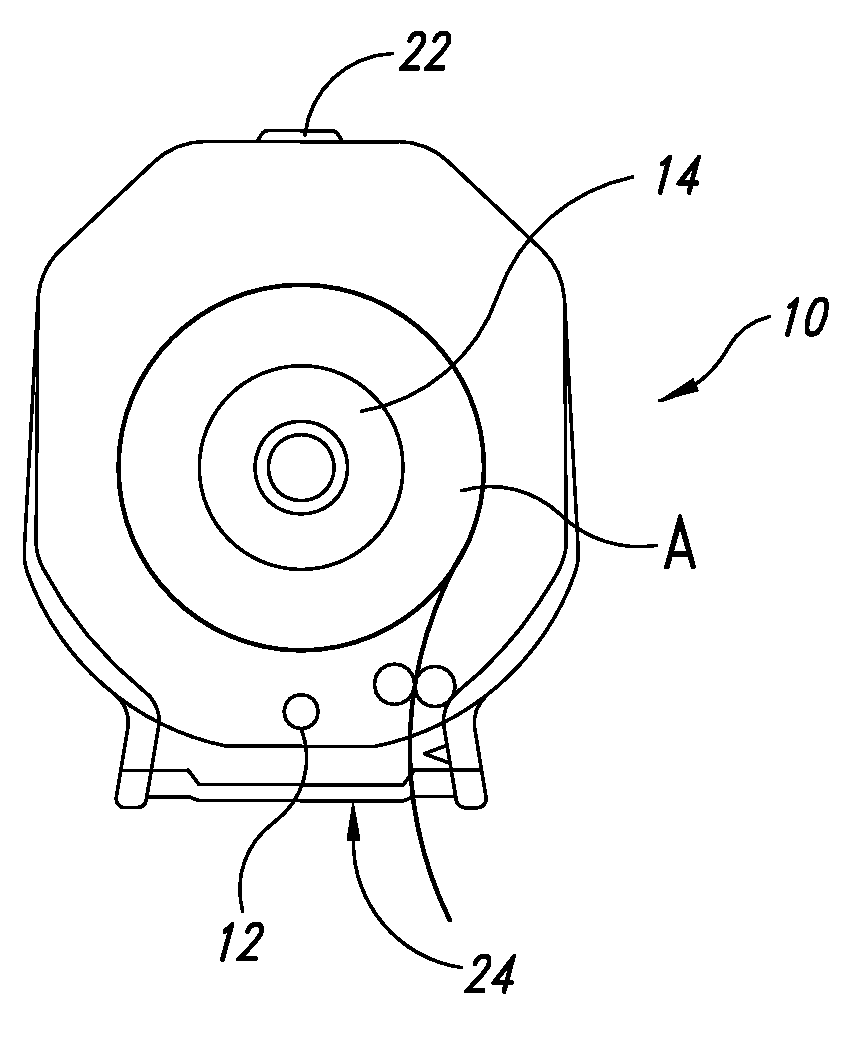

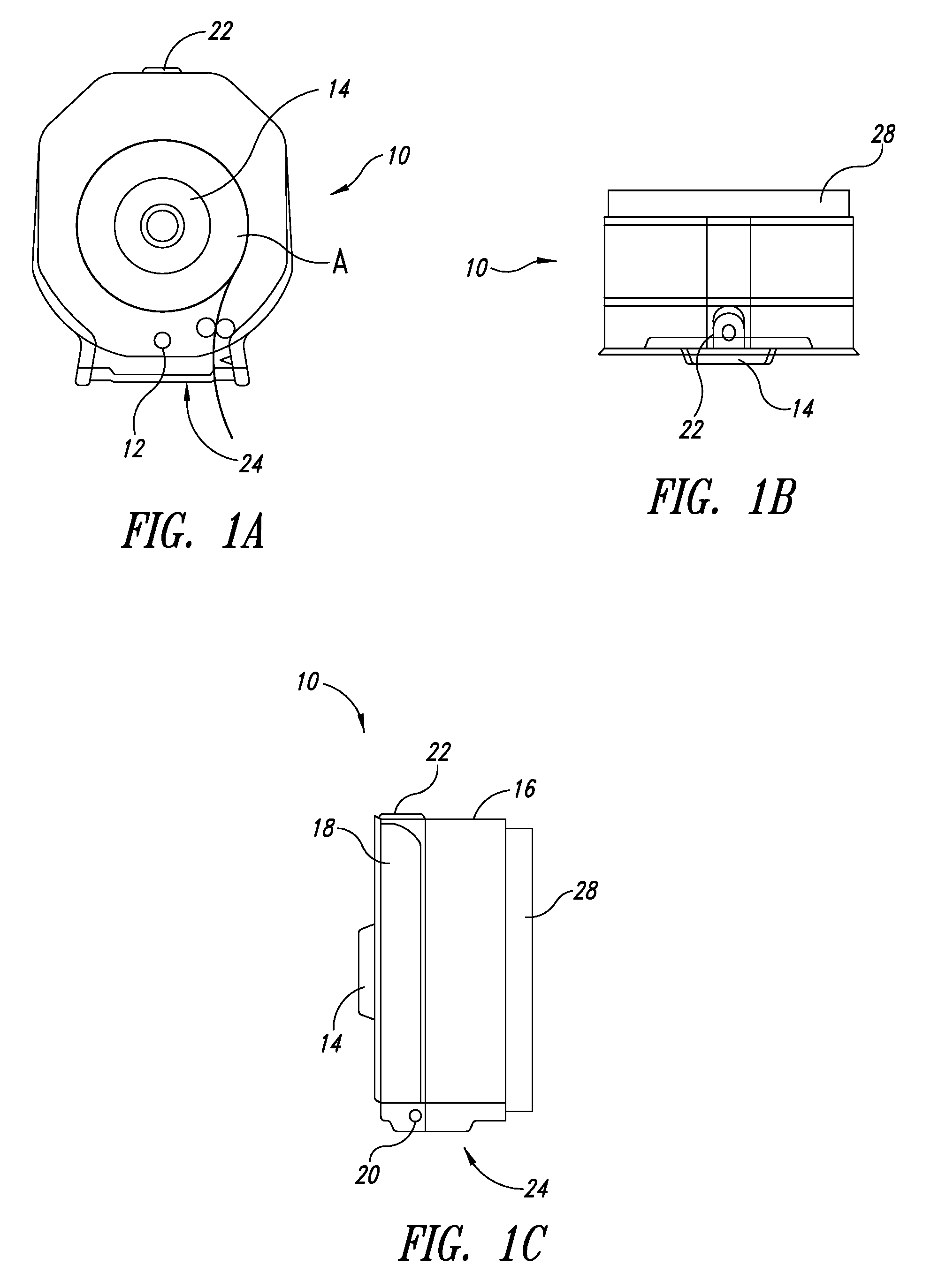

Automated toilet paper dispenser

a dispenser and automatic technology, applied in the field of paper dispensers, can solve the problems of toilet paper waste, theft, and unwinding the entire roll, and achieve the effects of reducing the number of rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0041] Referring to FIGS. 4(a)-(d) and 5 and according to the invention, the automated dispensing assembly of the dispenser 10 is modified so that the rollers 30, 34 are replaced by a drive roller 100 which is in direct contact with the surface of the paper roll A. The drive roller 100 has an axle 102 that is movably mounted to the housing 16 and is biased against the paper roll A such that the drive roller 100 is always in contact with the roll A regardless of the roll's size. The axle 102 extends through a track 104 in the housing 16 and is weighted at one end so that gravity biases the drive roller 100 downwards through the track 104 and against the roll A. Alternatively, the drive roller 100 can be biased using springs or other biasing means known in the art.

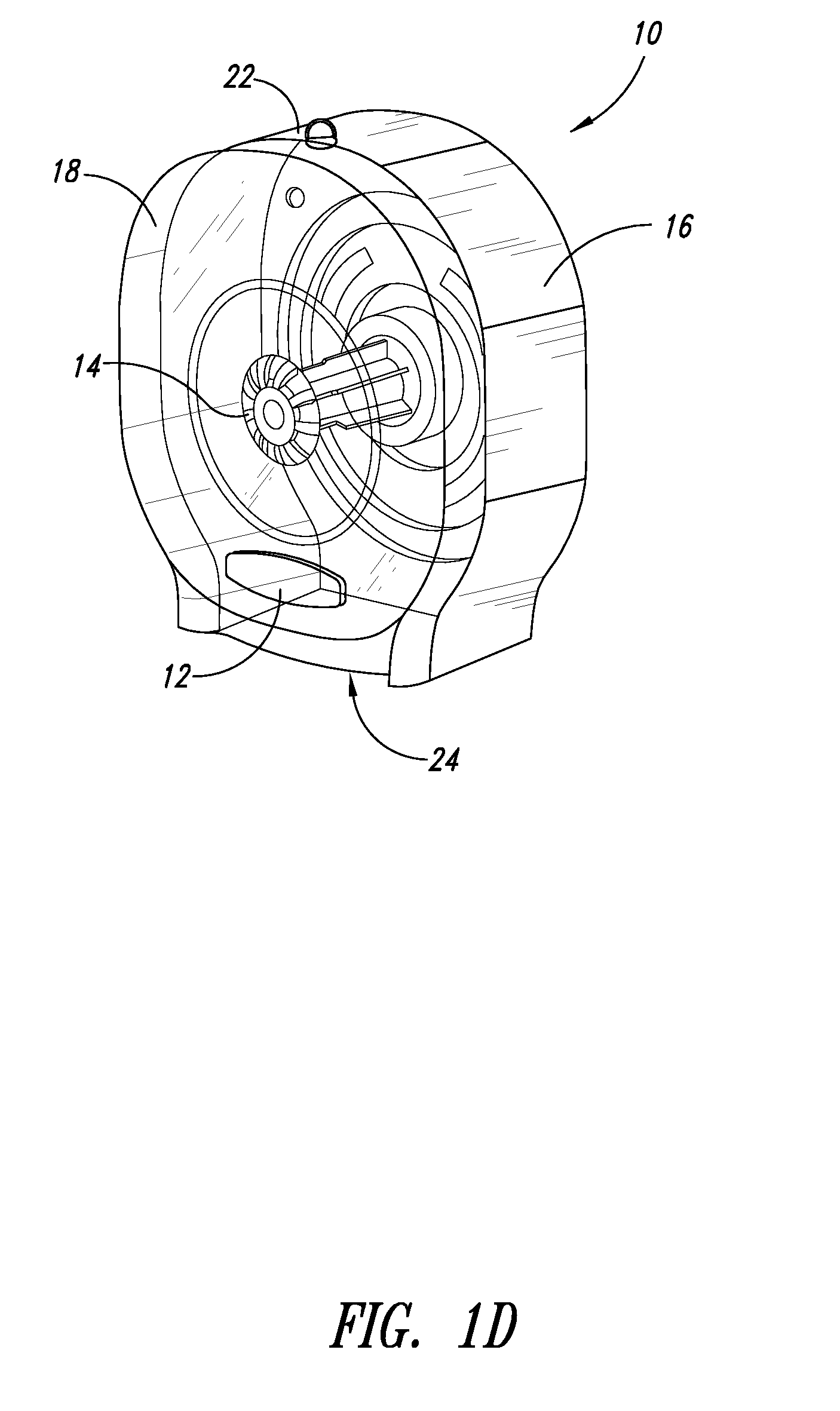

first embodiment

[0042] The surface of the drive roller 100 has a sufficient coefficient of friction to rotate the roll A when the motor 26 rotates the drive roller 100. The motor 26 is also movably mounted along the track 104 and is rotationally coupled to the drive roller 100 using the one way bearing and gears as described in the Alternatively, the motor 26 can be fixed to the housing 26 and rotationally coupled to the drive roller 100 using a series of gears and chain as is well known in the art (not shown).

[0043] Like the first embodiment, the drive roller 100 is coupled to the motor 26 by the one way bearing 36. Therefore, a user can manually operate the dispenser 10 either by pulling on the leading edge of the roll A, or turning the knob of the manual dispensing assembly 14, or both.

third embodiment

[0044] Referring to FIGS. 6(a)-(c) and 7 and according to the invention, the automated dispensing assembly of the dispenser 10 is modified so that the support 32 is rotatably coupled to the housing 16, and is driven by the motor 26. In other words, the support 32 acts as a drive roller, and is coupled to the motor 26 by the one way bearing and reduction gears as described in the previous embodiments. Like in the previous embodiments, the knob 14 is provided on the door 18 and is coupled to the support 32 such that rotation of the knob 14 by the user causes the support 32 to rotate and paper to be manually dispensed, whether or not the motor 26 is operating.

[0045] Because the roll A diameter diminishes as paper is dispensed, the length of toilet paper dispensed is not constant relative to the number of rotations of the roll support 32. Therefore, the dispenser 10 in this embodiment is provided with a roller sensor 50 which is in contact with the leading edge of the roll A. The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com