Coating with controlled grain size and morphology for enhanced wear resistance and toughness

a technology of grain size and morphology, applied in the direction of coatings, chemical vapor deposition coatings, coatings, etc., can solve the problems of increased toughness of coatings, difficult modification of conventional process adjustments, and inability to meet the requirements of hard and brittle materials with limited plasticity, etc., to achieve the effect of enhancing performance and wear resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043] This example demonstrates the effect of CO doping. CO doping was applied to obtain columnar and equiaxed structures with reduced and controlled grain sizes. The following four experimental coatings (referred to as coatings 1, 2, 3 and 4 ) were produced at a pressure of 70 mbar and at a temperature of 880° C. according to the process data given in Table 2. Compared with the U.S. Pat. No. 6,472,060, considerably lower amounts of doping were used except coating 4, which was produced according to prior art (U.S. Pat. No. 6,472,060). Coating 2 is deposited at a CO level of 0.8% and is composed of fine-grained columnar crystals. Coating 3 was deposited at CO doping level of 2.5% and is composed of equiaxed grains. In order to obtain equiaxed grain morphology above the nanograined region CO doping in the range of from about 2.0 to about 4.0%, preferably from about 2 to about 3% of the total gas flow can be used. The CO addition had to be controlled carefully so that the nanograined ...

example 2

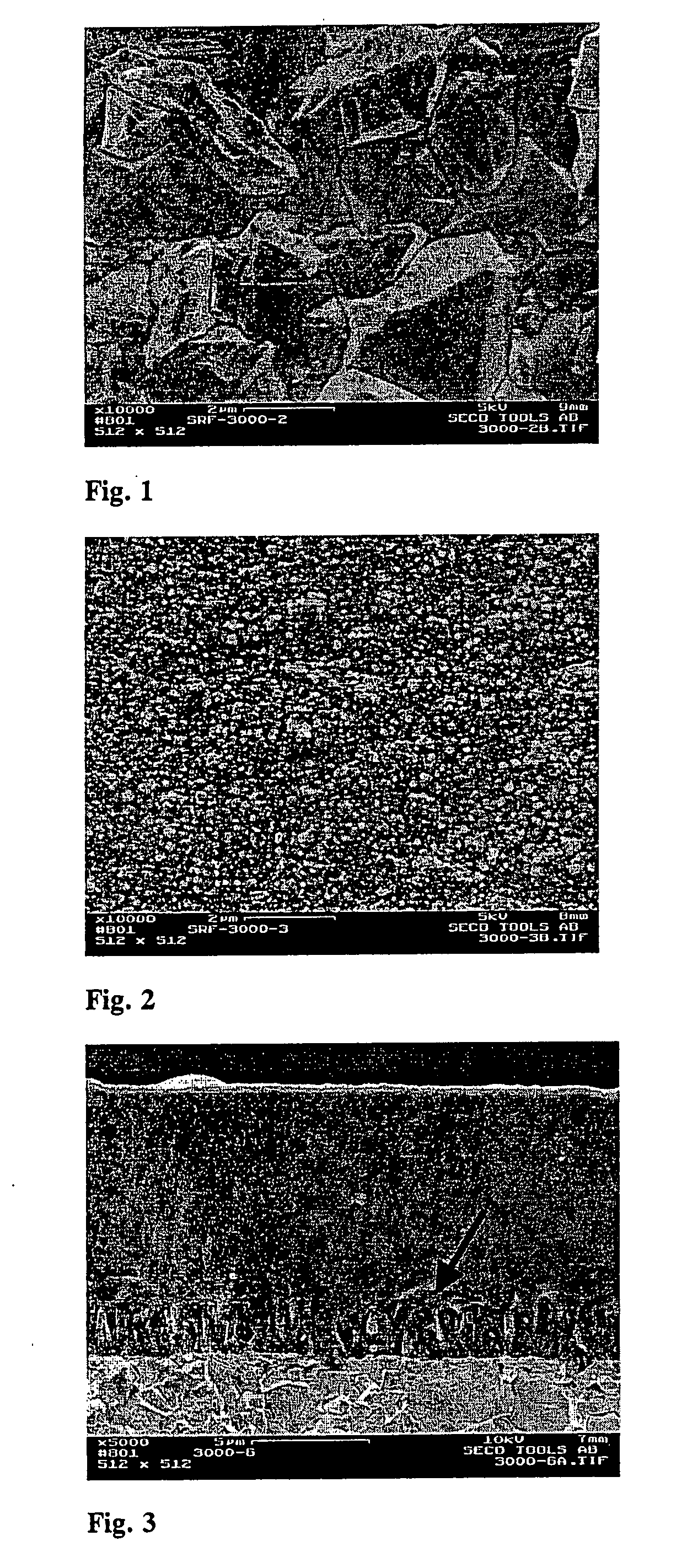

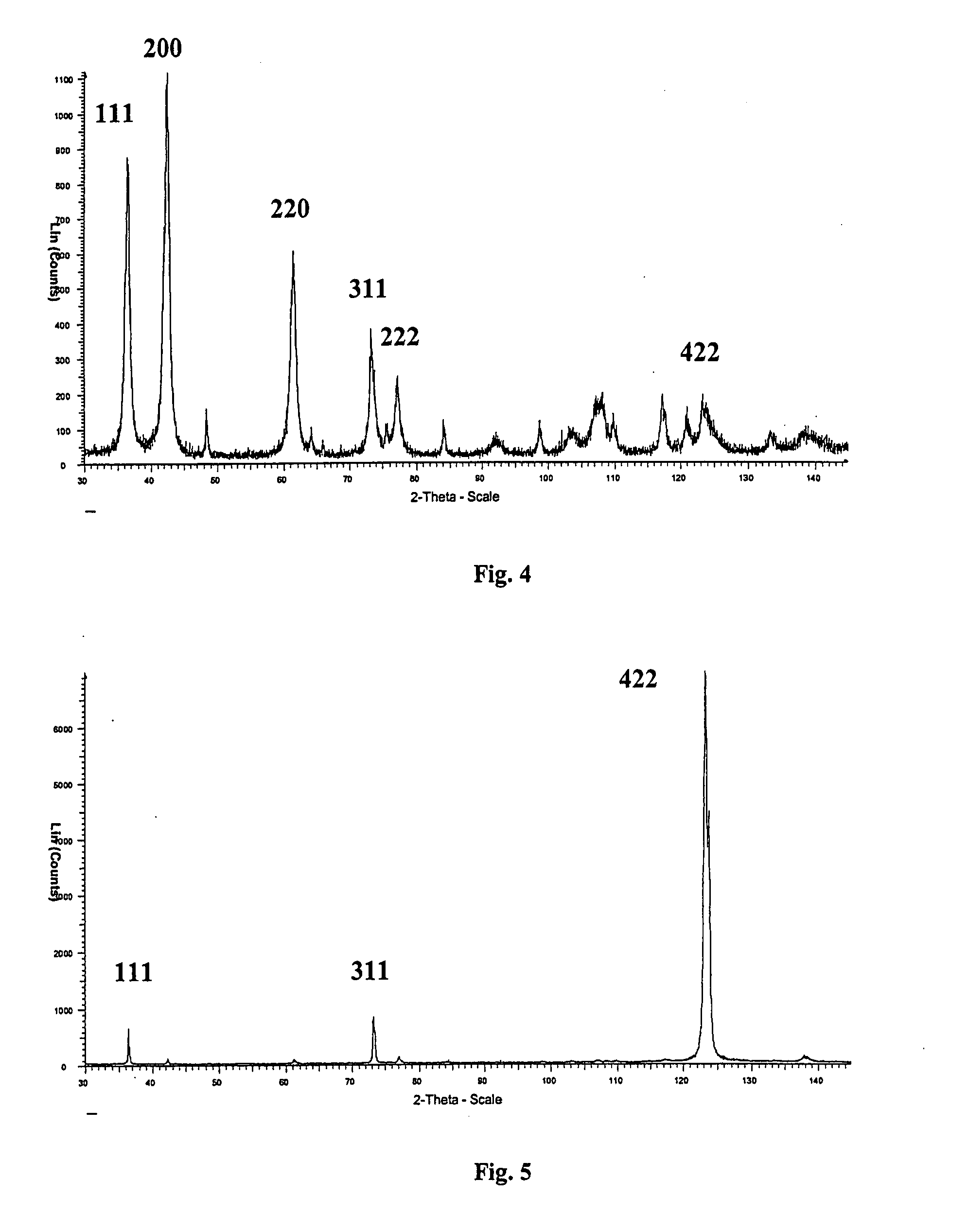

[0044] The coatings were investigated using Transmission electron microscopy (TEM) and Scanning electron microscopy (SEM) in order to elucidate the effect of CO doping on the grain size and morphology. It appeared clear even in SEM that the microstructure of the typical MTCVD Ti(C,N) coating being composed of large columnar crystals (FIG. 1) can be refined by CO doping. The equiaxed grain morphology was obtained at CO doping level of from about 2.5% (FIG. 2). TEM revealed that at this CO level the grain size was not brought into the nanograined region and was about 60 nm. The grain size of Coating 4 deposited according to prior-art was in the nanograined region. The results are summarized in Table 3.

TABLE 3Grain size*)MorphologyCoating 11500 × 4000nmLarge columnarCoating 290 × 650nmNeedle-likeCoating 360nmSmall-equiaxedCoating 414nmNanograined

example 3

[0045] This example demonstrates the deposition of equiaxed grain morphology with controlled grain sizes. The effects of ZrCl4 and AlCl3 on the grain size and morphology with and without CO / CO2 doping are demonstrated.

TABLE 4H2N2CH3CNTiCl4ZrCl4(1 / min)(1 / min)(1 / min)(l / min)(%)AlCl3(%)CO2(%)CO(%)Coating 5balance45.50.552.12.50.00.00.0Coating 6balance45.50.552.10.70.00.02.1Coating 7balance45.50.552.10.01.50.03.0Coating 8balance45.50.552.10.03.00.23.0Coating 9balance45.50.552.12.50.00.23.0Coating 10balance45.50.552.12.53.00.23.0

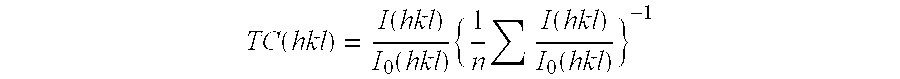

[0046] The structure of coating 5 is shown in FIG. 3. The first part (about 2 um) was deposited without ZrCl4 doping. As very clear from the FIG. 4 the addition of 2.5% of ZrCl4 changed the coating morphology from columnar to equiaxed one (arrowed). Lower additions of ZrCl4 are needed to obtain the same structure as in Coating 5, if ZrCl4 is applied simultaneously with CO (coating 6). The same type of behavior could be obtained by adding AlCl3 together with CO (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com