Methods and apparatus for cleaning edges of a substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

[0019] The invention is directed to apparatus and methods for processing or cleaning a workpiece, such as a semiconductor wafer. The term workpiece or wafer here means any flat article, including semiconductor wafers and other substrates such as glass, mask, and optical or memory media, MEMS substrates, or any other workpiece having, or on which, microelectronic, micromechanical, microelectro-mechanical or micro-optical devices can be formed. The term contaminant here means any unwanted particles, film or other material on a wafer.

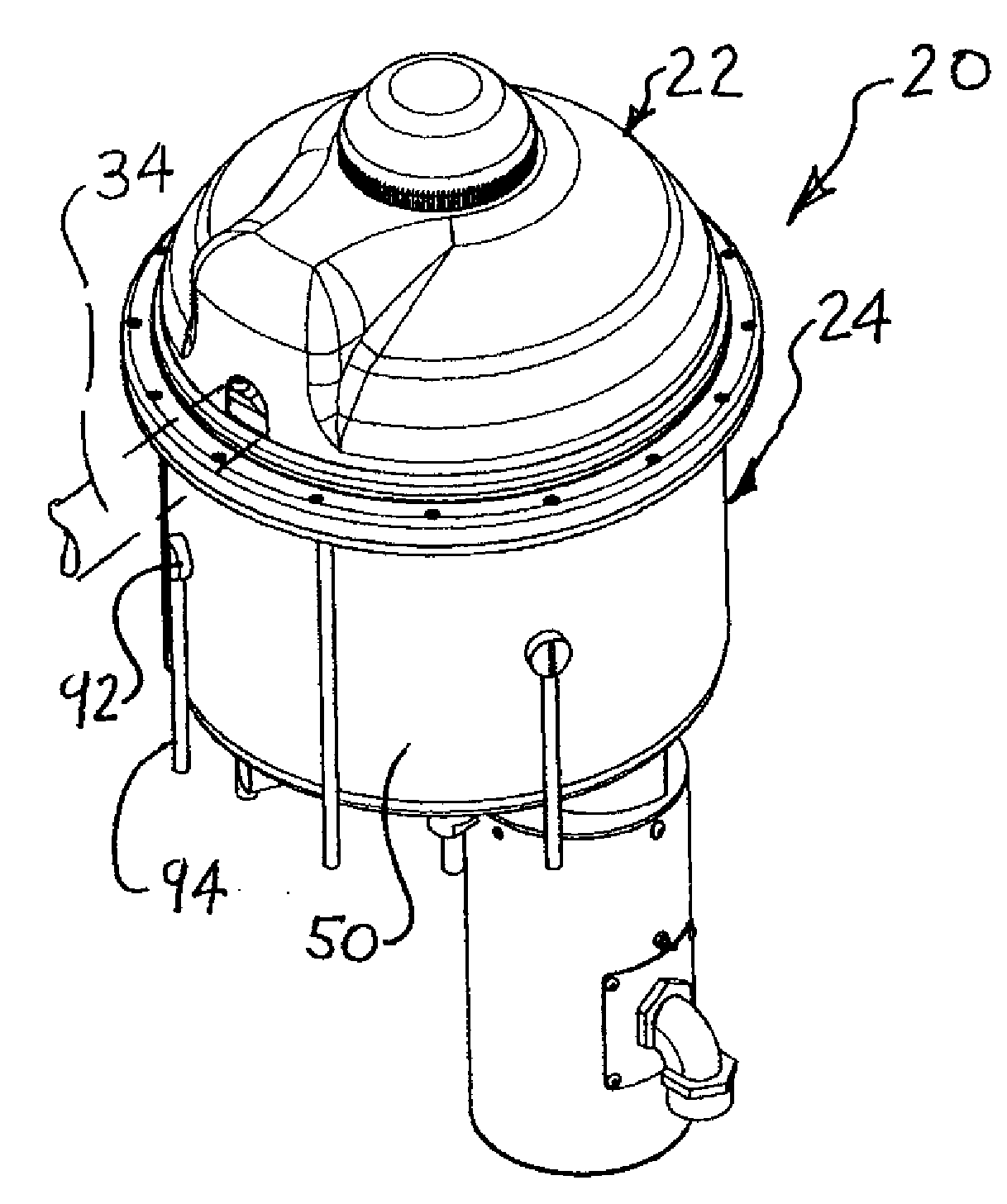

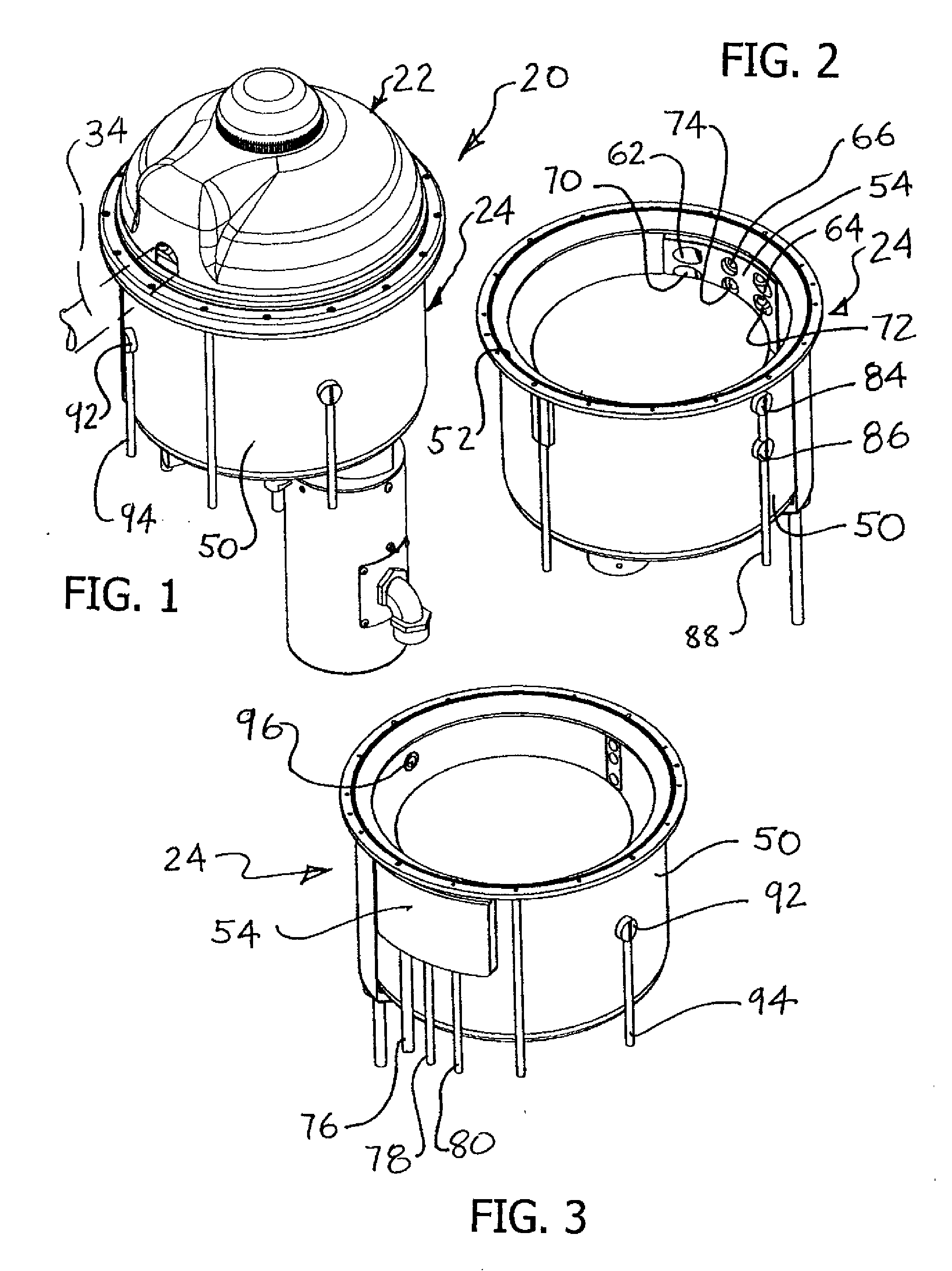

[0020] Turning now to FIGS. 1-3, a processor 20 has a head 22 which may be moved into and out of engagement with a base 24. The base 24 includes a bowl 50 which may have generally cylindrical side walls.

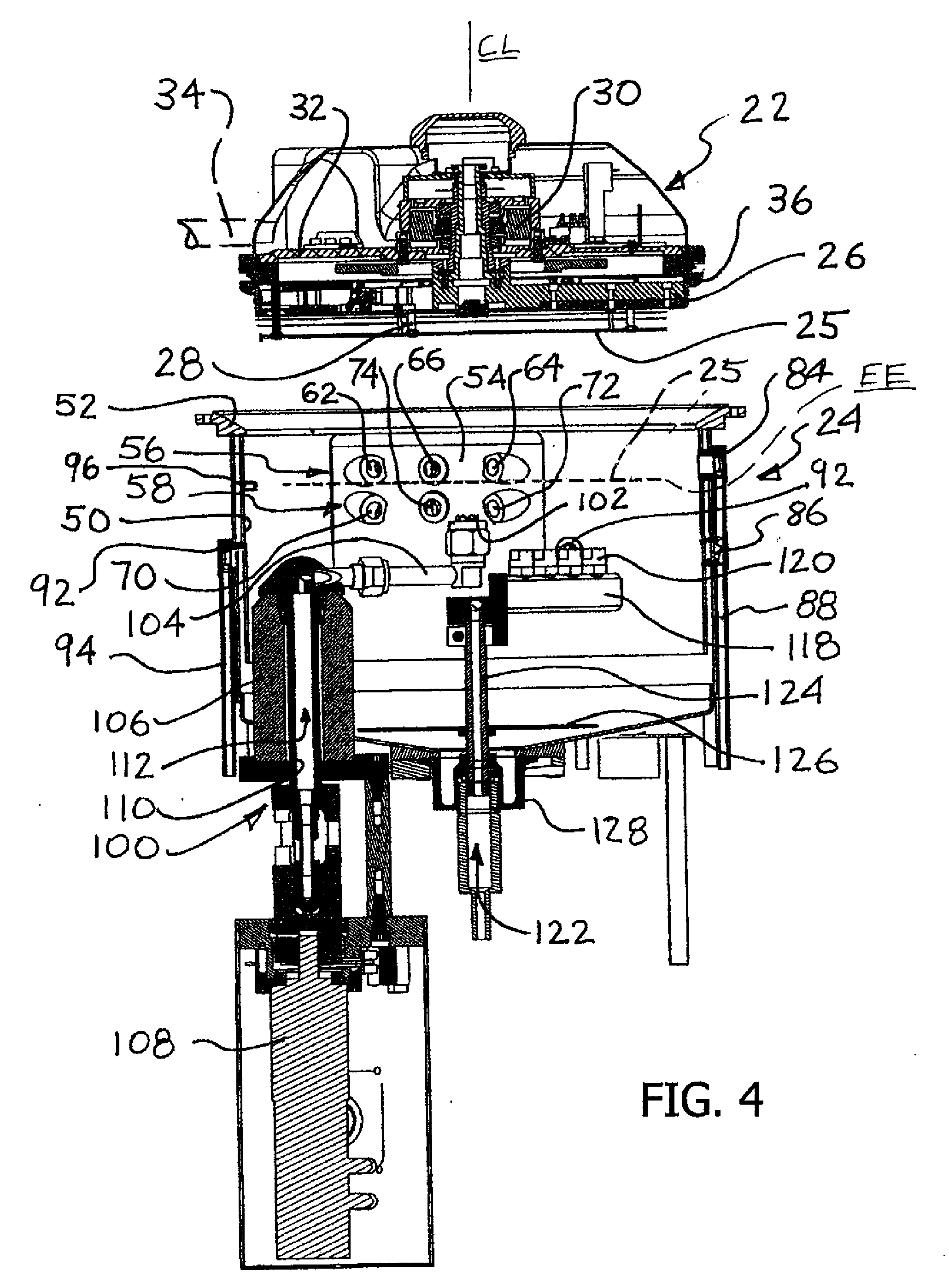

[0021] Turning to FIG. 4, the head 22 typically includes a rotor 26 rotatably supported by a head frame 32. A motor 30 in the head 22 is adapted to spin the rotor 26. Fingers or retainers 28 on the rotor 26 hold a wafe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com