Articulating dunnage and method of use

a dunnage and articulation technology, applied in the field of dunnage, can solve the problems of void between the corner of the container and the dunnage, and achieve the effects of reducing localized stretching, reducing dunnage cost, and reducing dunnage cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

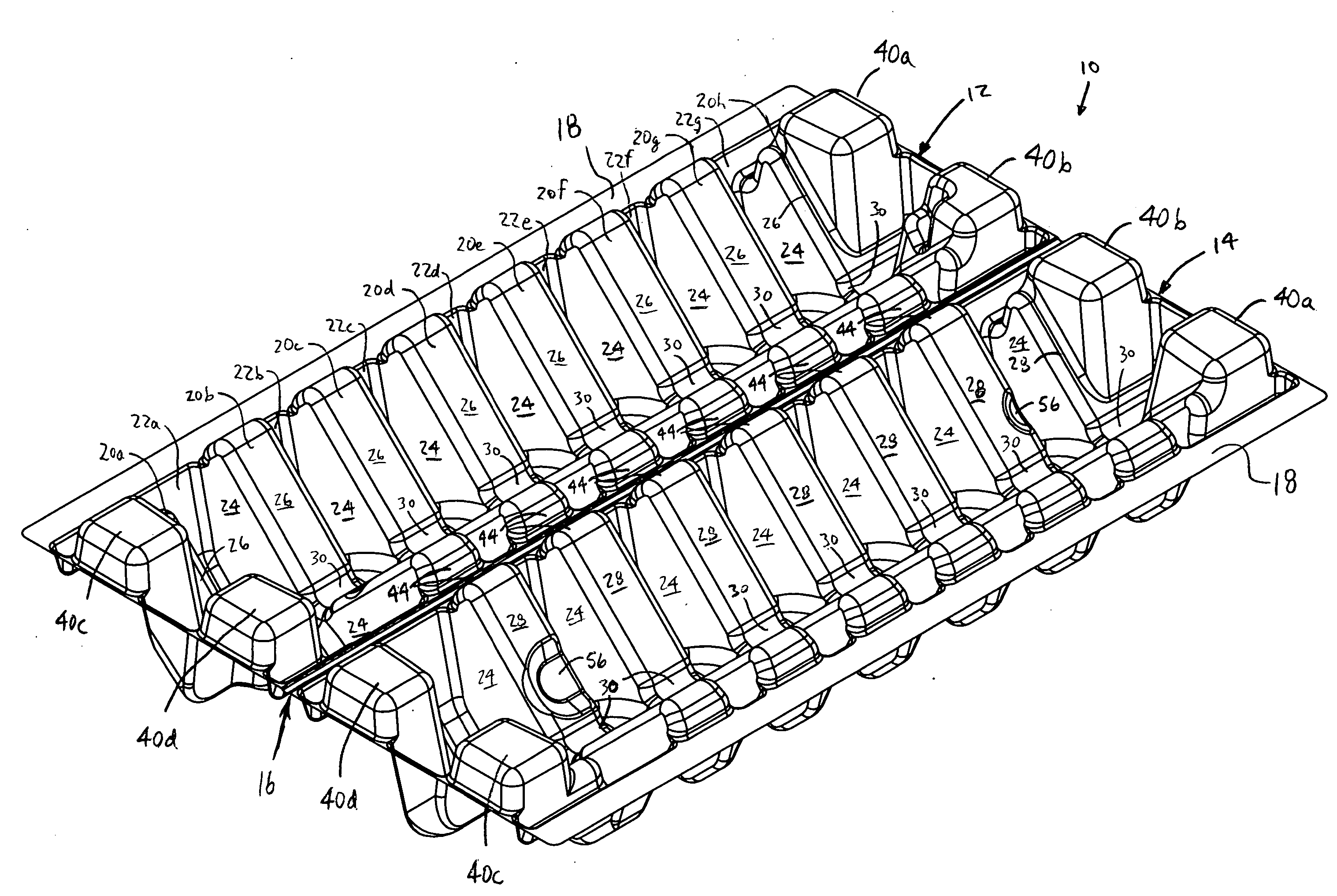

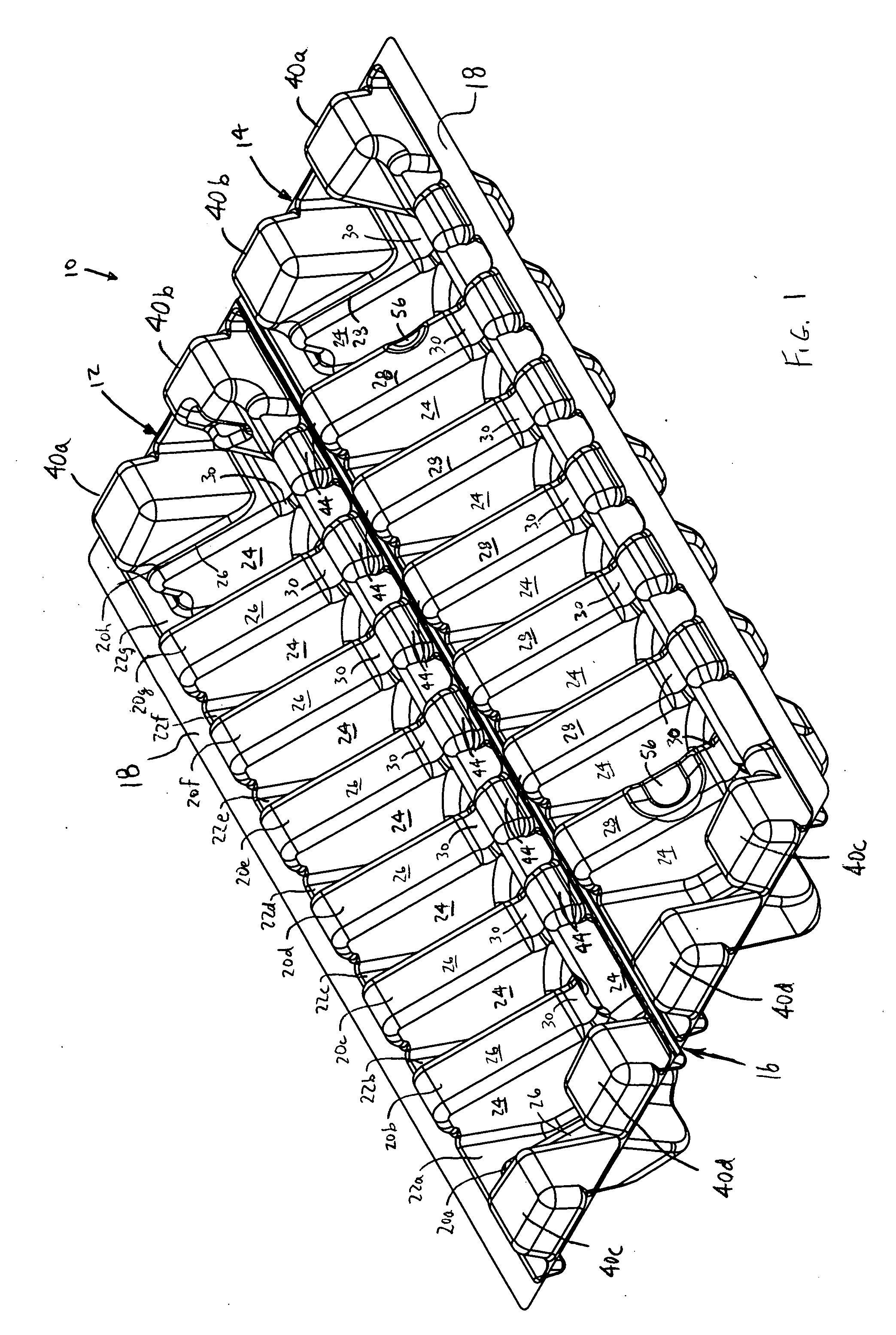

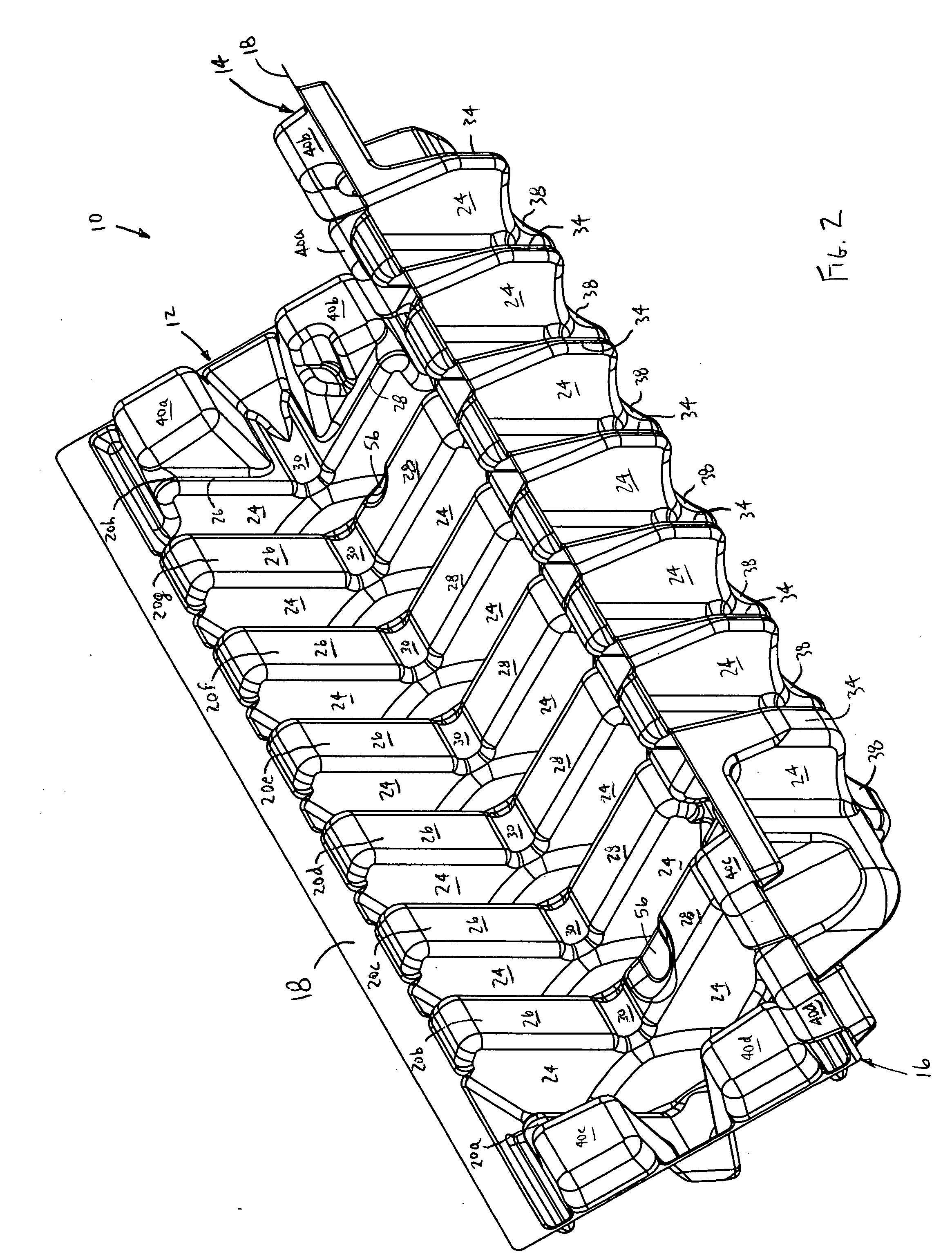

[0029] Articulating dunnage in accordance with an embodiment of the present invention is shown in FIGS. 1-4, and is generally designated 10. As shown, the dunnage 10 includes two corner support portions 12 and 14 that are joined along a living hinge 16. The dunnage 10 is selectively movable between an open configuration (See FIGS. 1 and 3) to a closed configuration (See FIGS. 2 and 4) about the living hinge 16. Referring now to FIGS. 5-8, the dunnage 10 is configured to closely receive the article A and to be closely fitted into the container C between adjacent corners. In this embodiment, the article A is packaged in the container C with separate pieces of dunnage 10 and 10′ over the top and bottom of the article A. As perhaps best shown in FIG. 8, the dunnage provides a protective packaging shell between portions of the container C and the article A. The present invention also provides a method for packaging articles A in a container C using articulating dunnage 10. In general, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| forces | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shape memory | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com