Method for producing decorative stone

a technology of decorative stone and method, which is applied in the field of decorative stone, can solve the problems of inability to industrialize, work pieces that cannot be machined accurately during manufacturing, and known machine patterns that cannot machine work pieces as various predetermined shapes without penetrating the workpiece, etc., and achieve the effect of increasing the decorative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for producing a decorative stone in accordance with a preferred embodiment of the present invention includes steps as follows:

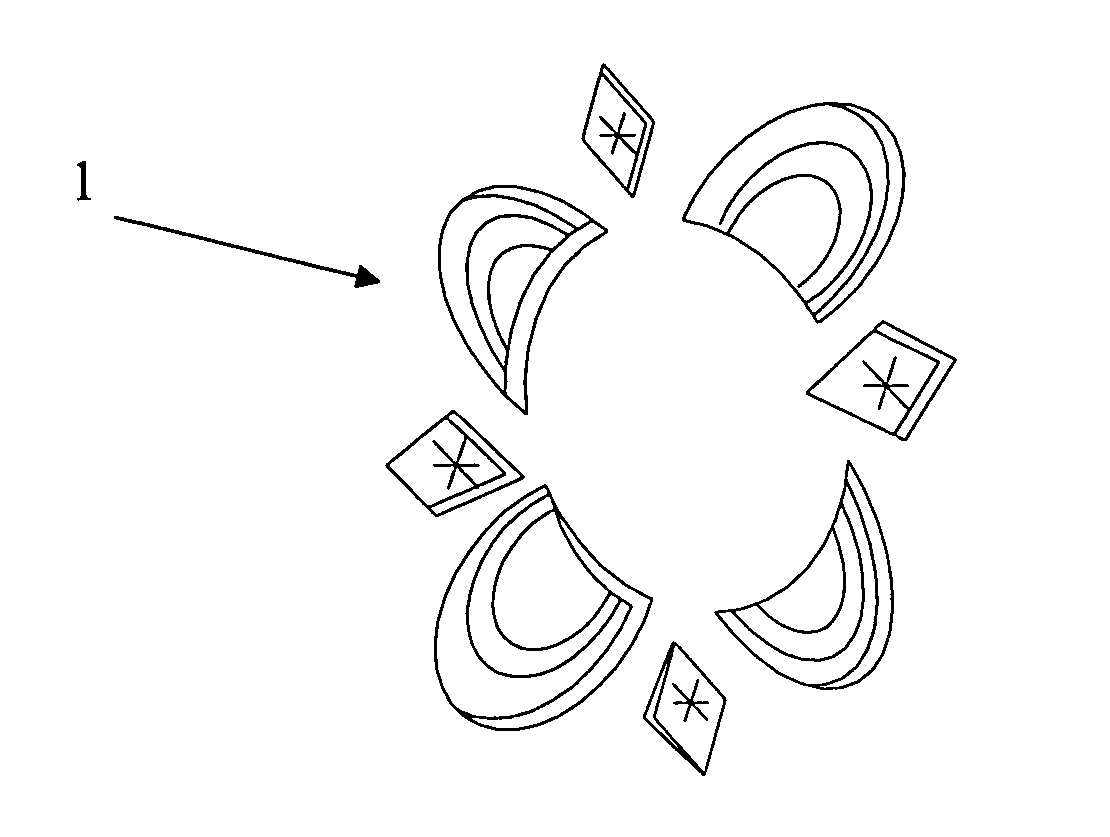

[0015] At the step 1, referring to FIG. 1, on the basis of requirements of different designs, various metal molds (namely the first metal molds) are used for cutting a stone (or other decorative materials) into certain positive pieces 1 having various shape by the water-jet technology.

[0016] Then turn to the step 2, making another set of metal molds (namely the second metal molds) which have the same shape as the first metal molds but a bit smaller size. Using the second metal molds to cut another stone to certain depth. It should be note that here the cut is not through, only to certain depth. The actual depth depends on the shape and the design. Since the second metal molds have a thickness themselves, the cut-off pieces is a little larger than the positive pieces 1.

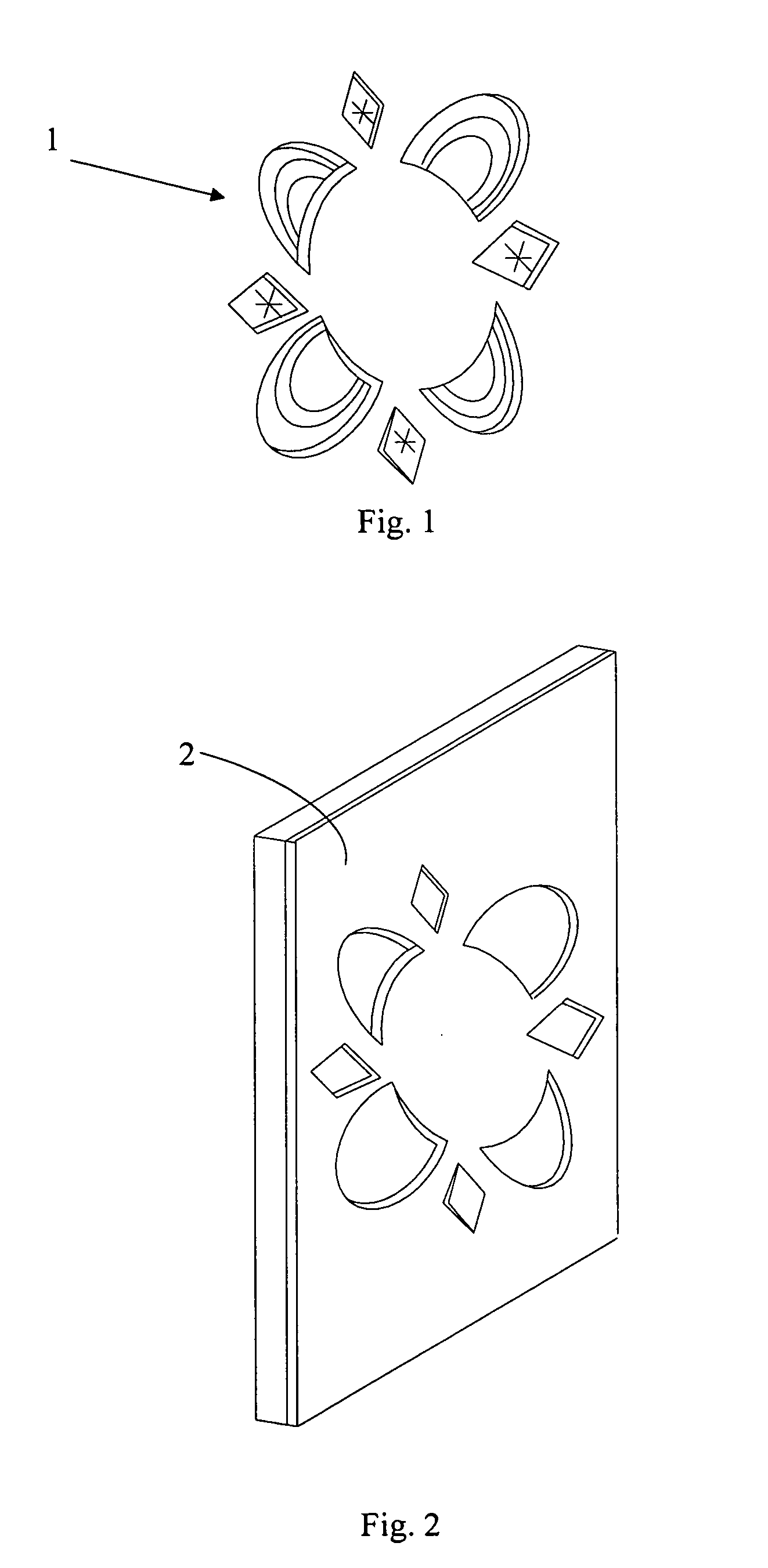

[0017] At the step 3, referring to FIG. 2, taking out the cut-off pieces ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com